Range hood provided with cooking fume guide plate

A range hood and smoke deflector technology, which is applied in the field of range hoods to improve the effect of range hoods and solve oil circuit problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

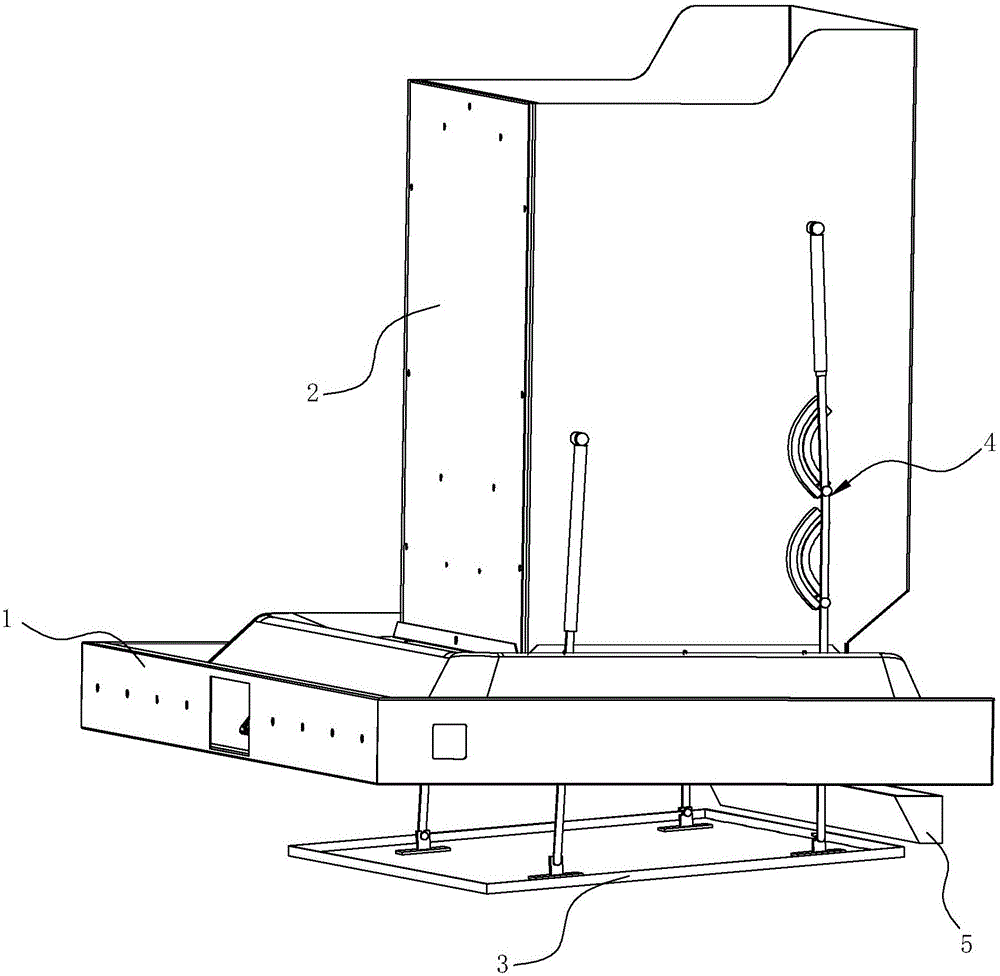

[0036] see Figure 1 to Figure 6 , a range hood with a smoke guide plate, including a smoke collection hood 1 formed with a smoke collection chamber, a fan cover 2 and a smoke guide plate 3, the smoke guide plate 3 can use the existing technology, as described in the background technology , and it is arranged directly below the air inlet opening on the fume collecting hood 1 . The left and right sides of the fan cover 2 are provided with a lifting mechanism 4 for driving the smoke guide plate 3 to rotate and lift. An oil cup 5 is arranged below the smoke collecting hood 1 at the rear side of the smoke guide plate 3 .

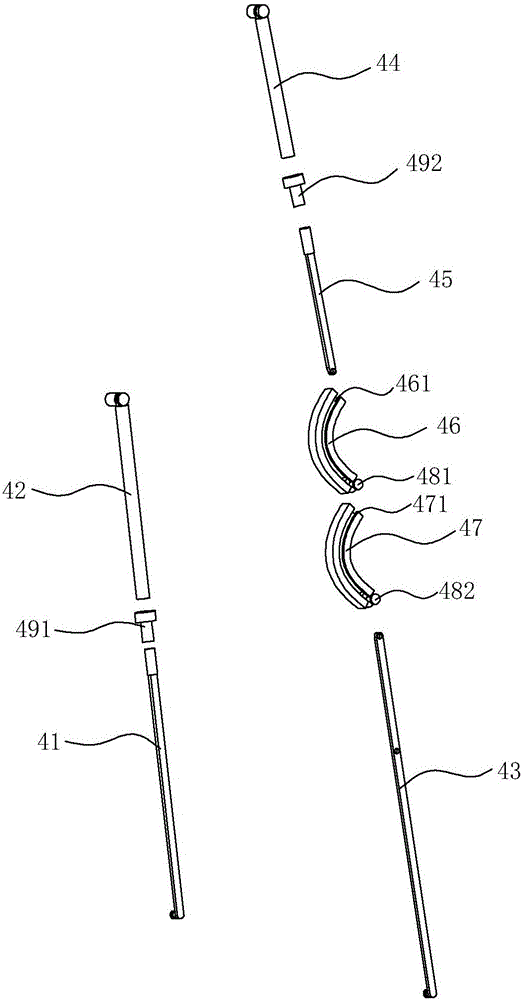

[0037] The lifting mechanism 4 includes a first lifting mechanism at the front and a second lifting mechanism at the rear. The first lifting mechanism includes a first push rod 41 and a first shaft sleeve 42. The top of the first shaft sleeve 42 is in contact with the fan cover 2 The side wall of the first push rod 41 is rotatably connected, the upper part of ...

Embodiment 2

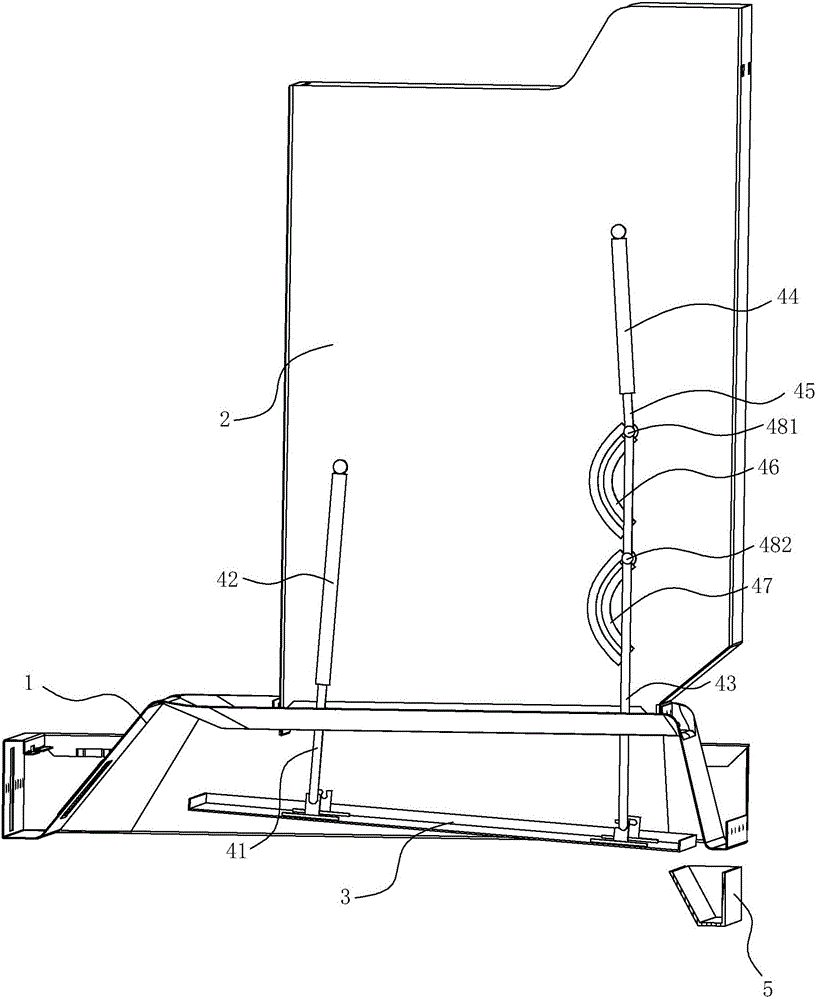

[0043] see Figure 7 ~ Figure 11 , in this embodiment, the difference from the first embodiment above is that the second lifting mechanism includes a second push rod 43, a second bushing 44, a connecting rod 45, a transmission rod 46', and is arranged behind the second push rod 43. The first rocker 47' and the second rocker 48' on the side, the second shaft sleeve 44 is connected with the side wall of the fan cover 2 to keep vertical, the upper part of the connecting rod 45 is inserted in the second shaft sleeve 44, and the connecting rod 45 The lower end of the second push rod 43 is rotatably connected to the upper end of the second push rod 43 through a transmission rod 46 ′, and the lower end of the second push rod 43 is rotatably connected to the rear of the smoke guiding plate 3 . One end of the first rocking bar 47' is rotatably connected with the side wall of the fan cover 2, and the other end is rotatably connected with the upper end of the second push rod 43; one end ...

Embodiment 3

[0046] see Figure 12 to Figure 16 , in this embodiment, the difference from the first embodiment above is that the connecting rod and bushing of the second elevating mechanism are replaced by a gear transmission mechanism, including first gears 44 ″ arranged at intervals up and down, located between two first gears 44 "The second gear 45" between ", and the second push rod 43. The second gear 45" meshes with the two first gears 44' respectively, and the second push rod 43 is eccentric with the two first gears 44" respectively. The positions are connected, the first gear 44" enables the second push rod 43 to move forward and backward during the movement, and keeps the second push rod 43 always vertical during the movement. In this embodiment, the driving mechanism is a motor, which can drive one of the first gears 44" to rotate.

[0047] The movement mode of the smoke guiding plate 3 is as shown in the first and second embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com