Percussion releasing device used for axial powder actuated tool

A technology of releasing device and nailer, which is applied in nailing tools, manufacturing tools and other directions, can solve the problems of poor processing accuracy, high manufacturing cost and high roughness, and achieve the effect of reducing the difficulty of processing and assembly and reducing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

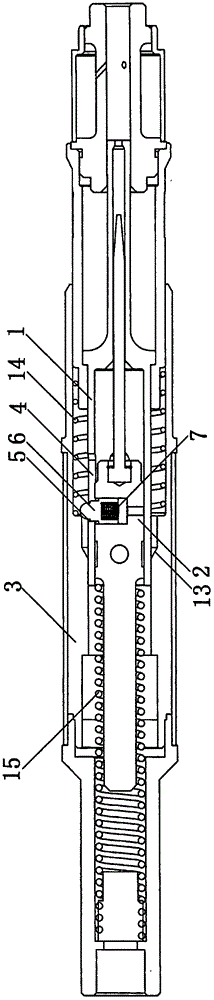

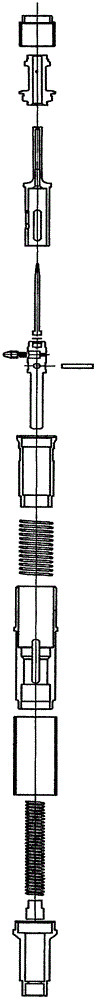

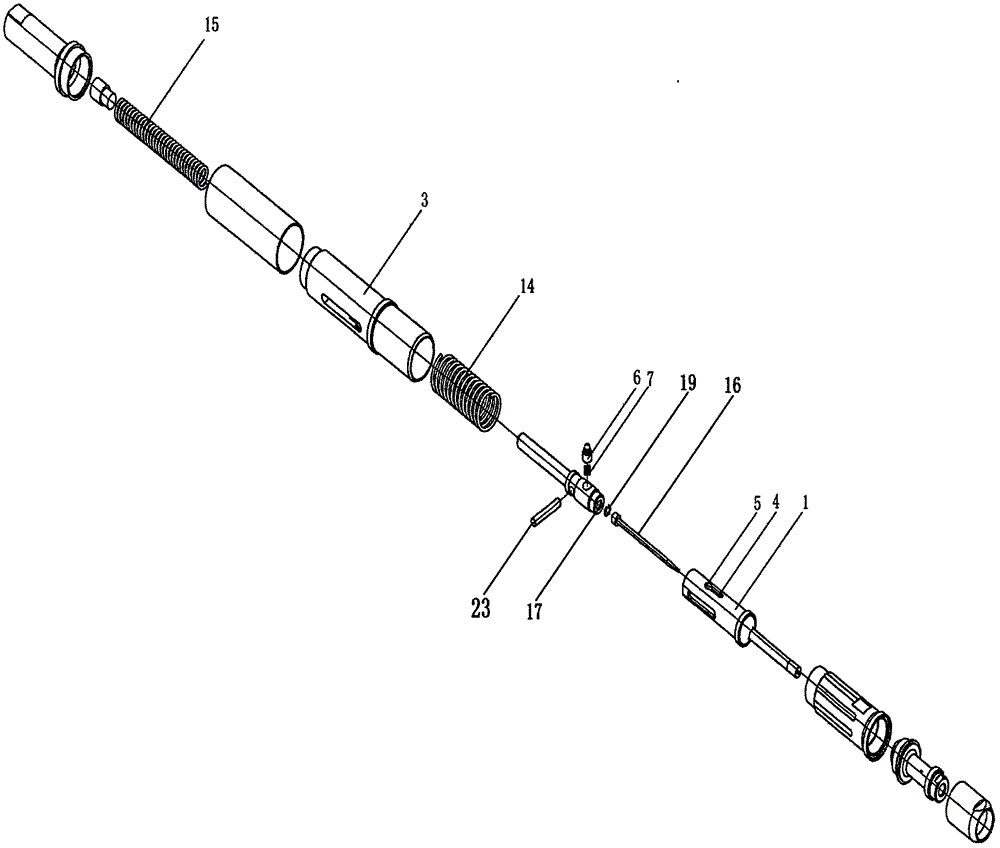

[0041] The front end of the nail shooter is pressed against the substrate and compressed, and the firing sleeve 1 moves backward in the main sleeve 3 . At this time, the brake pin 6 is located in the through hole 5 and moves accordingly, and its detail 10 drives the hammer 2 to move backward at the same time (such as Figure 6 shown). During the aforementioned movement, the firing spring 15 is compressed by the hammer 2 .

[0042] When moving to the set position, the firing surface 13 inside the main sleeve 3 will contact the top spherical surface of the detail 10, so that the braking pin 6 is compressed downward as a whole.

[0043] When the upper step 11 is located on the inner circumference of the main sleeve 3, the detail 10 is located in the through hole 5 (through groove 4), and because the size of the detail 10 is small, at this time, the restraining effect of the brake pin 6 fails, and the strike The hammer 2 drives the brake pin 6 to move forward rapidly under the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com