fluid flow valve

A flow-through valve and fluid technology, applied in the direction of charging system, machine/engine, engine control, etc., can solve the feasibility of restricting the use of actuators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

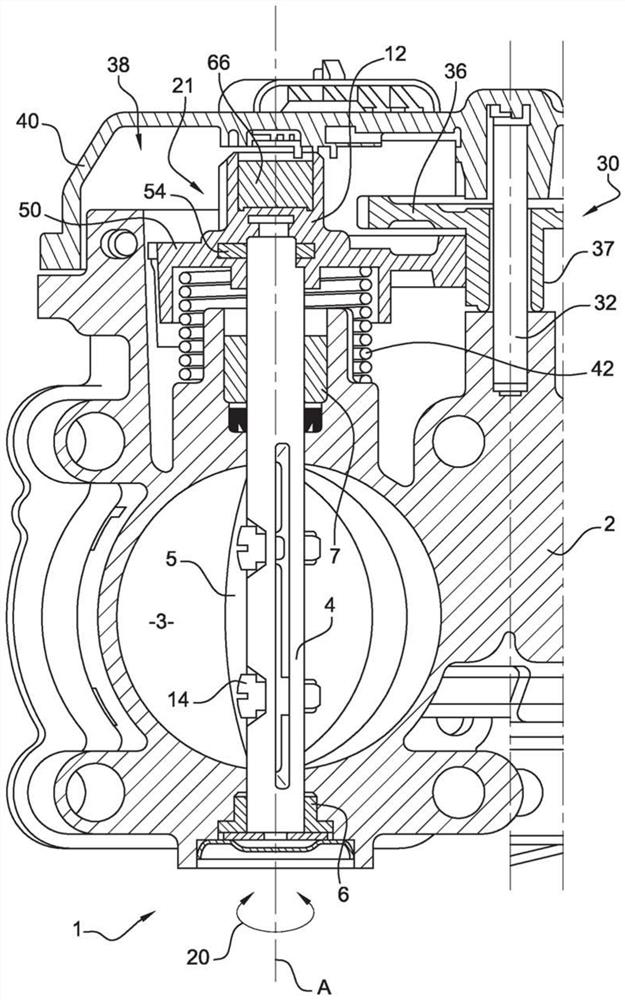

[0027] like figure 1 As shown, the invention relates to a fluid communication valve 1, in particular for use in motor vehicles. It is here a valve for regulating the intake air flow of a heat engine, in particular a metering valve for a diesel engine.

[0028] This valve is a valve known to those skilled in the art, for example as described in patent application FR2992046.

[0029] In particular, the valve comprises a body 2 inside which a conduit 3 for fluid communication is arranged. Here, the main body 2 is intended to be mounted on the intake line of the engine by means of a connection so that the part of the gas flowing into this branch passes through the line and is directed towards the engine to participate in combustion. Connections and intake lines are known per se and are not shown.

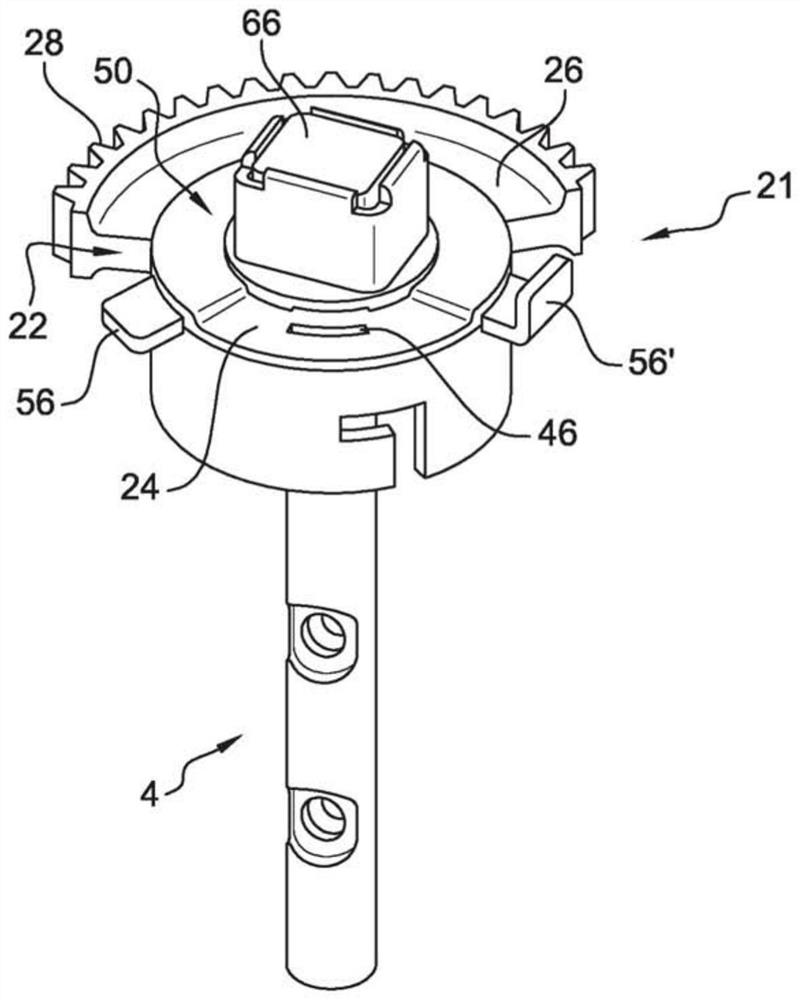

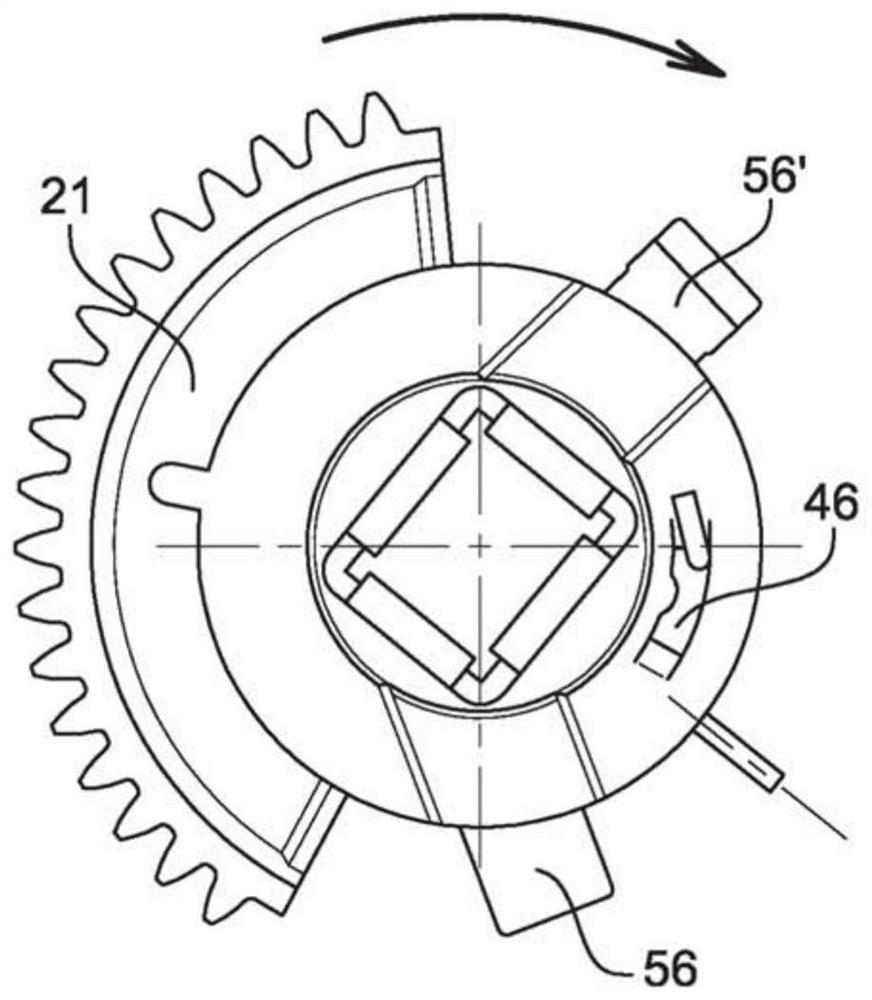

[0030] In the body 2 of the valve 1 is received a control shaft 4 which is free to rotate together with a valve 5 which is solidified as indicated by an arrow 20 which rotates about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com