Automatic cooling ring main unit

A technology for automatic cooling and ring network cabinets, applied in the field of ring network cabinets, can solve problems such as poor results, and achieve the effect of providing convenience, good heat dissipation, and preventing electrical appliances from burning out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

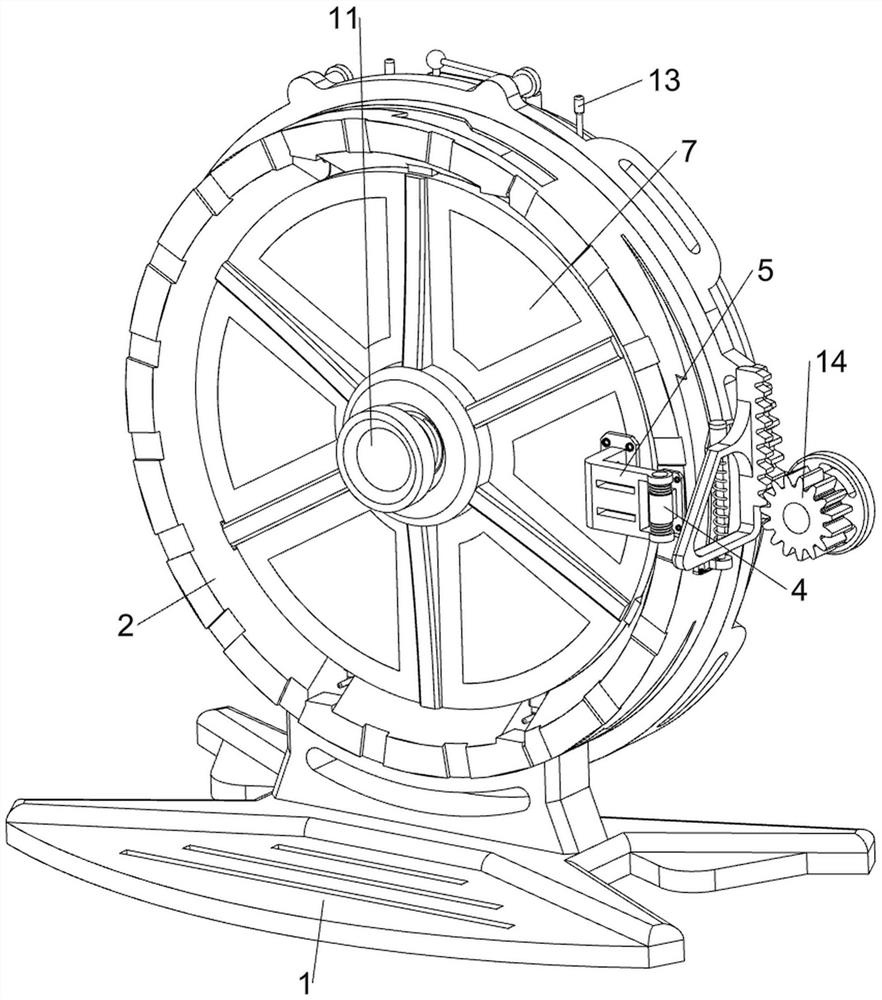

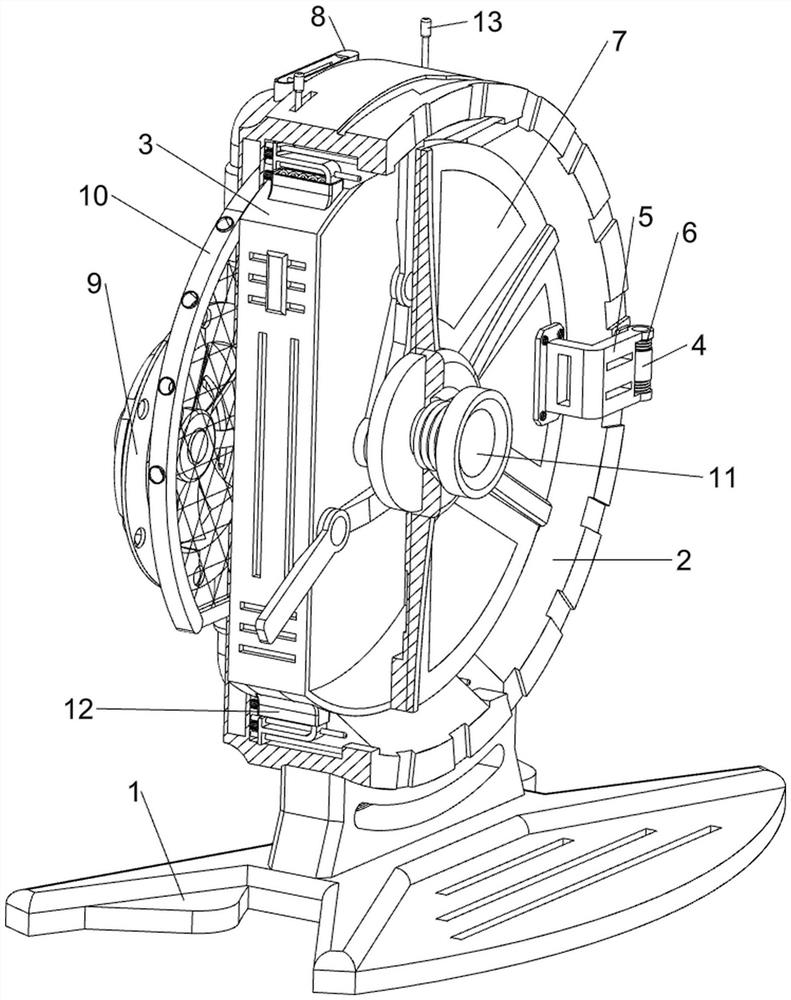

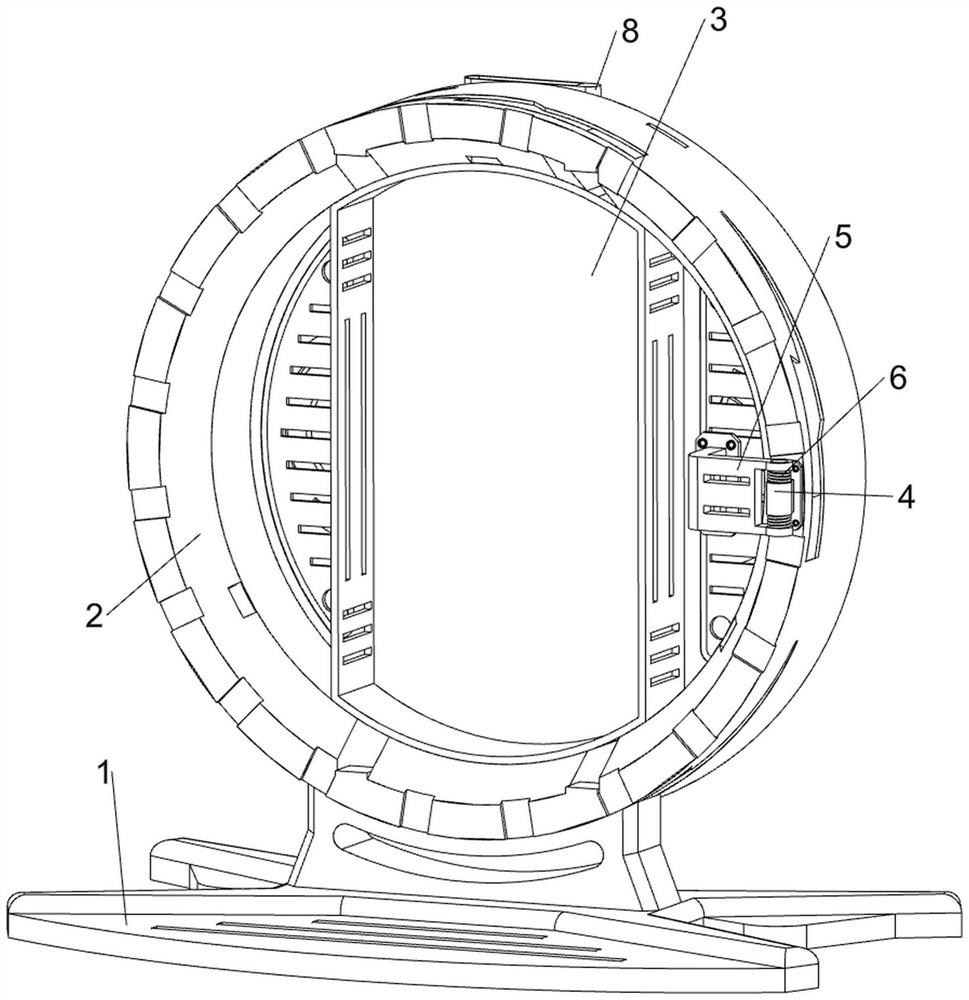

[0039] An automatic cooling ring network cabinet, in Figure 1-3 As shown in , it includes a support frame 1, a protective box 2, an installation cabinet 3, a first connecting block 4, a second connecting block 5, a torsion spring 6, a protective plate 7, a water adding bucket 8, a cooling mechanism 9, and a liquid cooling mechanism 10 And the clamping mechanism 11, the top of the support frame 1 is connected with the protective box 2 by screw connection, the protective box 2 is circular, and the right side of the front wall of the protective box 2 is connected with the first connecting block 4 by screw connection, the first The connecting block 4 is rotatably provided with a second connecting block 5, and a torsion spring 6 is connected between the upper and lower sides of the second connecting block 5 and the first connecting block 4, and the rear side of the left part of the second connecting block 5 is welded for protection. The protective plate 7, the protective plate 7 c...

Embodiment 2

[0045] On the basis of Example 1, in figure 2 , Figure 10 and Figure 11 As shown in , it also includes an ejection mechanism 12 that can automatically eject the installation cabinet 3 to the front side. The ejection mechanism 12 includes a third connecting block 120, a limit rod 121, a slider 122, a compression spring 123, and a tension spring 124. and guide rod 125, the upper and lower side walls of the installation cabinet 3 are symmetrically connected with the third connecting block 120 by means of bolt connection, and the four third connecting blocks 120 are slidingly provided with the installation cabinet 3 to slide forward more. The long-distance slide block 122, the four slide blocks 122 and the third connecting block 120 on the same side are all connected with tension springs 124, and the upper and lower sides of the inner rear side of the protective box 2 are symmetrically provided with guiding guides for guiding. Rod 125, four slide blocks 122 are all slidably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com