Joint sealing sleeve for bus duct pouring

A sealing sleeve and busway technology, which is applied in the direction of docking busbars, busbar installation, fully enclosed busway devices, etc., can solve the problems of difficult pouring of poured busway, unreliable connection and sealing of prefabricated silicone rubber sealing bolts, etc., to achieve simple installation, Solve the effect of prefabricated silicone rubber sealing bolt connection and easy sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

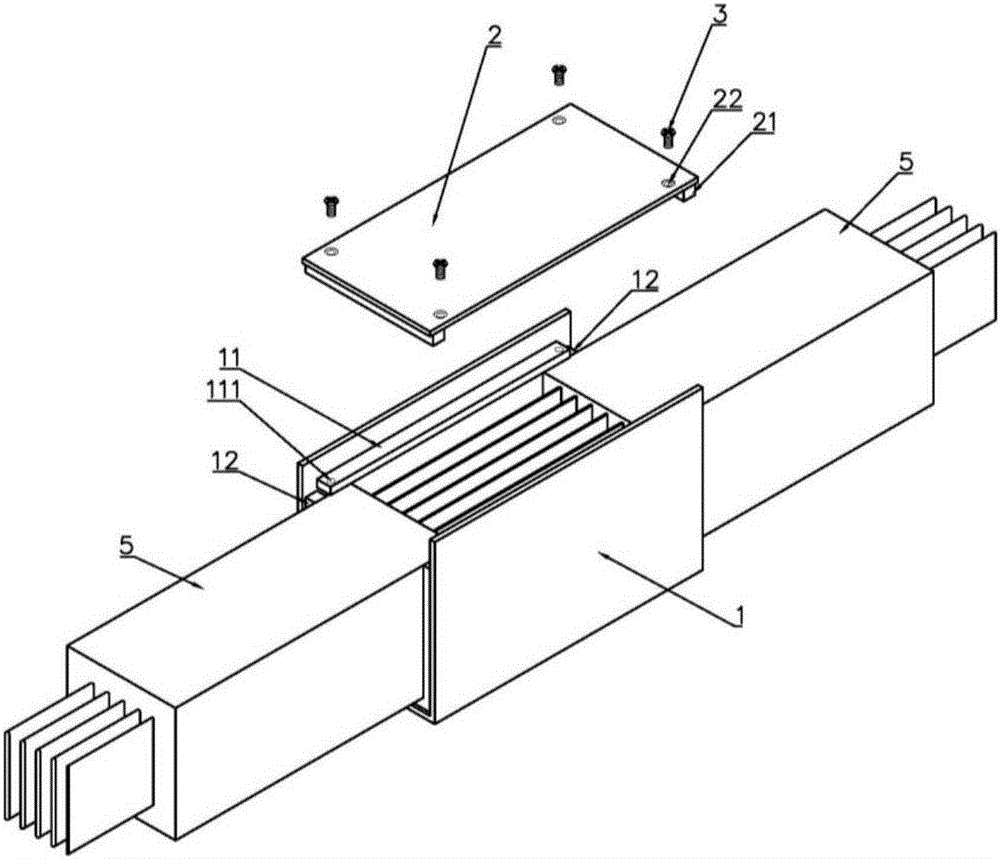

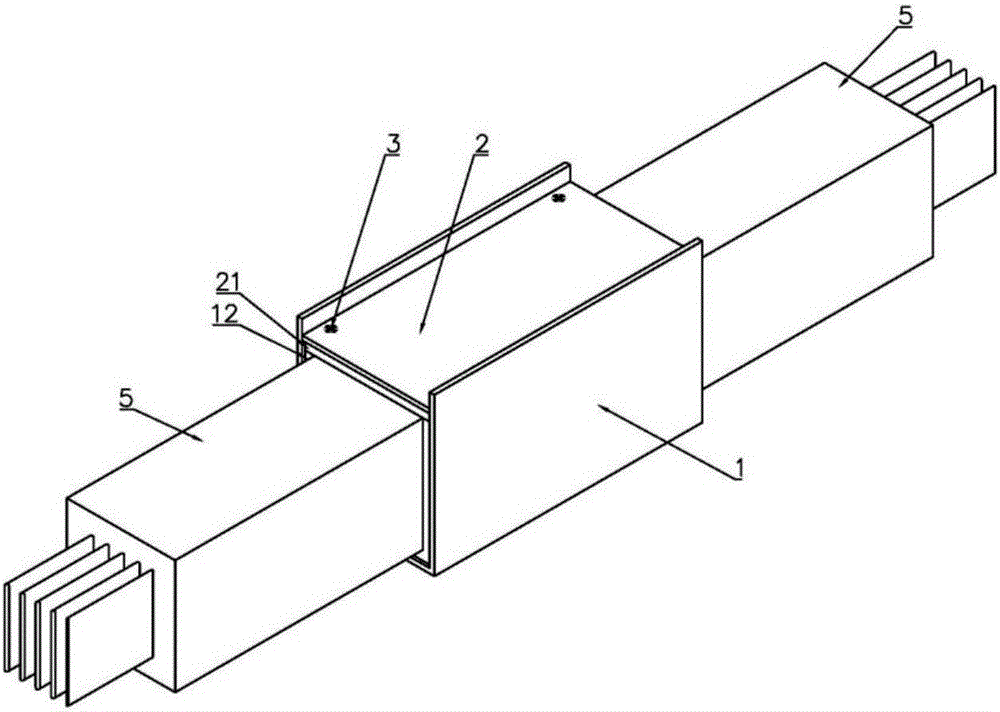

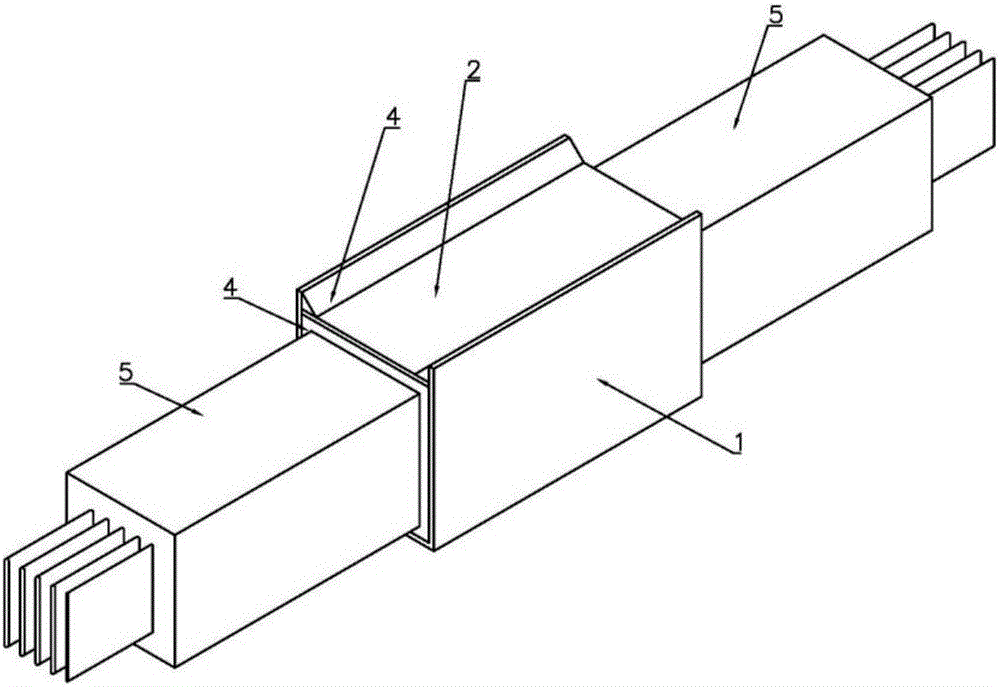

[0011] The sealing sleeve of the cast bus duct joint of the present invention is made of metal materials. The width and height of the sealing sleeve are 5 to 25 mm larger than those of the bus duct body, and the length covers part of the pouring parts at both ends of the joint. The sealing sleeve is divided into two parts, the groove and the cover, in which there is a metal connecting strip on both sides of the inner side of the upper opening of the groove body, and each metal connecting strip is provided with no less than 2 threaded holes, and the cover plate is provided with threads for the metal connecting strip The position and quantity of the holes correspond to the countersunk head bolt holes, and the inner ends of the tank body and the cover plate are respectively equipped with sealing rubber strips. When the busway is installed, after the joints are connected, put the sealing sleeve tank body outside the joint, and then fasten the cover plate of the sealing sleeve with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap