Aerosol generating system with a rupturing system for a container

An aerosol generation and container technology, applied in the field of puncture system, can solve the problems of failure of puncture components, increase of manufacturing complexity and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

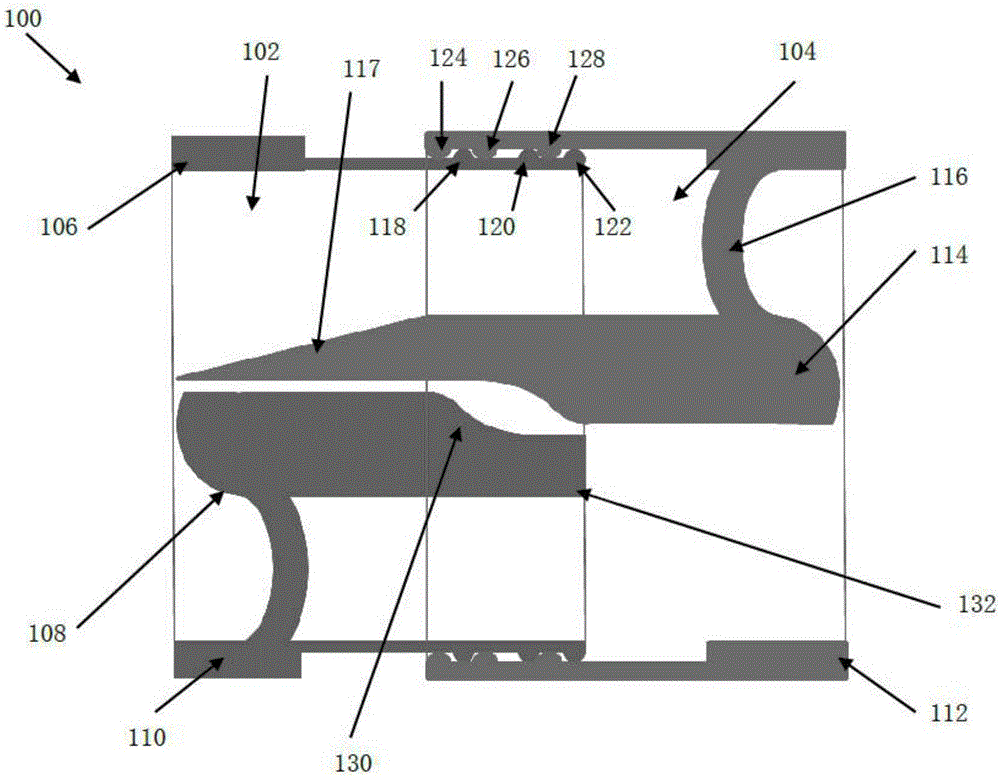

[0079] figure 1 A cross-sectional view of a rupture system 100 including a first tube 102 and a second tube 104 is shown. The first tube includes a hollow cylindrical portion 106 having a substantially circular cross-sectional shape and a guide member 108 elastically coupled to the hollow portion 106 by an elastic member 110 . The second tube 104 includes a hollow cylindrical portion 112 having a substantially circular cross-sectional shape and a rupture member 114 elastically coupled to the hollow portion 112 by an elastic member 116 . The rupture member includes a rupture portion 117 . The first tube 102 also includes elastic protrusions 118 , 120 and 122 , and the second tube 104 also includes elastic protrusions 124 , 126 and 128 .

[0080] Such as figure 1 As shown, the first tube 102 is configured to slide partially within the second tube 104 such that they are in operative engagement as described in detail below. The first tube and the second tube are configured to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com