Rotary machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

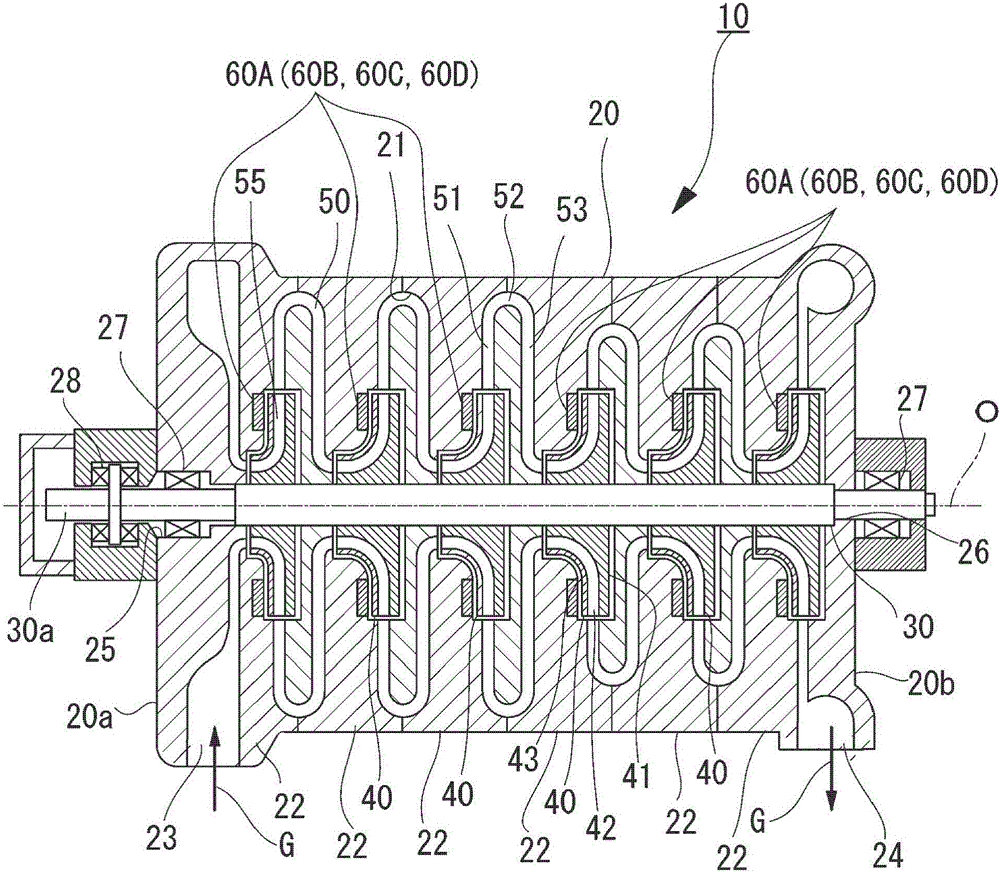

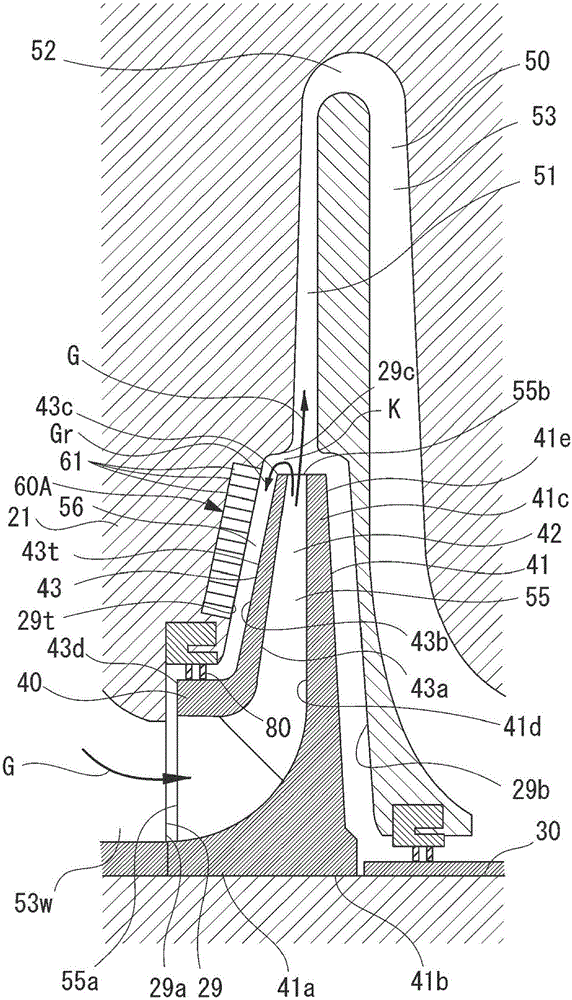

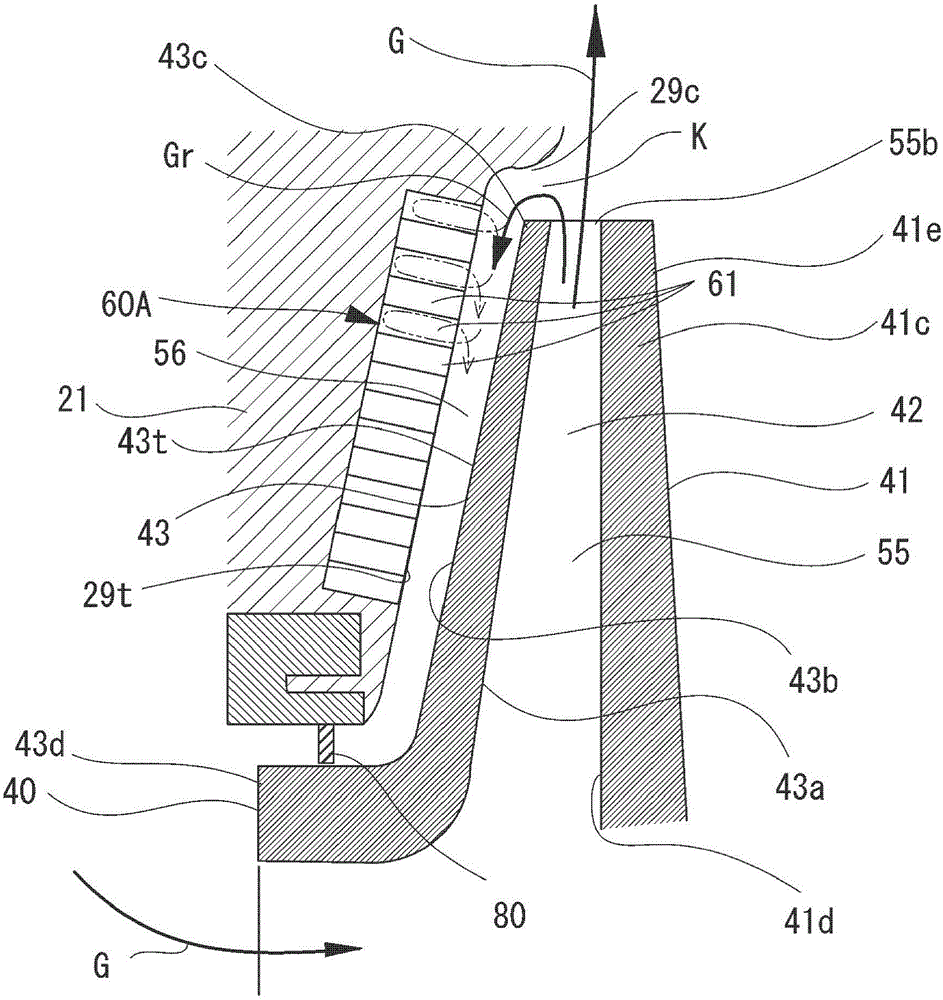

[0041] figure 1 It is a cross-sectional view showing the structure of a centrifugal compressor as an example of a rotating machine in the present embodiment. figure 2 It is an enlarged cross-sectional view showing the main part of the centrifugal compressor. image 3 It is a cross-sectional view showing a hole forming surface provided in a region of the casing facing the shroud portion of the impeller. Figure 4 It is a figure which shows the some hole formed in the hole formation surface.

[0042] like figure 1 As shown, the centrifugal compressor (rotary machine) 10 which is a rotating machine of the present embodiment mainly includes a casing 20 , a rotating shaft 30 , and an impeller 40 . The rotation shaft 30 is rotatably supported around the central axis O in the casing 20 . The impeller 40 is attached to the rotating shaft 30, and compresses the gas G that is the working fluid by centrifugal force.

[0043] The housing 20 has a structure in which a plurality of an...

no. 2 approach

[0074] Next, a second embodiment of the centrifugal compressor as an example of the rotary machine of the present invention will be described. In the second embodiment described below, since only the structure of the hole forming surface is different from that of the first embodiment, the same parts as those in the first embodiment will be described with the same reference numerals, and repeated descriptions will be omitted.

[0075] Figure 5 It is an enlarged cross-sectional view showing a main part of the centrifugal compressor in the second embodiment of the above-described rotating machine. Image 6 It is a figure which shows the some hole formed in the hole formation surface.

[0076] like Figure 5 As shown, the centrifugal compressor 10 in this embodiment includes a casing 20 , a rotating shaft 30 , and an impeller 40 .

[0077] In the centrifugal compressor 10 , a hole forming surface 60B is formed in the recessed portion 29 a formed in the impeller accommodating p...

no. 3 approach

[0086] Next, a third embodiment of the centrifugal compressor as an example of the rotary machine of the present invention will be described. In the third embodiment described below, since only the structure of the hole forming surface is different from that of the first embodiment, the same parts as those of the first embodiment are denoted by the same reference numerals, and repeated descriptions are omitted.

[0087] Figure 7 It is a cross-sectional view showing an example of the hole formed in the hole forming surface in the centrifugal compressor in the third embodiment of the rotary machine.

[0088] The centrifugal compressor 10 in this embodiment is the same as figure 1 , figure 2 The above-described first embodiment shown is provided with a casing 20 , a rotating shaft 30 , and an impeller 40 in the same manner.

[0089] In the centrifugal compressor 10 , a hole forming surface 60C is formed in the recessed portion 29 a formed in the impeller housing portion 29 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com