A method for decorating the blind hole surface of a transparent display panel

A transparent display panel, blind hole technology, applied in the process of producing decorative surface effects, decorative arts, input/output process of data processing, etc., can solve the problem of uneven line thickness, poor printing quality, size Not good and other problems, to achieve the effect of clear outline, complete uniformity and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

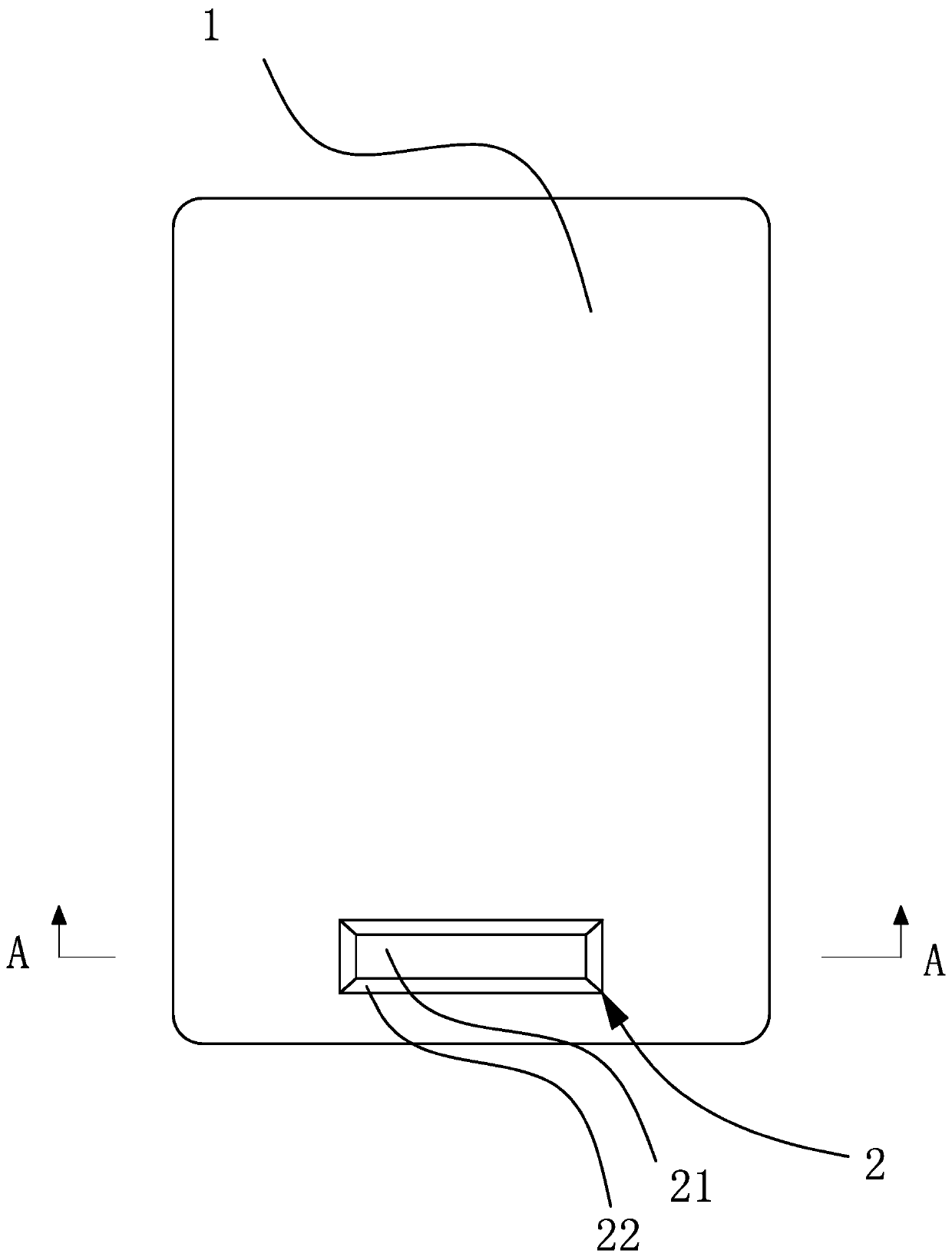

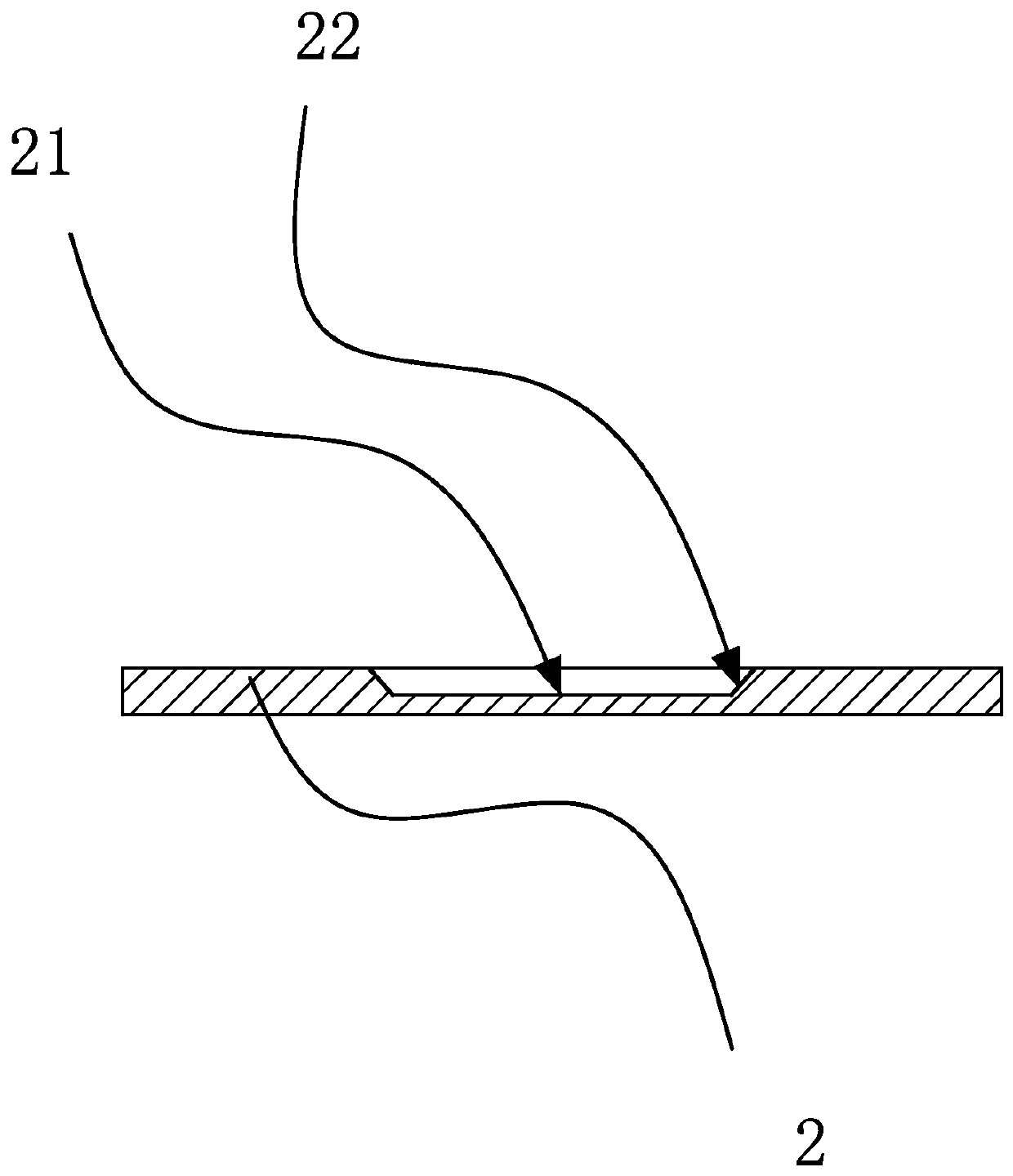

[0025] In this embodiment, the glass panel of the mobile phone display screen is used as the specific implementation, and the specific decoration method is as follows:

[0026] According to the size of the display screen of the mobile phone, a transparent display panel 1 with a blind hole 2 is selected, which is made of glass, and the side with the blind hole 2 is usually called the back side, wherein the bottom surface 21 of the blind hole 2 is the same as the bottom surface of the blind hole 2. The included angle between the side wall surfaces 22 is 140°C. The ink is printed on the bottom surface 21 of the blind hole 2 by silk screen printing. The ink can use conventional raw materials. As for the color of the ink, it can be selected according to actual needs, such as white or black, etc., after printing, control the temperature at 150 ° C for 30 minutes to bake, so that an ink layer is formed on the bottom surface 21 of the blind hole 2 after drying; then, on the side wall s...

Embodiment 2

[0028] In this embodiment, the PMMA panel of the display screen of the mobile phone is used as the specific implementation, and the specific decoration method is as follows:

[0029] According to the size of the display screen of the mobile phone, a transparent display panel 1 with a blind hole 2 is selected, which is made of PMMA material. Usually, the side with the blind hole 2 is called the back side, wherein the bottom surface 21 of the blind hole 2 is connected with the blind hole 2. The included angle between the side wall surfaces 22 of the blind hole 2 is 120°C. The ink is printed on the bottom surface 21 of the blind hole 2 by silk screen printing. The ink can use conventional raw materials. As for the color of the ink, it can be selected according to actual needs, such as White or black, etc., after printing, control the temperature at 120 ° C for 30 minutes to bake, so that an ink layer is formed on the bottom surface 21 of the blind hole 2 after drying; then, on the...

Embodiment 3

[0031] In the present embodiment, take the PMMA panel of the tablet computer display screen as the specific implementation, and the specific decoration method is as follows:

[0032] According to the size of the display screen of the tablet computer, a transparent display panel 1 with a blind hole 2 is selected, which is made of PMMA material, and the side with the blind hole 2 is usually called the back side, wherein the bottom surface 21 of the blind hole 2 is in contact with the blind hole. The included angle between the side wall surfaces 22 of the blind hole 2 is 150°C. The ink is printed on the bottom surface 21 of the blind hole 2 by silk screen printing. The ink can use conventional raw materials. As for the color of the ink, it can be selected according to actual needs, such as White or black, etc., after printing, control the temperature at 120 ° C for 30 minutes to bake, so that an ink layer is formed on the bottom surface 21 of the blind hole 2 after drying; then, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com