Agricultural baler with auxiliary power system

一种辅助动力、打捆机的技术,应用在农业机械和机具、农业、打包等方向,达到减少燃料消耗、大舒适度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

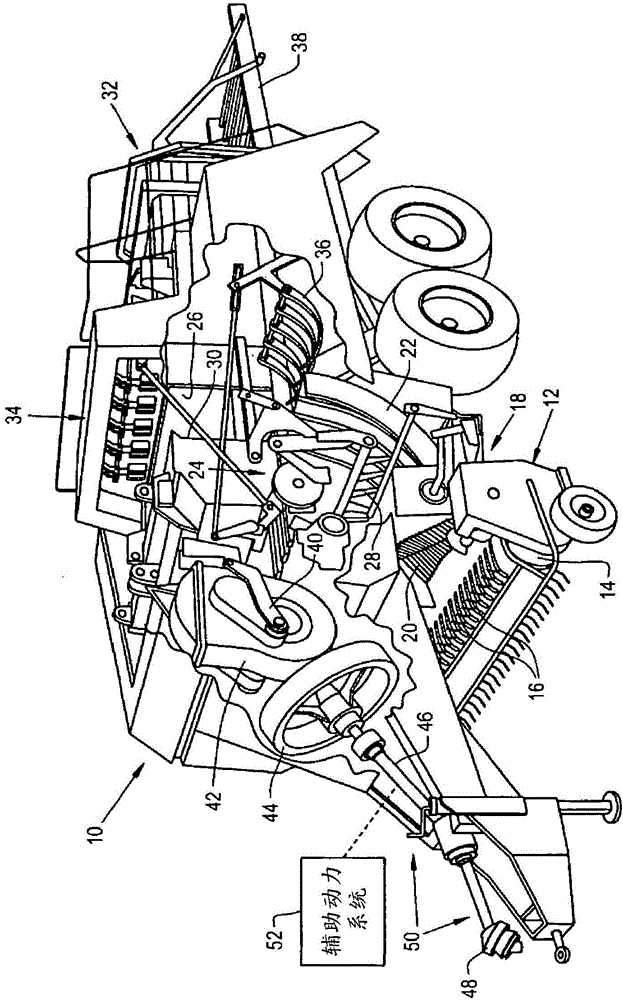

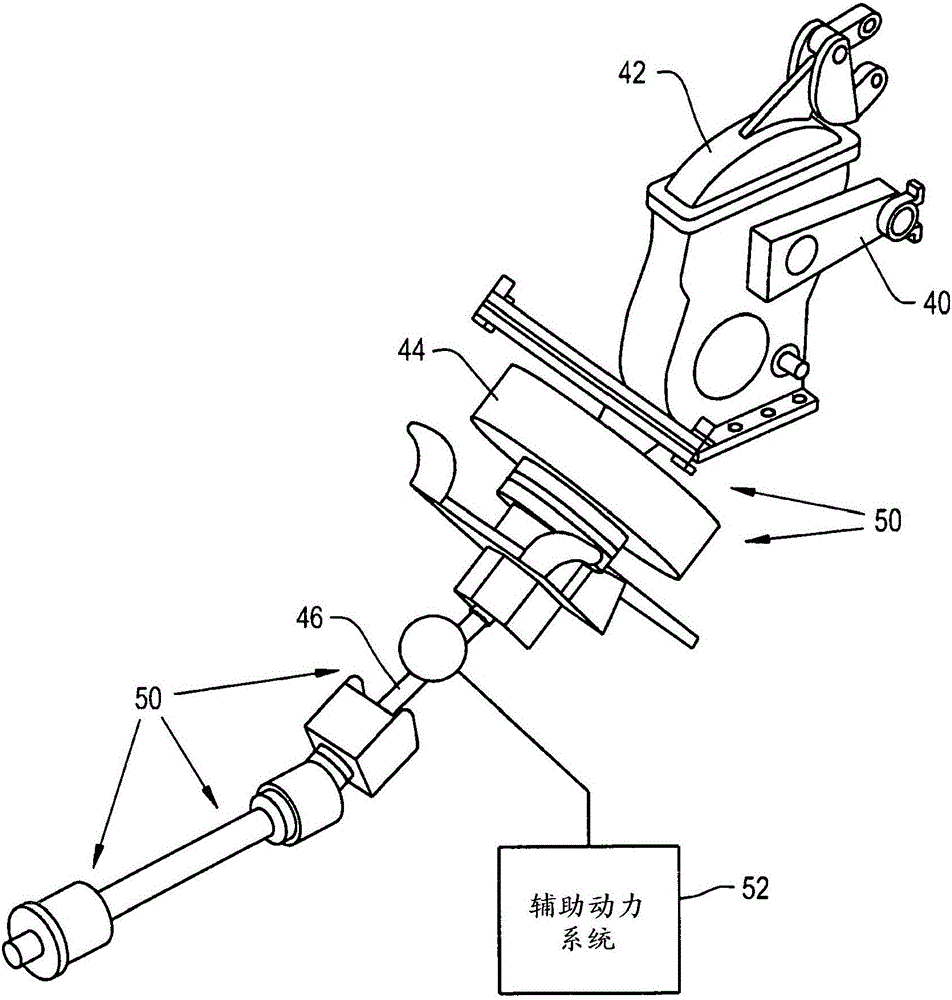

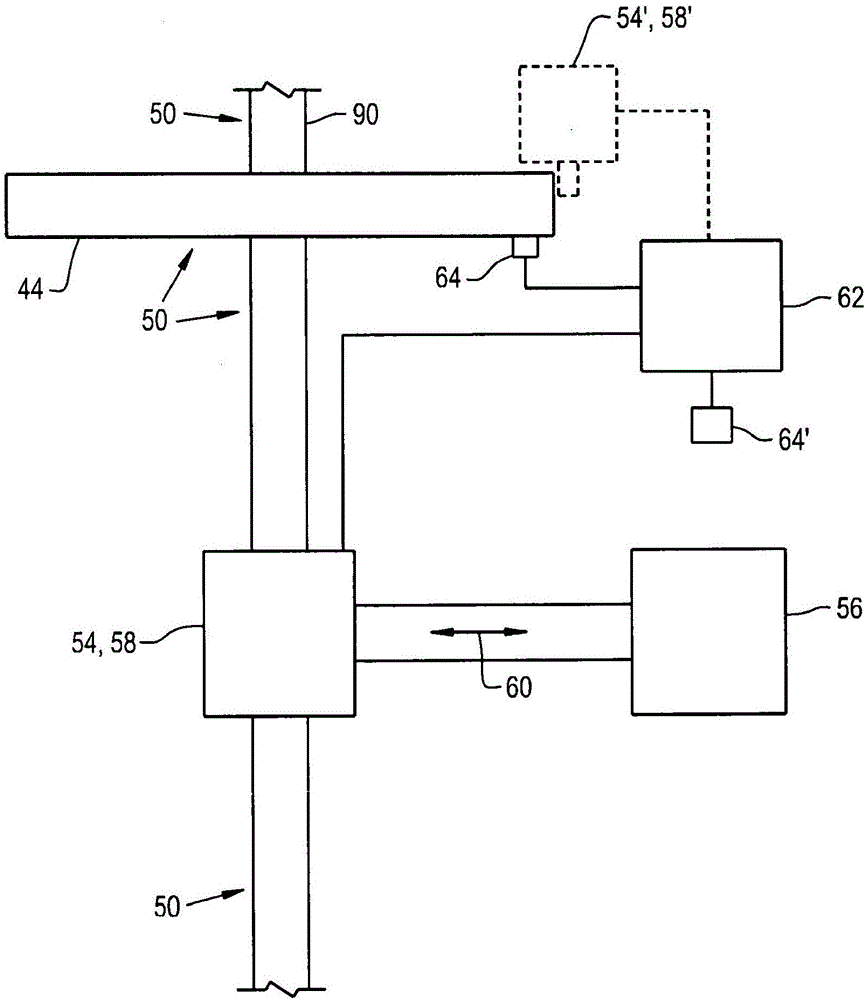

[0025] Referring now to the drawings, and more particularly to figure 1 , shows a perspective cutaway view showing the inner workings of the large square bale baler 10 . The baler 10 operates on a two-stage feed system. The crop material is lifted from the stockpile into the baler 10 using the pick-up unit 12 . The pick unit 12 includes a rotating pick roller 14 with tines 16 which move the crop rearwardly towards a baler unit 18 . An optional pair of short augers (one of which is shown but not numbered) is located above the pick-up roller 14 to move the crop material laterally inward. The baler unit 18 includes baler tines 20 that push the crop into a pre-compression chamber 22 to form bales of crop material. The baler tines 20 wind the crop together and pack the crop within the pre-compression chamber 22 . The pre-compression chamber 22 and baler tines 20 serve as the first stage for crop compression. Once the pressure in the pre-compression chamber 22 reaches a predete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com