Method and apparatus for applying an imprint to a print carrier and inspecting it

A technology of imprinting and carrier, applied in printing, printing device, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

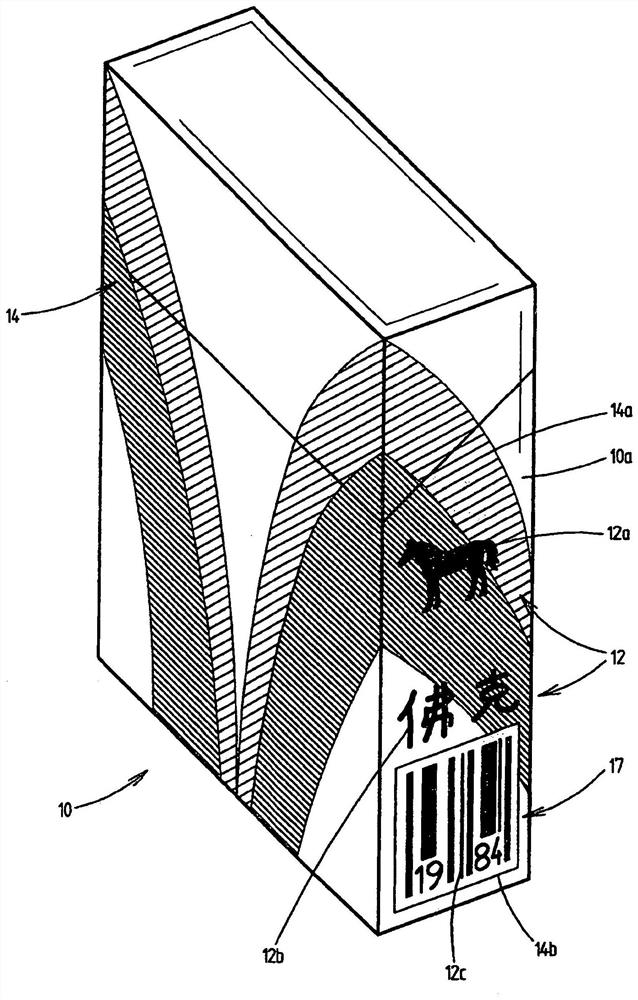

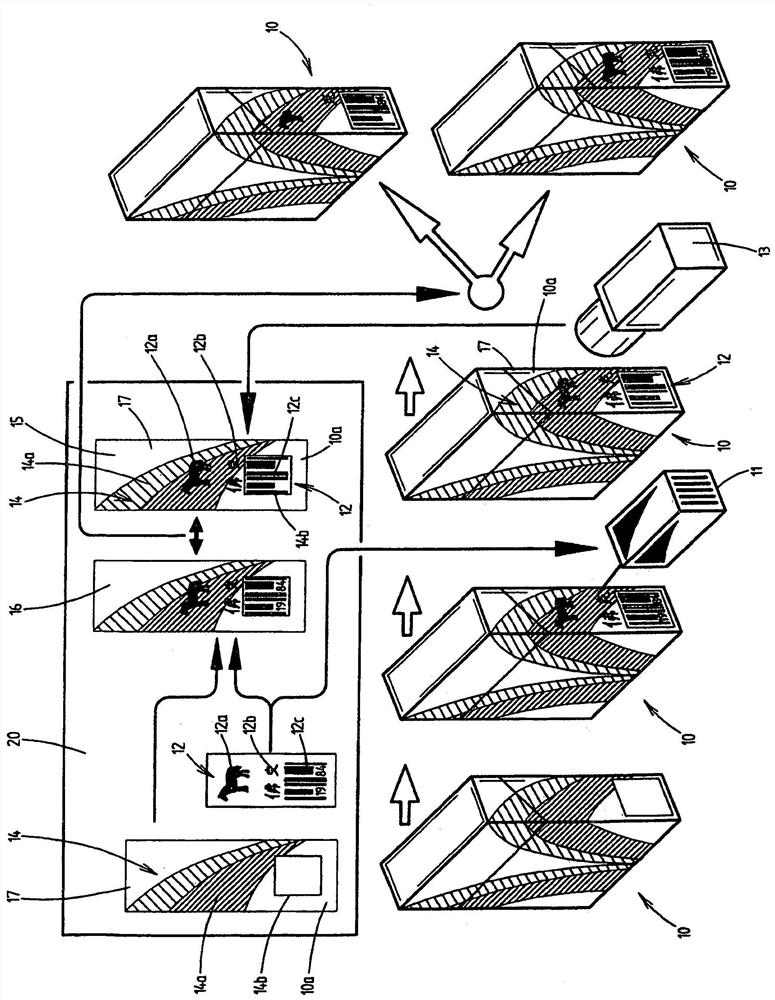

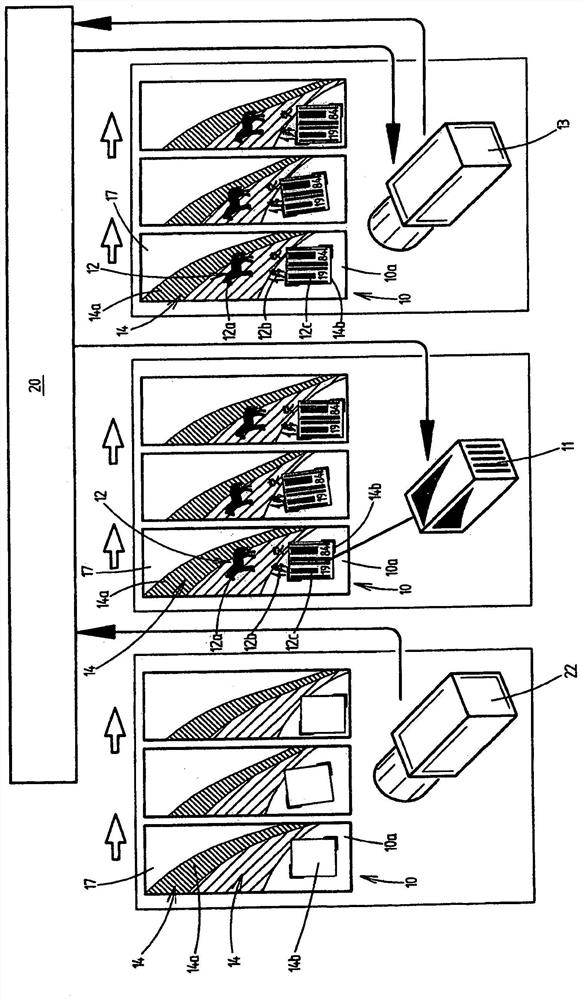

[0030] figure 1A standard cigarette pack 10 of the flip-top cigarette type is shown as an object for imprinting. The printing and checking method according to the invention is explained by way of example using the standard cigarette pack.

[0031] This printing and inspection method is used during the production process of the corresponding product, here the cigarette pack 10 . Of course, the present invention is not limited to such cigarette pack 10 printing. It can generally be used in conjunction with every type of equipment used to manufacture and / or pack cigarettes. In this case, it is independent neither of the type of machine used nor of the types of cigarettes or cigarette packs that can be produced.

[0032] It is often necessary to print the corresponding printing carrier during the production process, ie at a suitable point on the production line or on the corresponding packaging machine, and to also check the printing "inline" for errors. For this purpose, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com