Packaging box

A packaging box and box body technology, applied in the directions of packaging, transportation and packaging, containers, etc., can solve the problems of inability to open the cover and press the finger hook holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

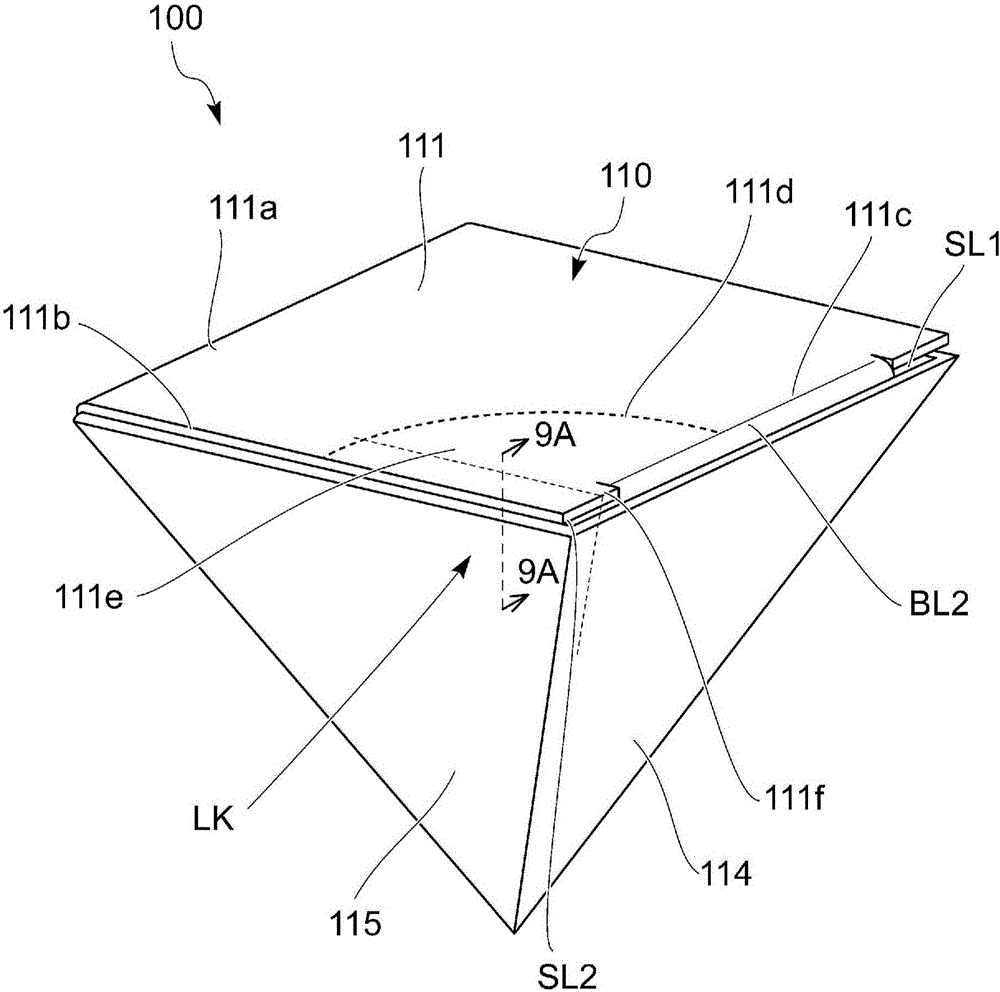

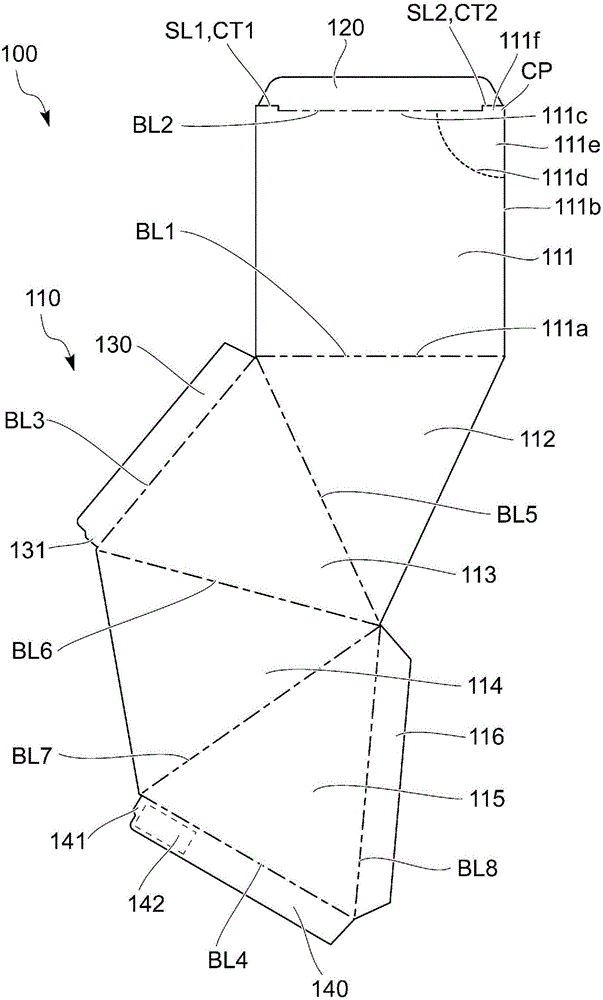

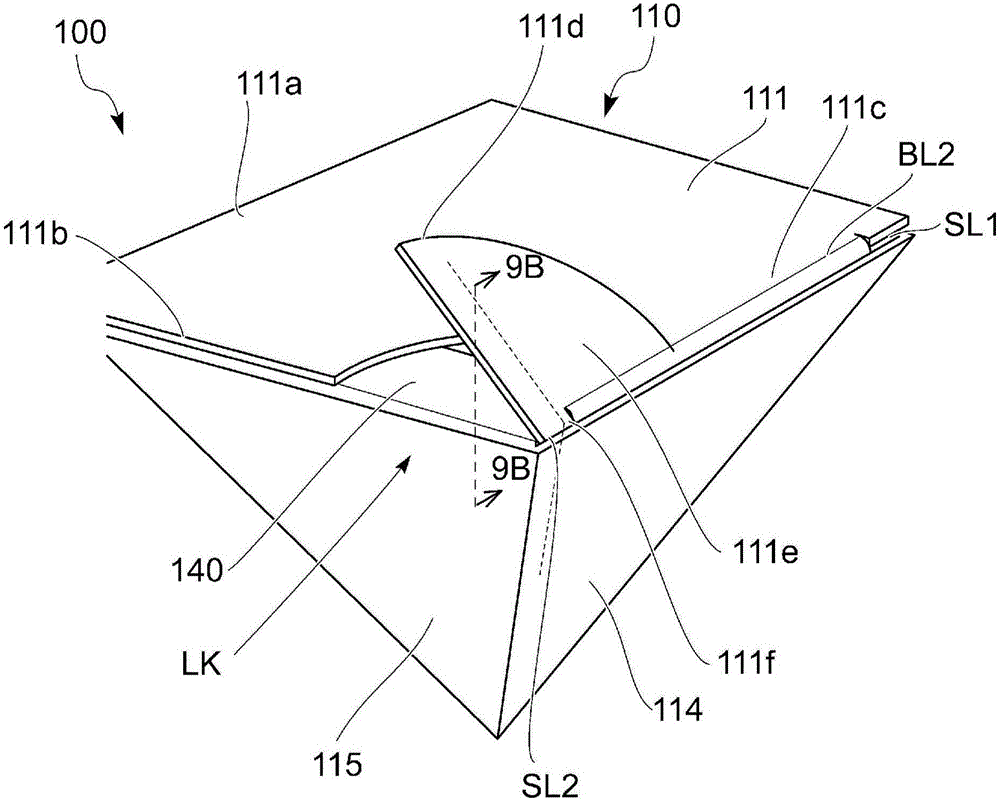

[0092] Below, according to figure 1 The packaging box 100 according to the first embodiment of the present invention will be described through FIG. 9 .

[0093] in, figure 1 It is a front perspective view showing the outline of the packaging box 100 according to Embodiment 1 of the present invention, figure 2 It is an expanded view of the packaging box 100 of Embodiment 1 of the present invention, Figure 3A , Figure 4A , Figure 5A , Figure 6A and Figure 7A It is a front perspective view showing the operation of the slot lock release handle piece 111e of the present invention, Figure 3B , Figure 4B , Figure 5B , Figure 6B and Figure 7B for corresponding to Figure 3A , Figure 4A , Figure 5A , Figure 6A and Figure 7A The rear perspective view of Figure 8 It is a front perspective view showing the open state of the opening and closing cover 111 of the packaging box 100 of the present invention, Figure 9A for along figure 1 A side sectional view ...

Embodiment 2

[0178] Next, according to Figure 10 and Figure 11 The packaging box 200 according to the second embodiment of the present invention will be described.

[0179] here, Figure 10 It is a perspective view showing an outline of a packaging box 200 according to Embodiment 2 of the present invention, Figure 11 It is an expanded view of the packing box 200 according to the second embodiment of the present invention.

[0180] The packaging box 200 of embodiment 2 has changed the number and shape of the polyhedron faces of the packaging box 100 of embodiment 1, and changed the number of opening and closing covers 111, and most elements are common to the packaging box 100 of embodiment 1, Therefore, detailed descriptions of common items are omitted, and only the reference numerals of numbers between 200 and 299 in the last two digits are added.

[0181] Such as Figure 10 and Figure 11 As shown, the packing box 200 of Embodiment 2 of the present invention is made of thick coat...

Embodiment 3

[0188] Next, according to Figure 12 and Figure 13 The packaging box 300 according to the third embodiment of the present invention will be described.

[0189] in, Figure 12 It is a perspective view showing an outline of a packaging box 300 according to Embodiment 3 of the present invention, Figure 13 It is an expanded view of the packaging box 300 according to the third embodiment of the present invention.

[0190] In the packaging box 300 of the third embodiment, a part of the polyhedron surface of the packaging box 100 of the second embodiment is changed into a curved surface, and most of the elements are common to the packaging box 100 of the second embodiment, so the detailed description of common matters is omitted. Only the reference numbers for numbers between 300 and 399 with the last two digits in common are appended.

[0191] Such as Figure 12 and Figure 13 As shown, the packaging box 300 of Embodiment 3 of the present invention is made of thick coated ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com