Backlight device and liquid crystal display device provided with same

A backlight and light source technology, applied in the field of backlight devices, can solve problems such as high power consumption, complicated drive circuits, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

[0128]

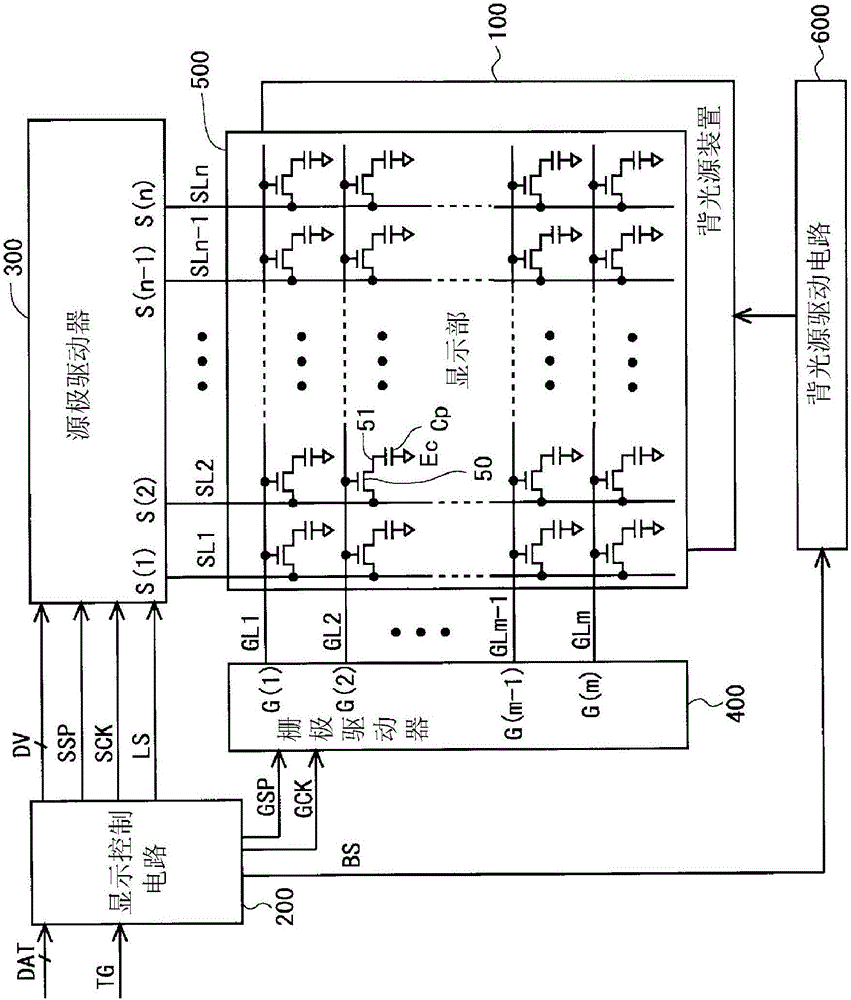

[0129] figure 2 It is a block diagram showing the overall configuration of a liquid crystal display device including the backlight unit according to the first embodiment of the present invention. The liquid crystal display device includes: a backlight device 100, a display control circuit 200, a source driver (video signal line driving circuit) 300, a gate driver (scanning signal line driving circuit) 400, a display unit 500, and a backlight driving circuit 600.

[0130] In the display unit 500, it includes: a plurality (n) of source bus lines (video signal lines) SL1˜SLn, a plurality (m) of gate bus lines (scanning signal lines) GL1˜GLm, and Intersections of the bus lines SL1 to SLn and the plurality of gate bus lines GL1 to GLm respectively correspond to a plurality (n×m) of pixel formation portions provided. These pixel forming portions are arranged in a matrix to form a pixel array. Each pixel forming portion includes: a thin film transistor (TFT) 50 as a swi...

no. 2 Embodiment approach >

[0158]

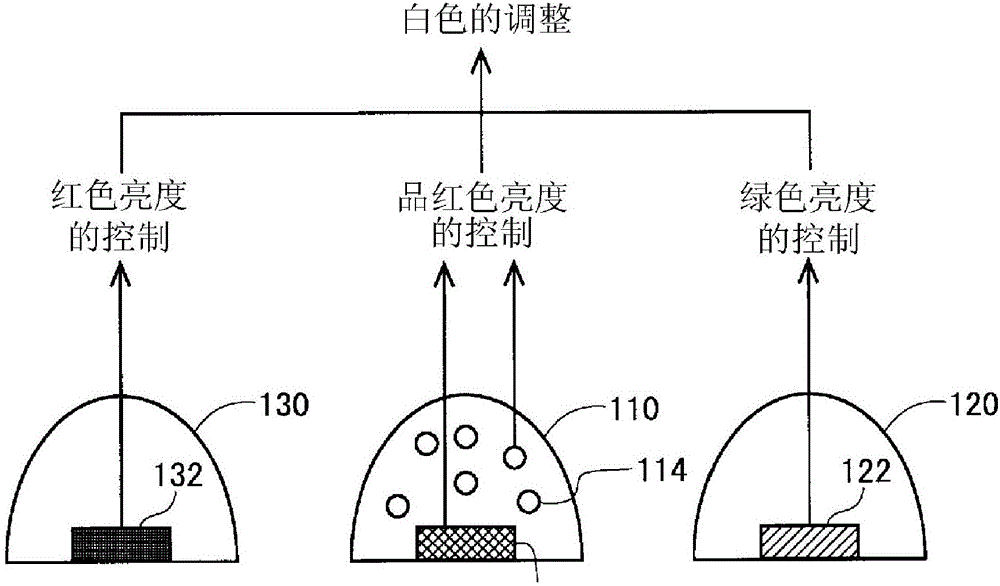

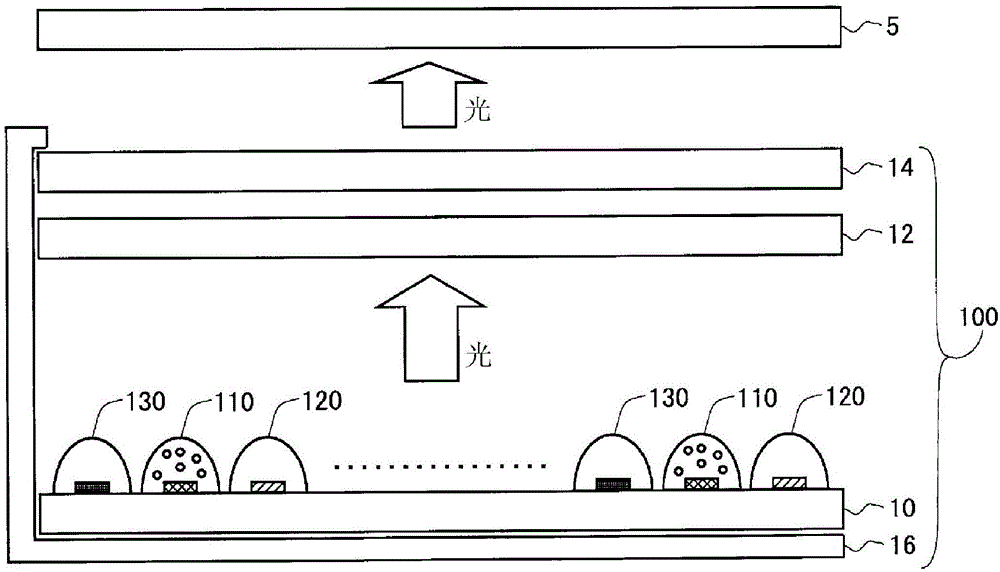

[0159] Overall composition (refer to figure 2 ) and the composition of the backlight unit 100 ( image 3 ) is the same as that of the above-mentioned first embodiment, and therefore description thereof will be omitted. However, about image 3 The configuration of the LED module mounted on the LED substrate 10 is different between the above-mentioned first embodiment and this embodiment. Figure 9 It is a figure which shows the structure of the LED module mounted on the LED board|substrate 10 in this embodiment. In this embodiment, the LED module includes: a magenta light emitter 110 in which a blue LED element 112 is covered with a red phosphor 114 , a green light emitter 120 including a green LED element 122 , and a blue light emitter including a blue LED element 142 . illuminant 140 . That is, the structure of the LED module of this embodiment is Figure 29 The configuration of the blue light emitting body 140 including the blue LED element 142 is added to t...

no. 3 Embodiment approach >

[0167]

[0168] Overall composition (refer to figure 2 ) and the composition of the backlight unit 100 ( image 3 ) is the same as that of the above-mentioned first embodiment, and therefore description thereof will be omitted. However, about image 3 The configuration of the LED module mounted on the LED substrate 10 is different between the above-mentioned first embodiment and this embodiment. Figure 12 It is a figure which shows the structure of the LED module mounted on the LED board|substrate 10 in this embodiment. In this embodiment, the LED module includes: a magenta light emitter 110 in which a blue LED element 112 is covered with a red phosphor 114 , a green light emitter 120 including a green LED element 122 , and a red light emitter including a red LED element 132 130 and a blue light emitter 140 comprising a blue LED element 142 . That is, the structure of the LED module of this embodiment is Figure 29 The structure of the red light emitter 130 including ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com