State detection sensor

一种状态检测、传感器的技术,应用在状态检测传感器领域,能够解决温度变化影响、异常判定、外部空气无法准确地检测温度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

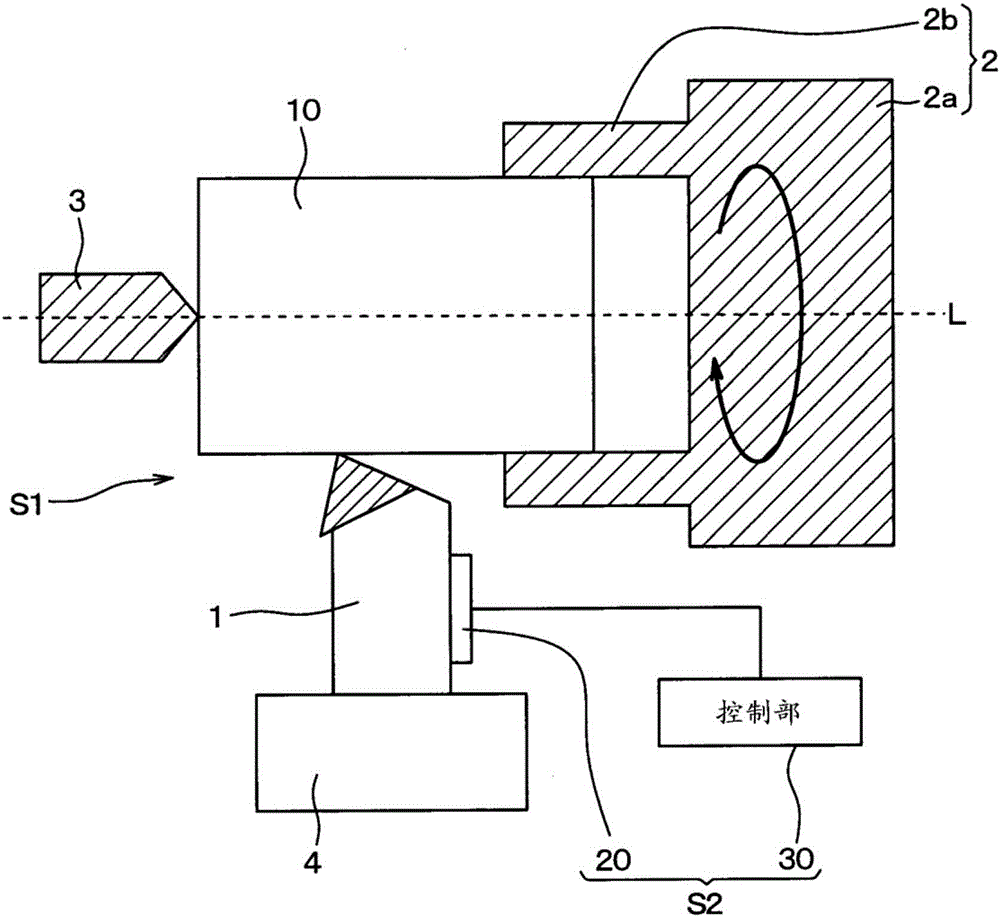

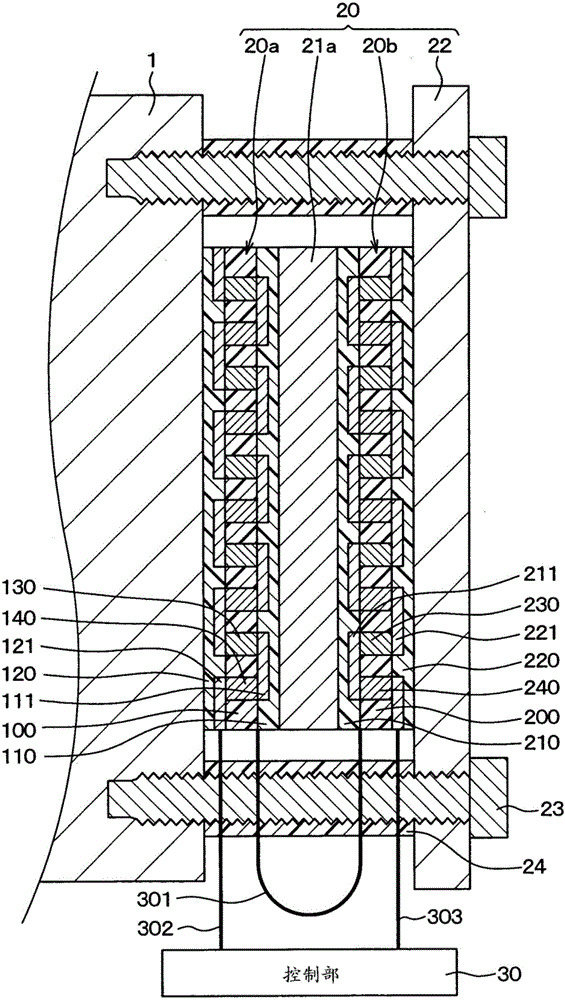

[0030] A first embodiment of the present disclosure will be described with reference to the drawings. In addition, in this embodiment, an example of an abnormality determination device that determines abnormal heat generation (state) of a cutting device using the state detection sensor of the present disclosure will be described.

[0031] Such as figure 1 As shown, the cutting device S1 has a cutter part and a pair of first and second clamps 2 and 3 . In the present embodiment, the cutter part 1 is fixed to the support member 4 . In addition, the first jig 2 is configured to have a main body portion 2a and three holding portions 2b protruding in the same direction from the main body portion 2a (in figure 1 Only two are shown in the figure), and the workpiece 10 is sandwiched by the three holding parts 2b. The second jig 3 is arranged on the side of the workpiece 10 opposite to the side held by the first jig 2 so as to fix the workpiece 10 together with the first jig 2 . ...

no. 2 approach

[0090] A second embodiment of the present disclosure will be described. In this embodiment, the heat receiving body is arranged on the opposite side to the thermal buffer body 21a via the first heat flux sensor 20a with respect to the first embodiment, and the rest is the same as that of the first embodiment, so description thereof will be omitted here.

[0091] In this embodiment, if Figure 9 As shown, the state detection sensor 20 is equipped with the heat receiver 25 arrange|positioned on the side opposite to the heat buffer body 21a across the 1st heat flux sensor 20a. That is, the state detection sensor 20 is equipped with the heat receiver 25 arrange|positioned between the cutter part 1 and the 1st heat flux sensor 20a. The heat receiving body 25 is formed of a member having a predetermined heat capacity (thermal resistance) in the same manner as the heat buffer body 21a and the radiator 22, and has a flat plate shape, and is made of metal such as Cu and Al, resin, or ...

no. 3 approach

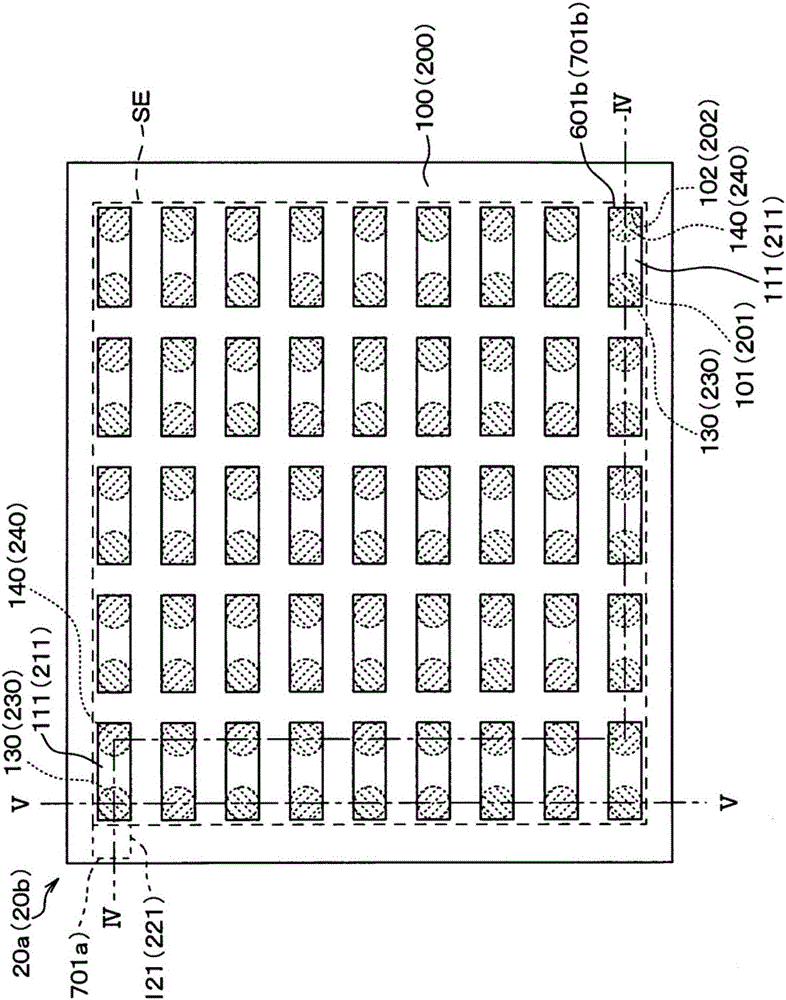

[0095] A third embodiment of the present disclosure will be described. Compared with the first embodiment, this embodiment further includes a plurality of heat flux sensors and thermal buffers, and the rest is the same as that of the first embodiment, so description thereof will be omitted here.

[0096] In this embodiment, if Figure 10 As shown, for the state detection sensor 20, in addition to the first and second heat flux sensors 20a, 20b and the thermal buffer 21a, the third and fourth heat flux sensors 20c, 20d and the thermal buffer 21b are also provided. , 21c. Moreover, the state detection sensor 20 is arranged from the side of the cutter part 1 according to the first heat flux sensor 20a, the thermal buffer 21a, the second heat flux sensor 20b, the thermal buffer 21b, the third heat flux sensor 20c, and the thermal buffer 21c. , the fourth heat flux sensor 20d and the radiator 22 are arranged in sequence.

[0097] The third and fourth heat flux sensors 20c and 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com