A method for realizing gear shifting process in vehicle drive train

A technology for power trains and vehicles, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as multiple shift times, achieve the effect of mild speed synchronization and save shift time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

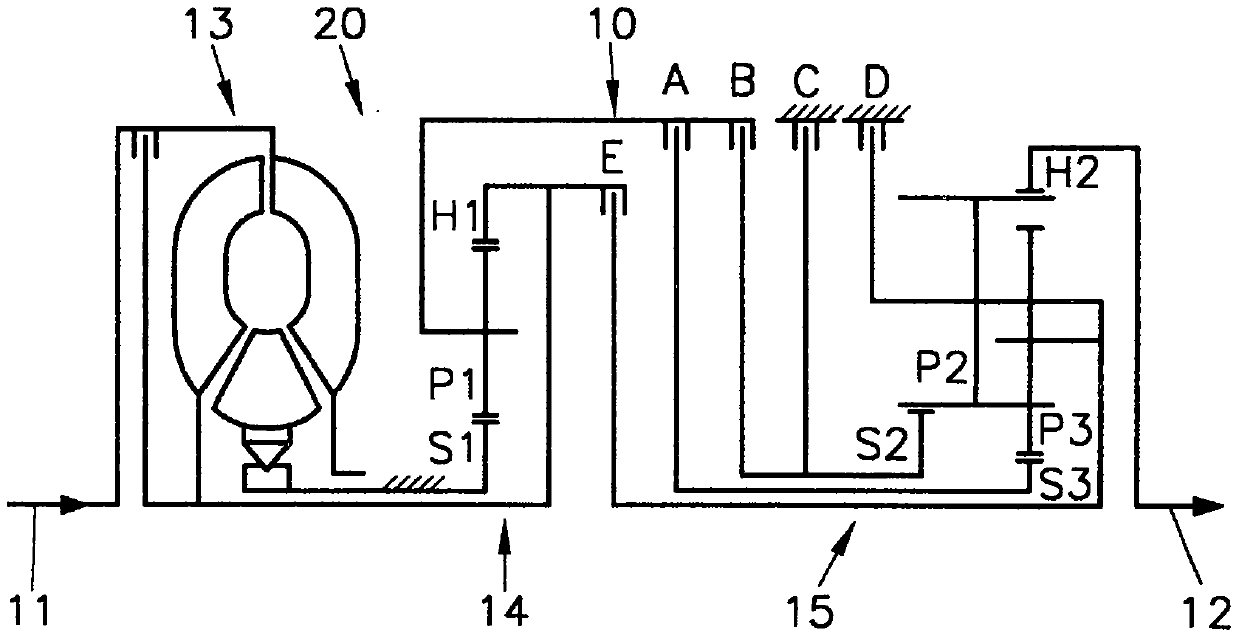

[0030] figure 1 Shown is a motor vehicle drive train 20 arranged between an input shaft 11 and an output shaft 12 with a motor vehicle transmission 10 and a torque converter 13 , which drive train 20 is suitable for carrying out the method according to the invention. A drive machine, not further shown, such as an internal combustion engine, is connected to the input shaft 11 , and a vehicle output, not further shown, is connected to the output shaft 12 . The vehicle transmission 10 formed as an automatic transmission, for example, has a first planetary gear train 14 and a second planetary gear train 15, a first shifting element A, a second shifting element B, a third shifting element C, a fourth shifting element D, and a fifth shifting element. Shifting element E, wherein the second planetary gear train 15 is formed as a Ravigneaux gear set. In this exemplary embodiment, the shift elements A, B, E are formed as shifting clutches, and the shift elements C, D are formed as brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com