Patents

Literature

39results about How to "In line with the development trend of miniaturization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wall-mounted air conditioner indoor unit

PendingCN108758830AImprove the air supply effectMeet different needsLighting and heating apparatusHeating and ventilation casings/coversImpellerEngineering

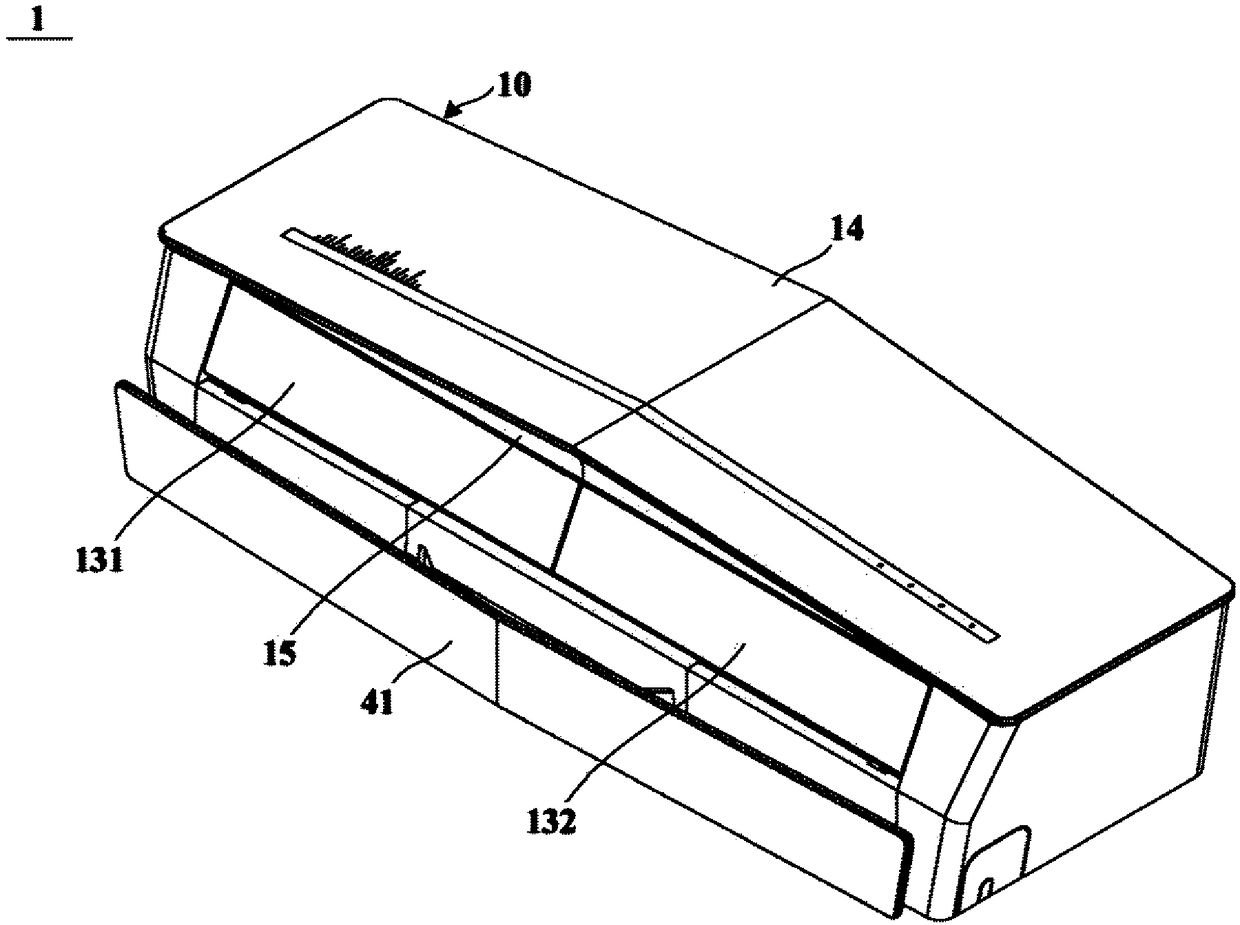

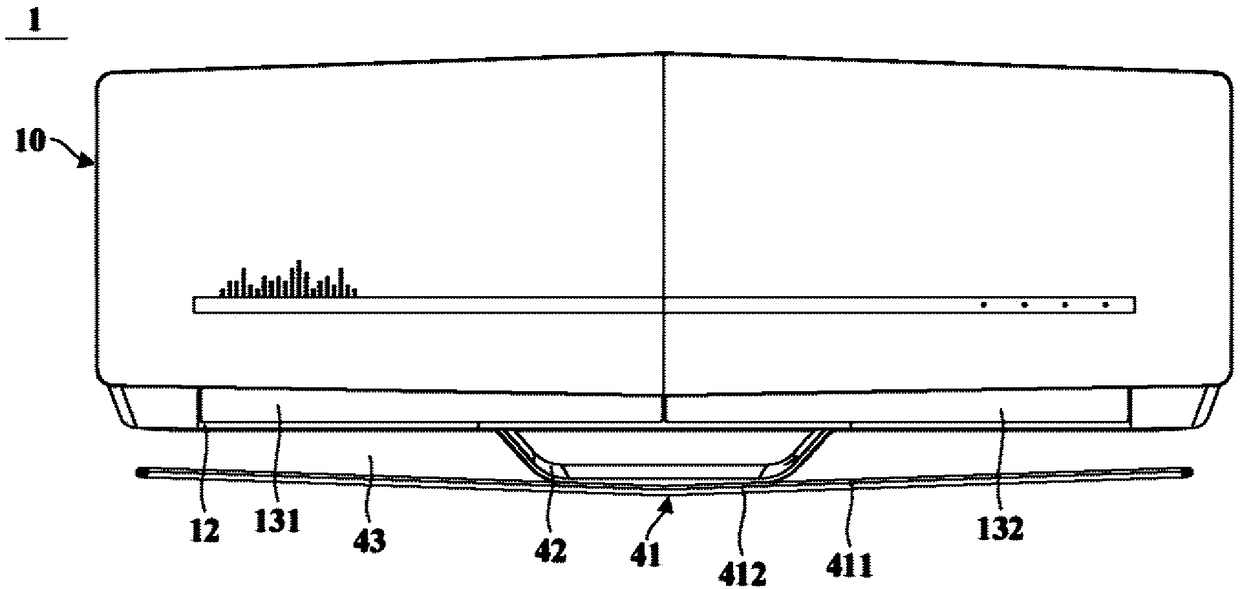

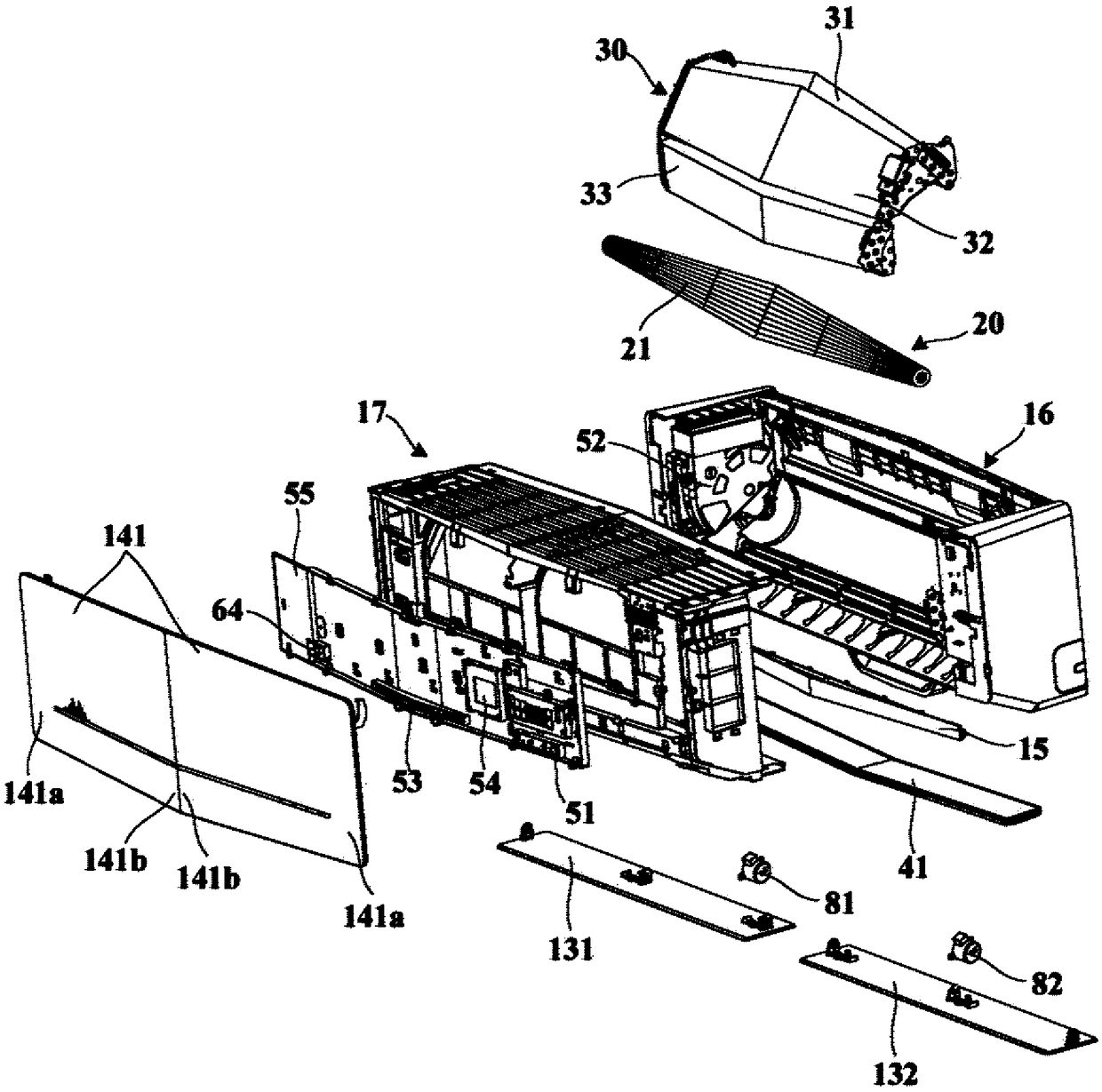

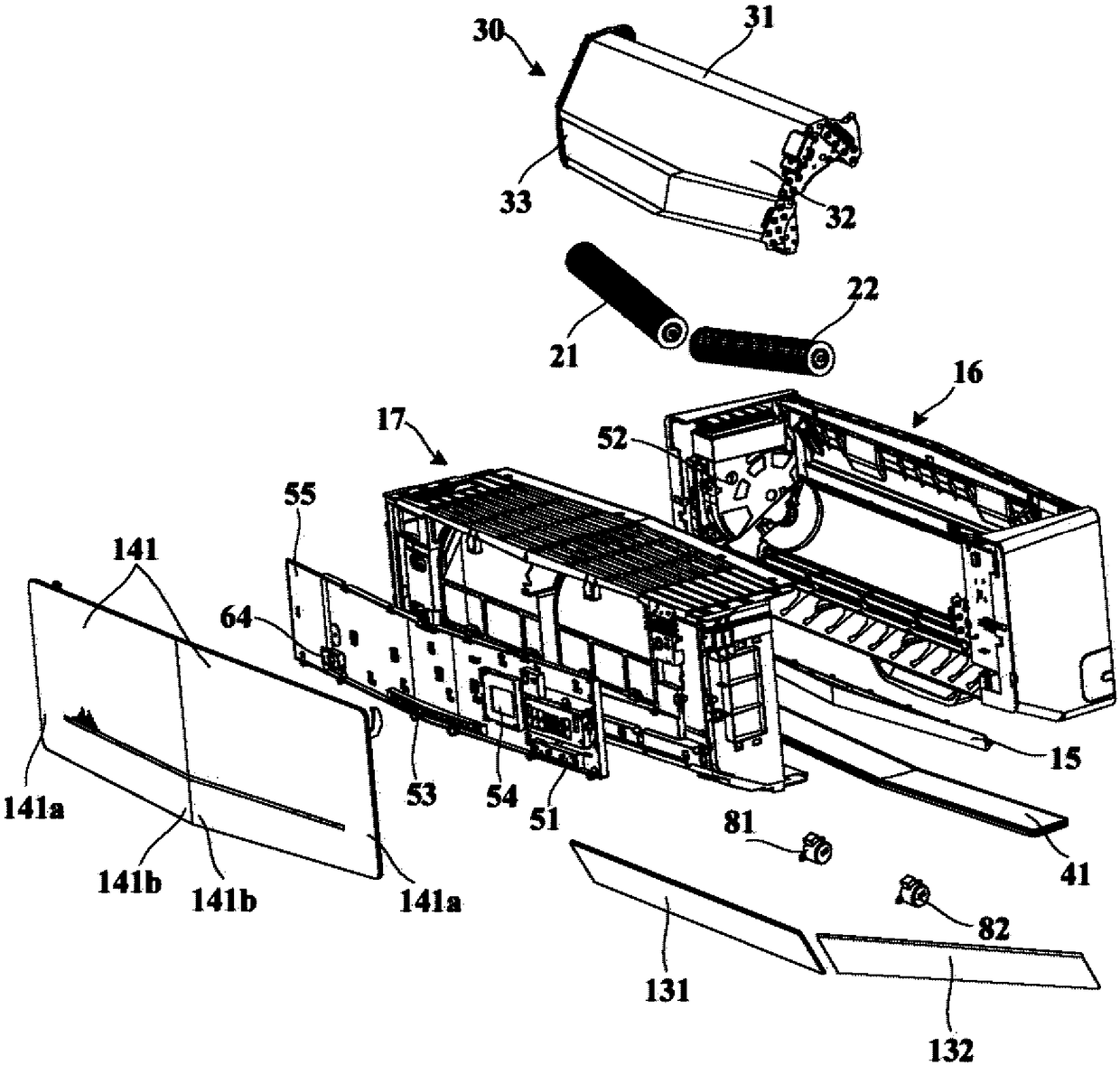

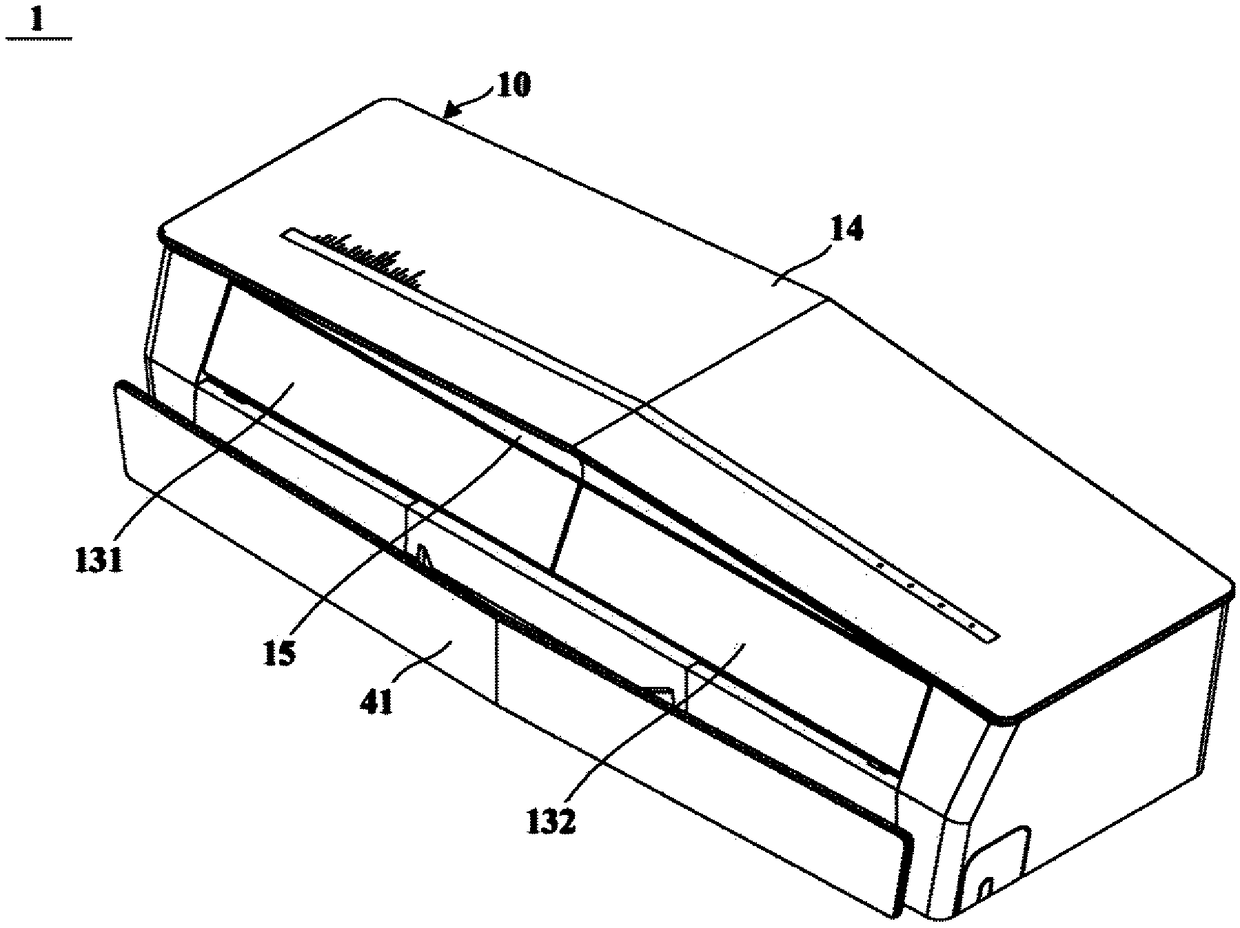

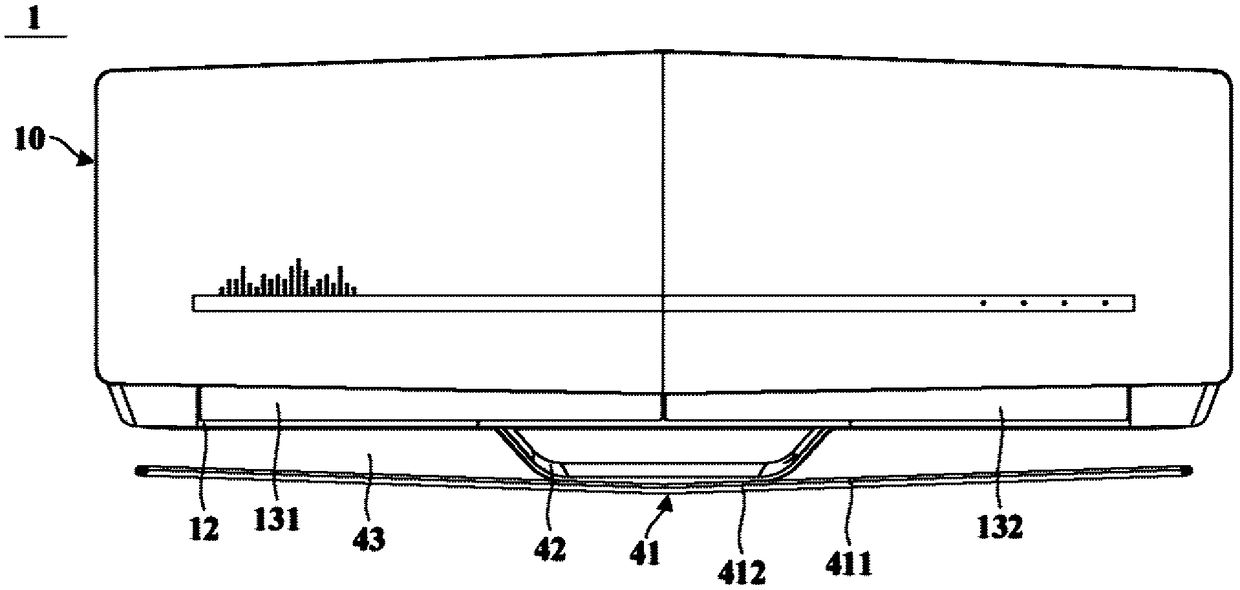

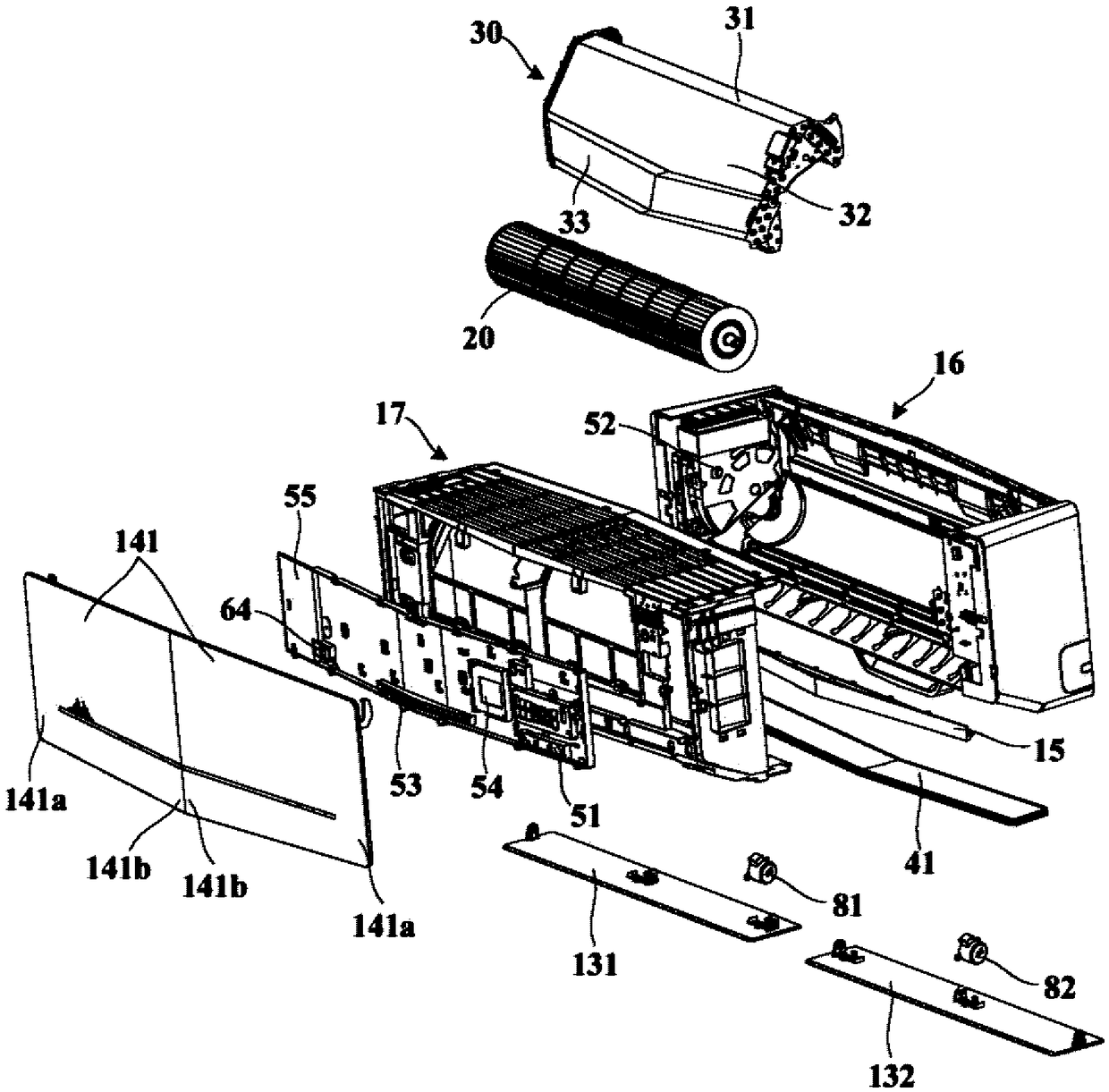

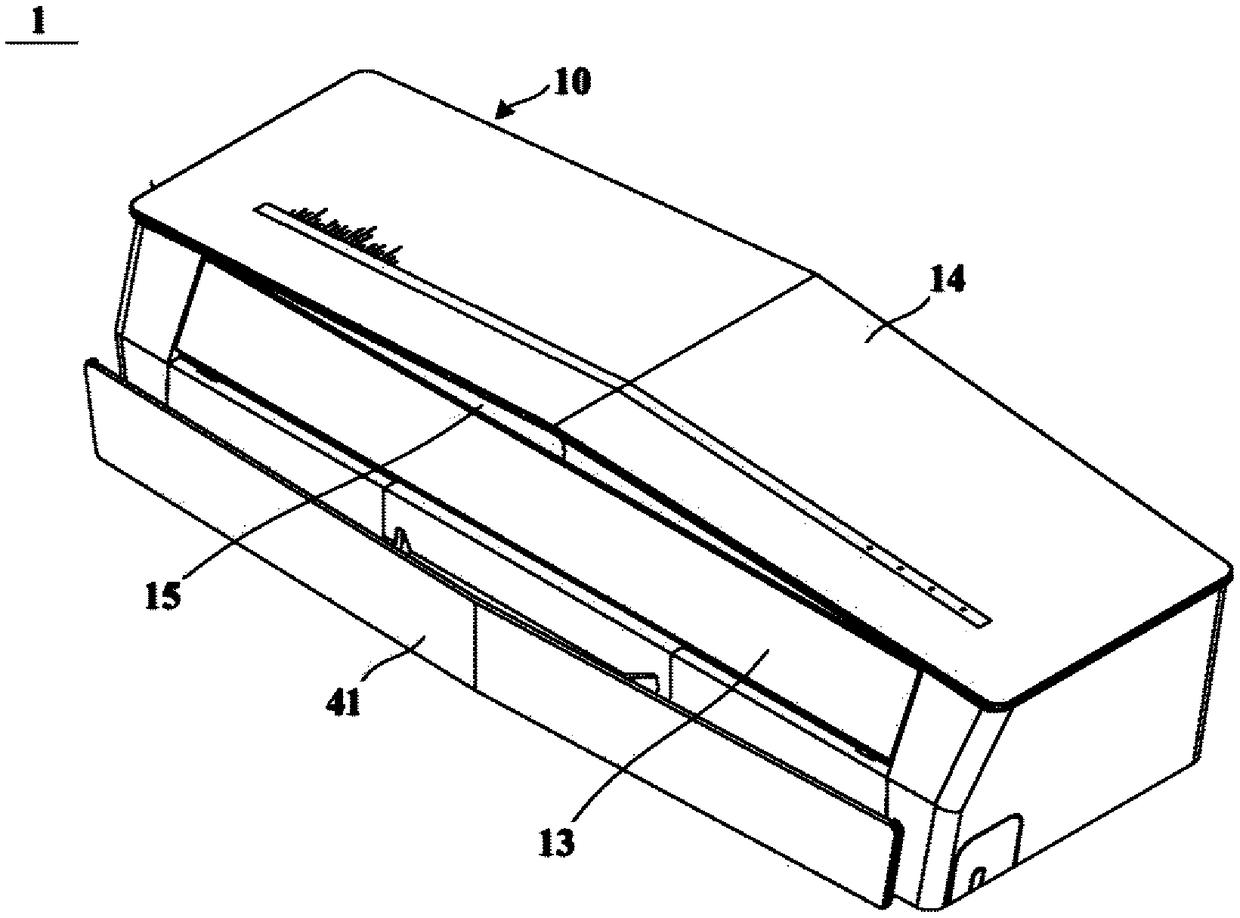

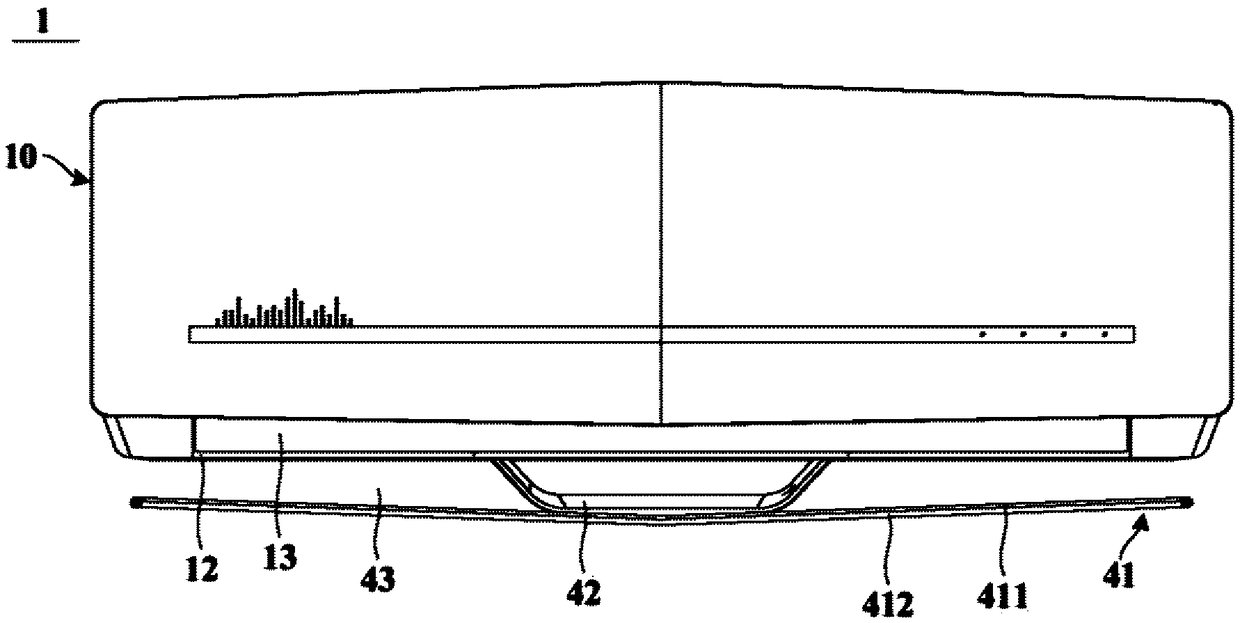

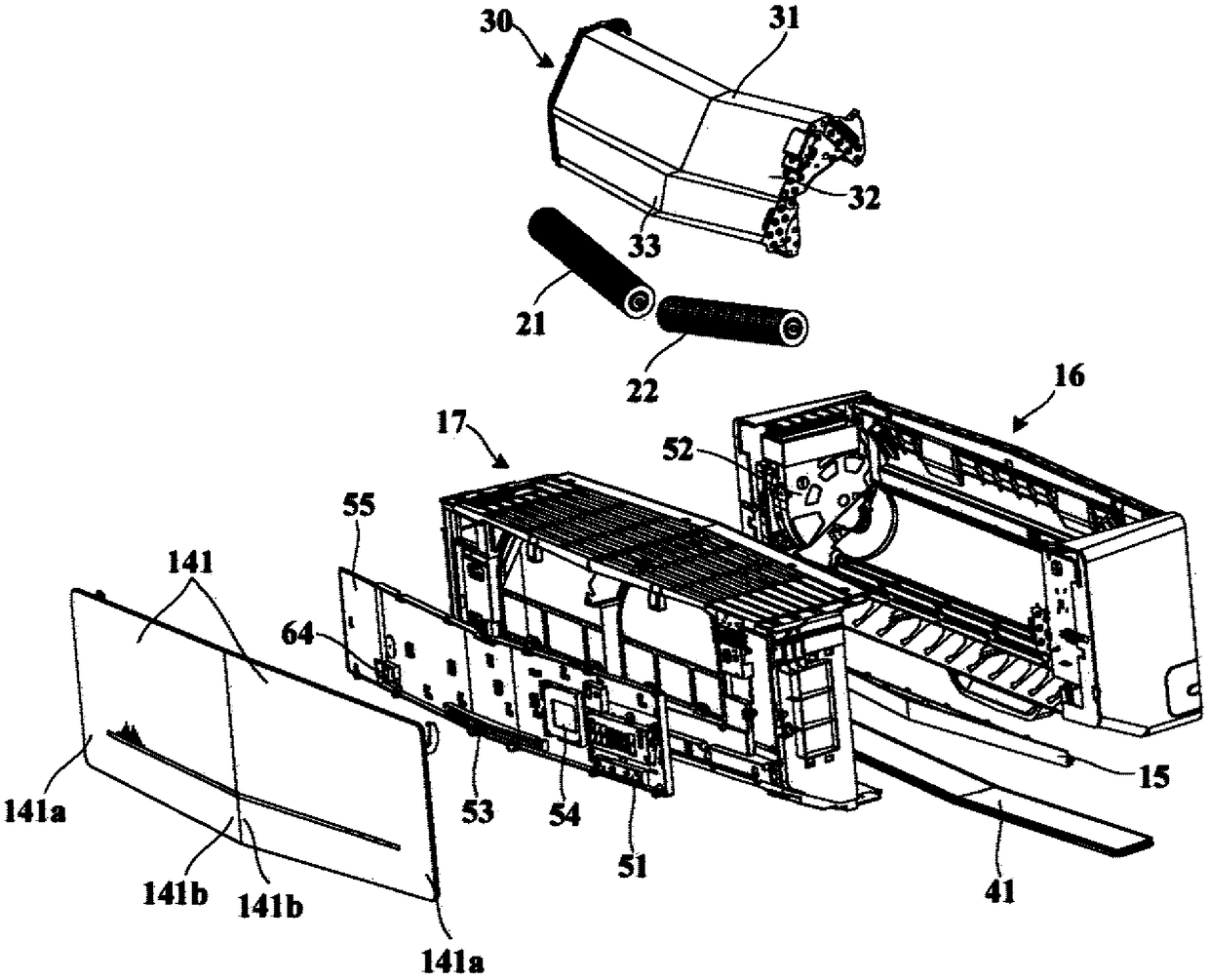

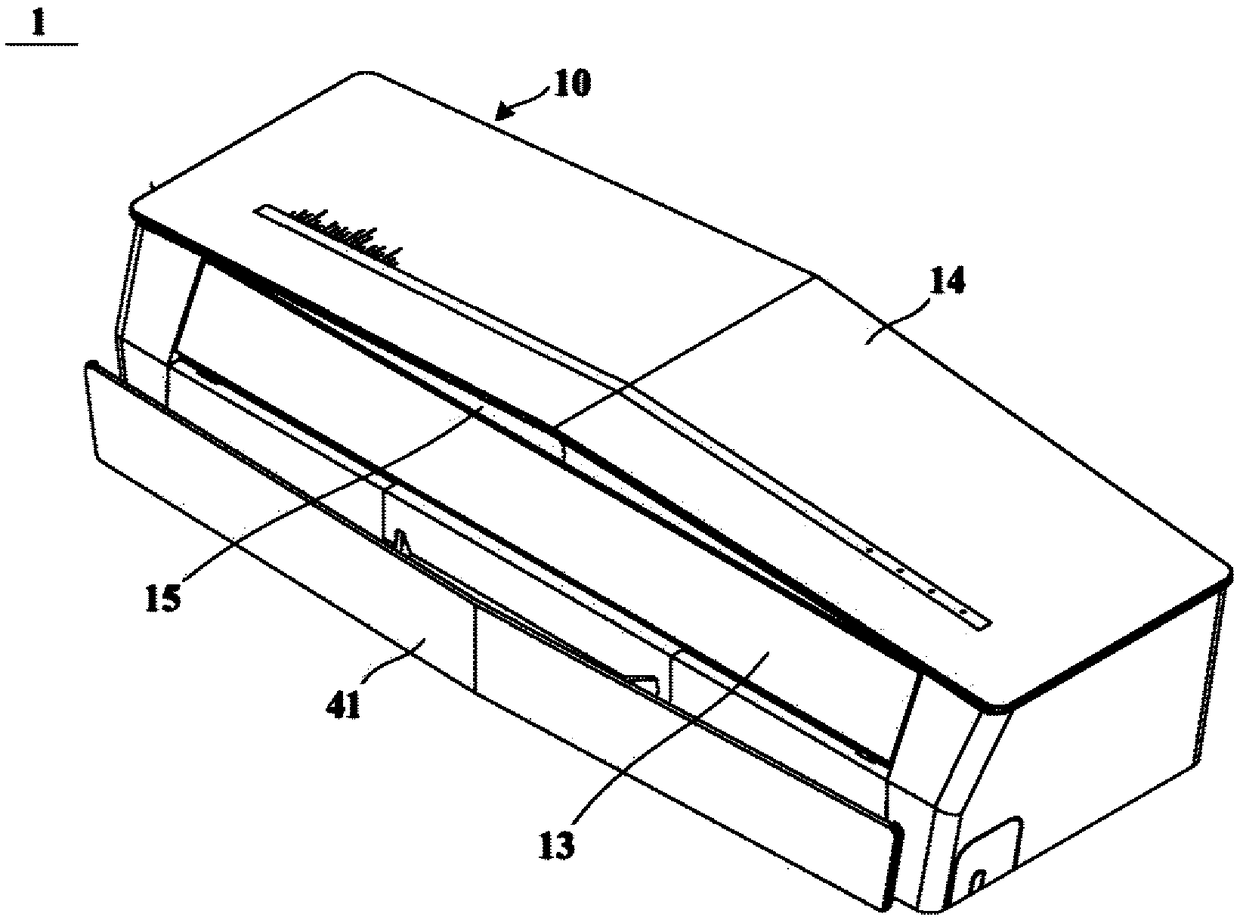

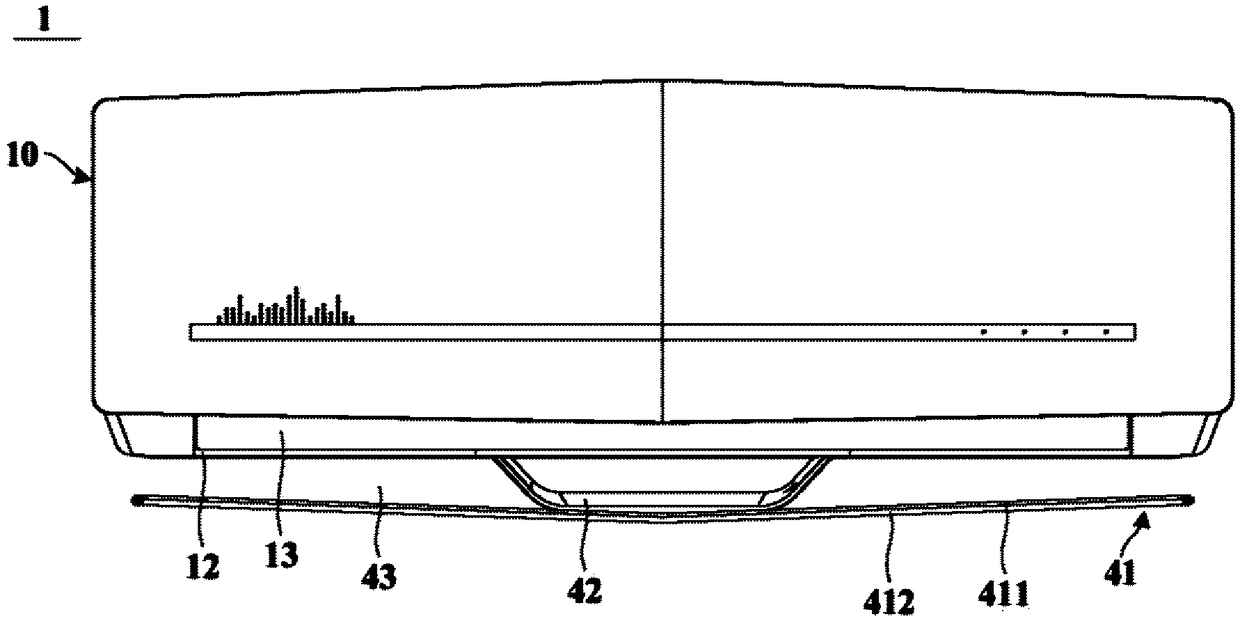

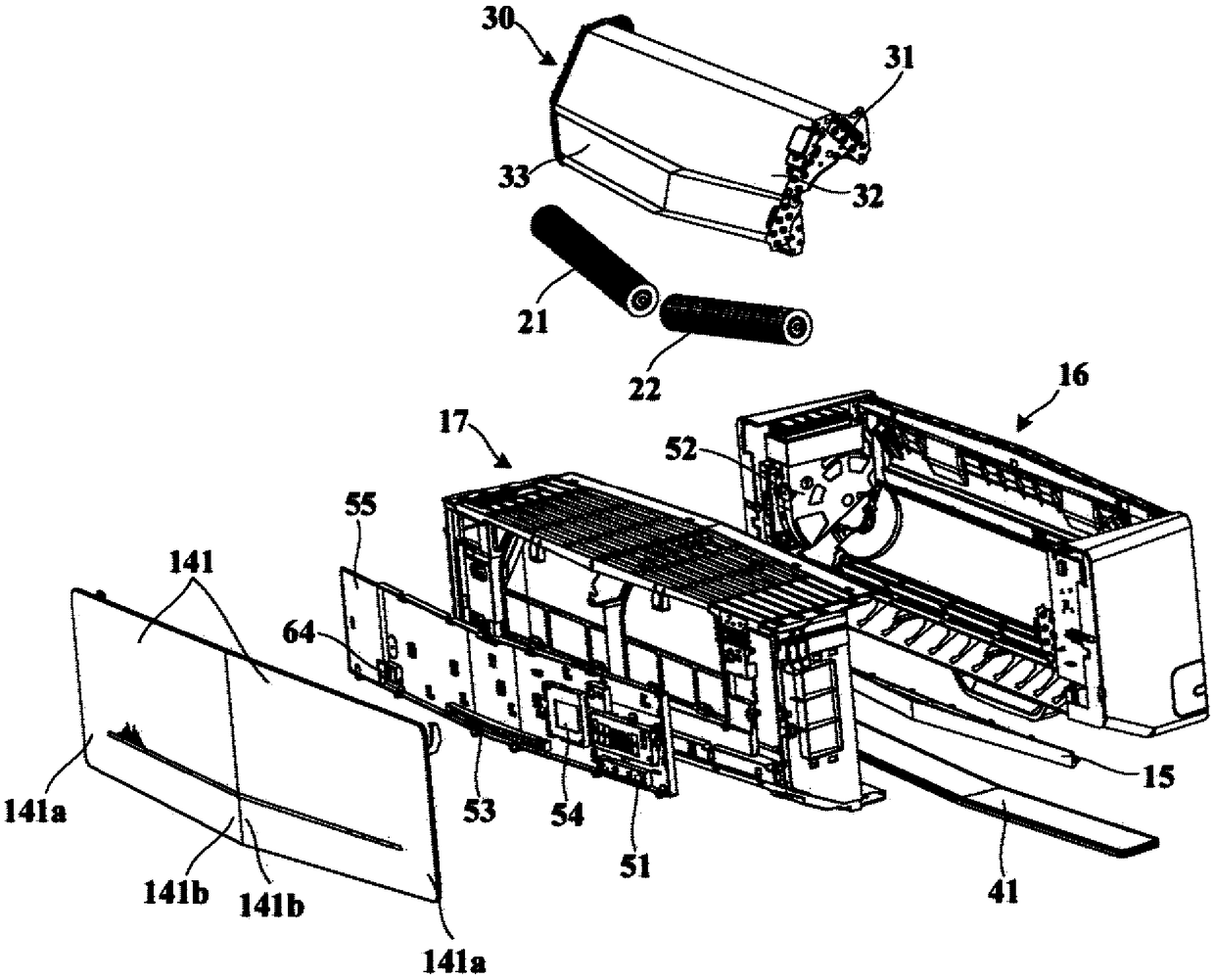

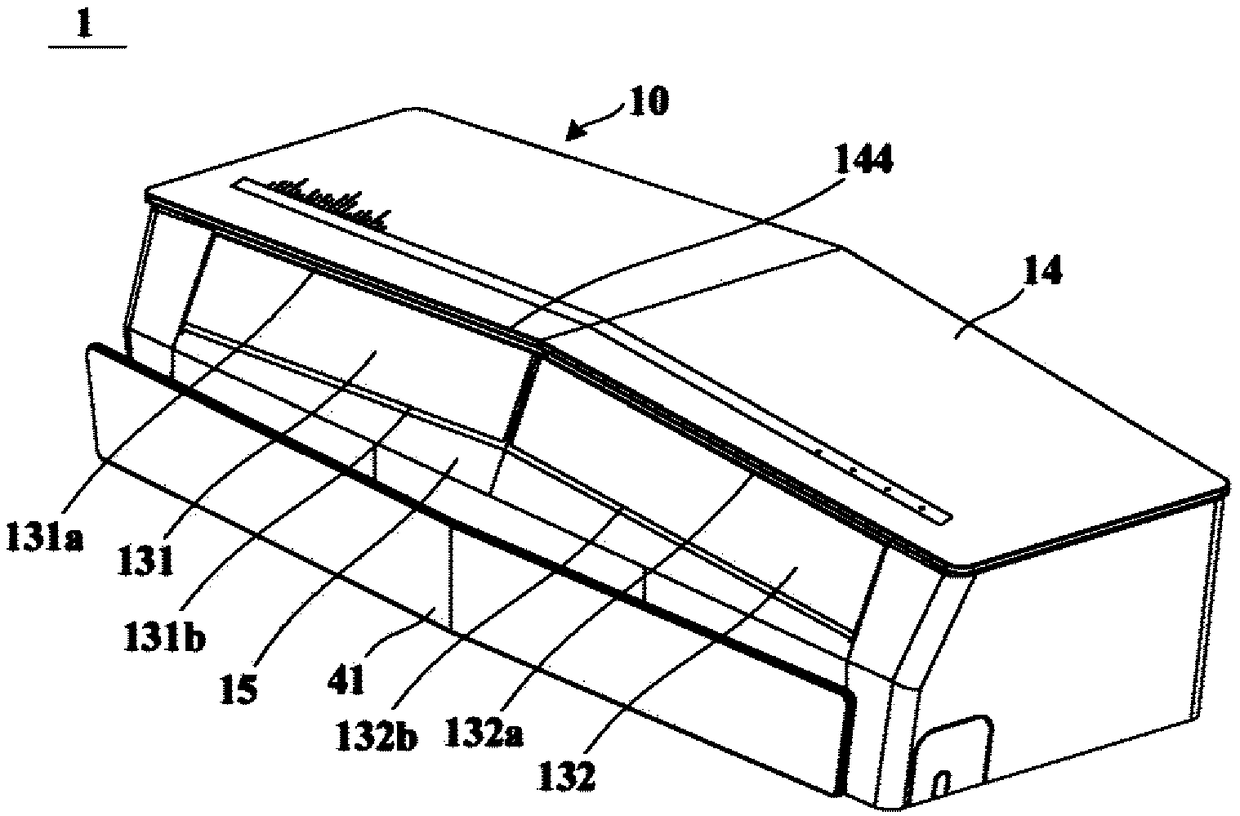

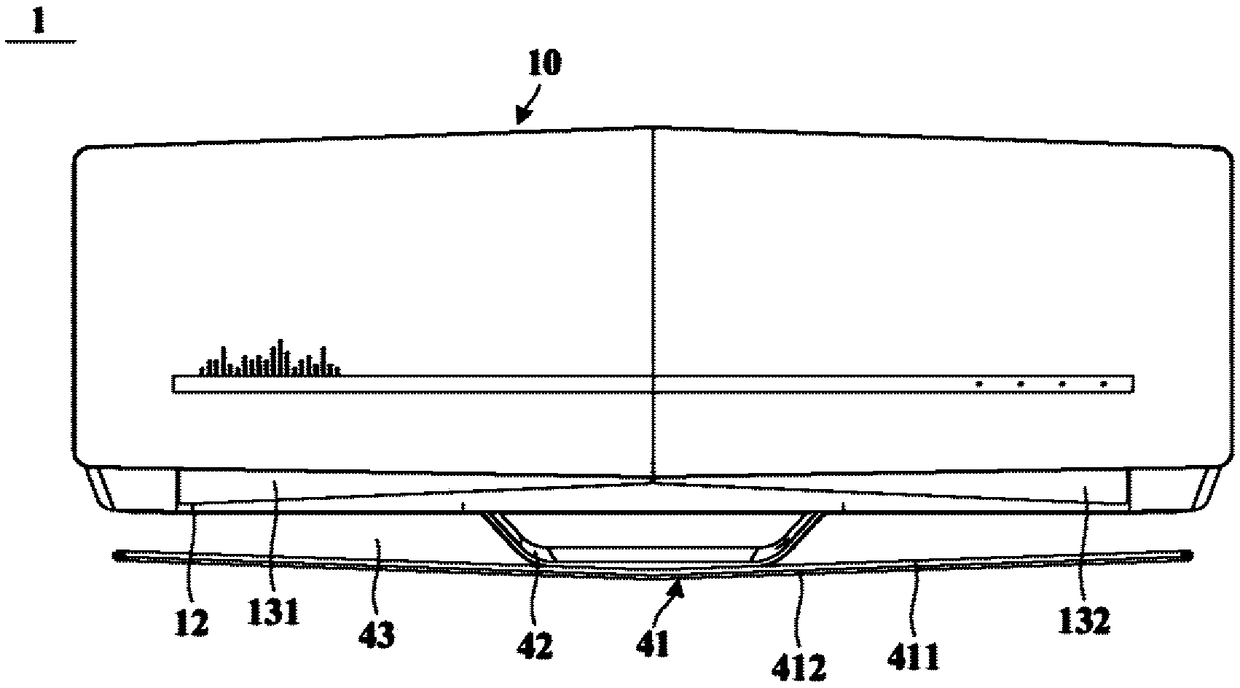

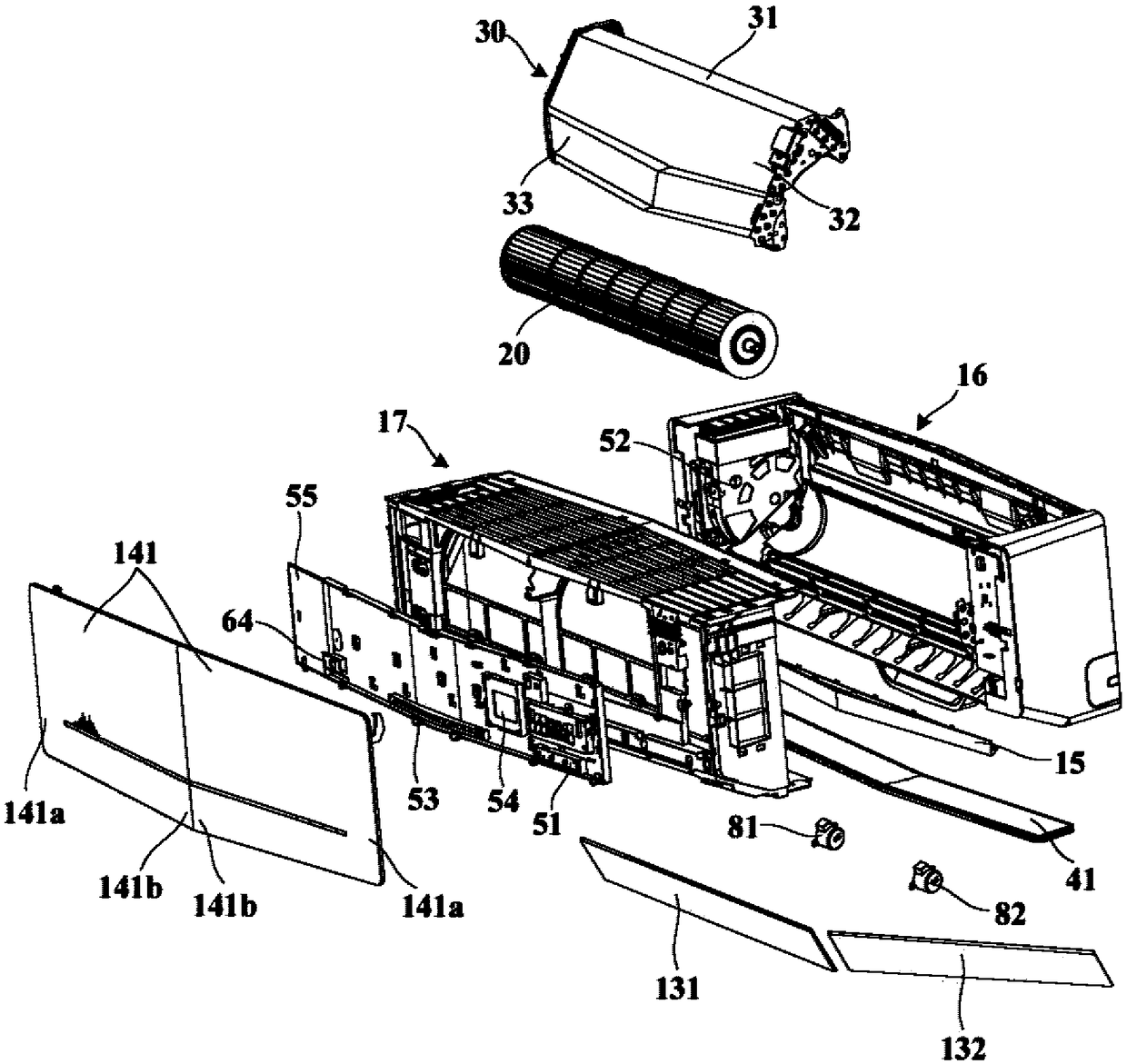

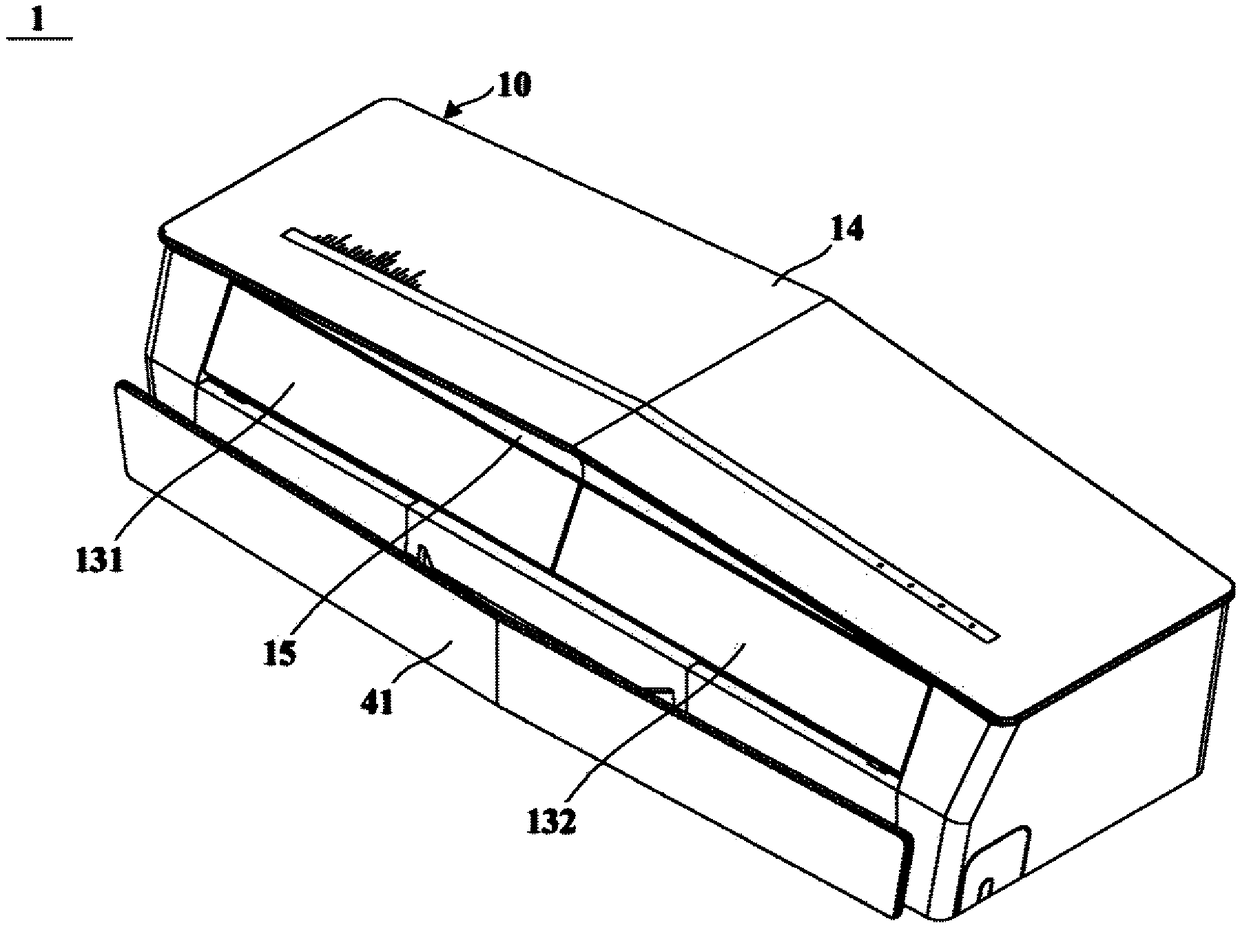

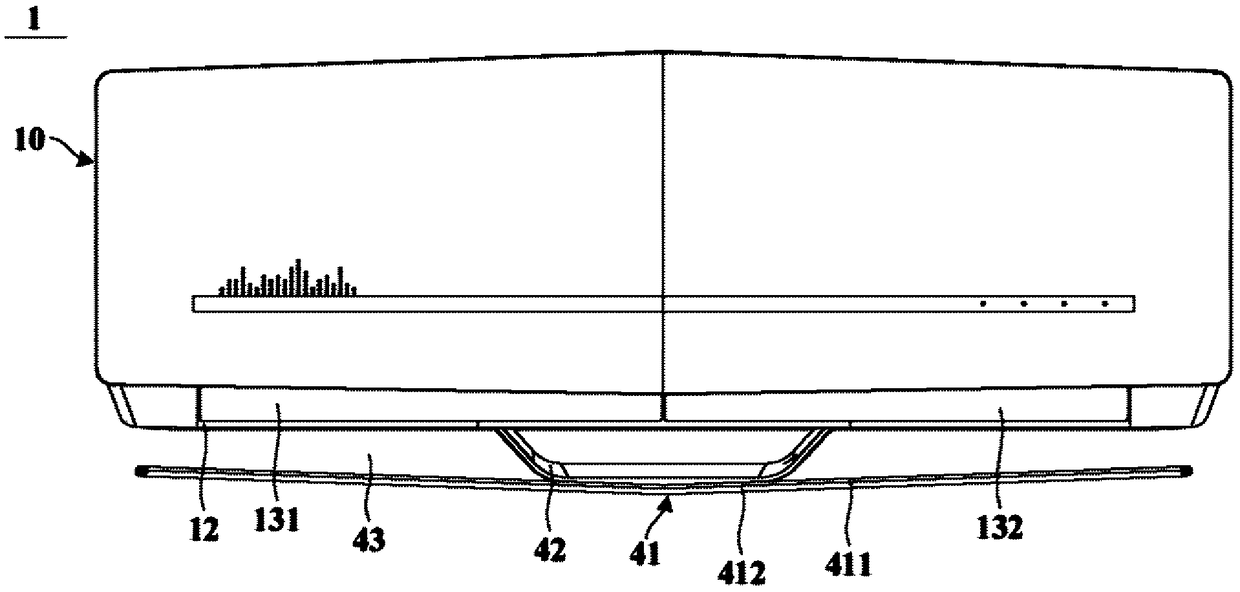

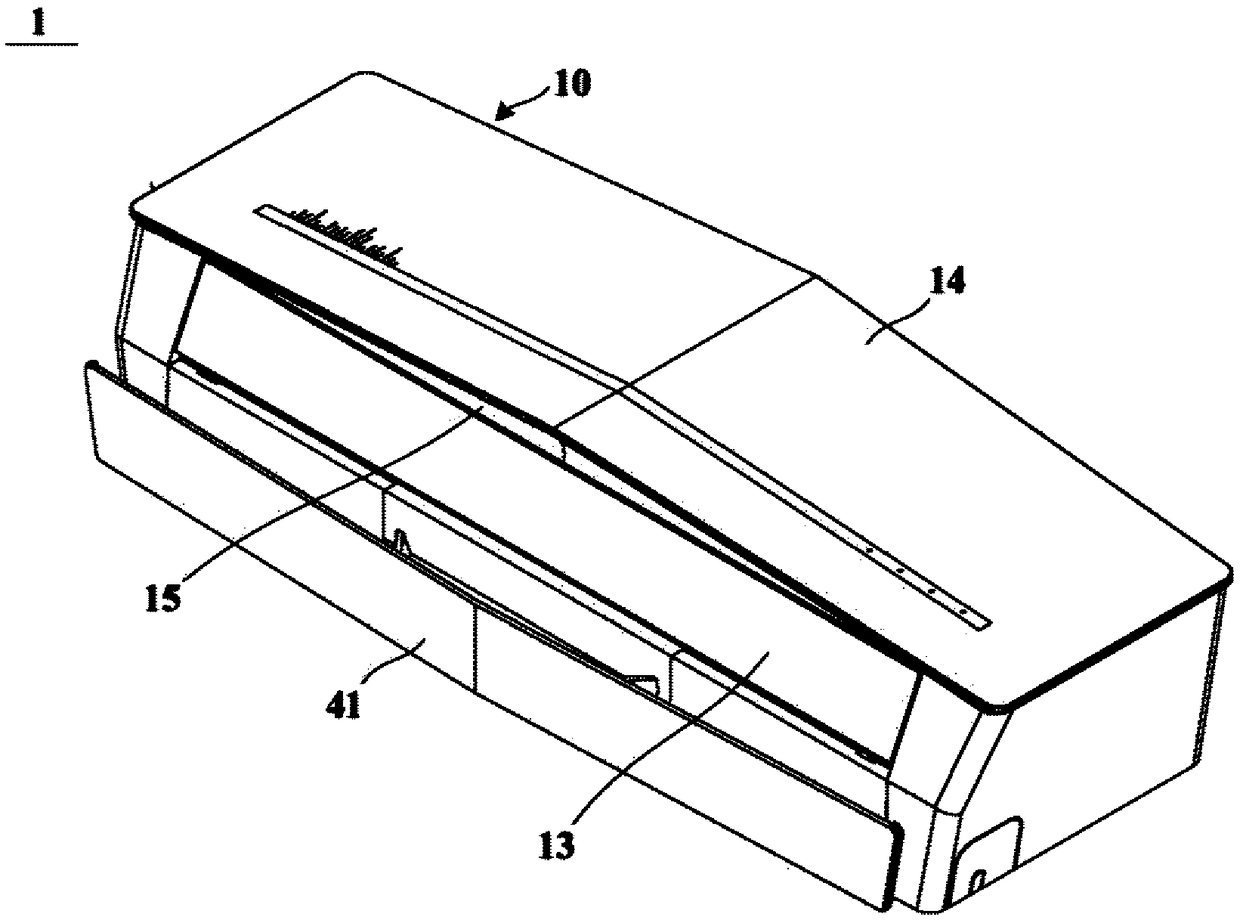

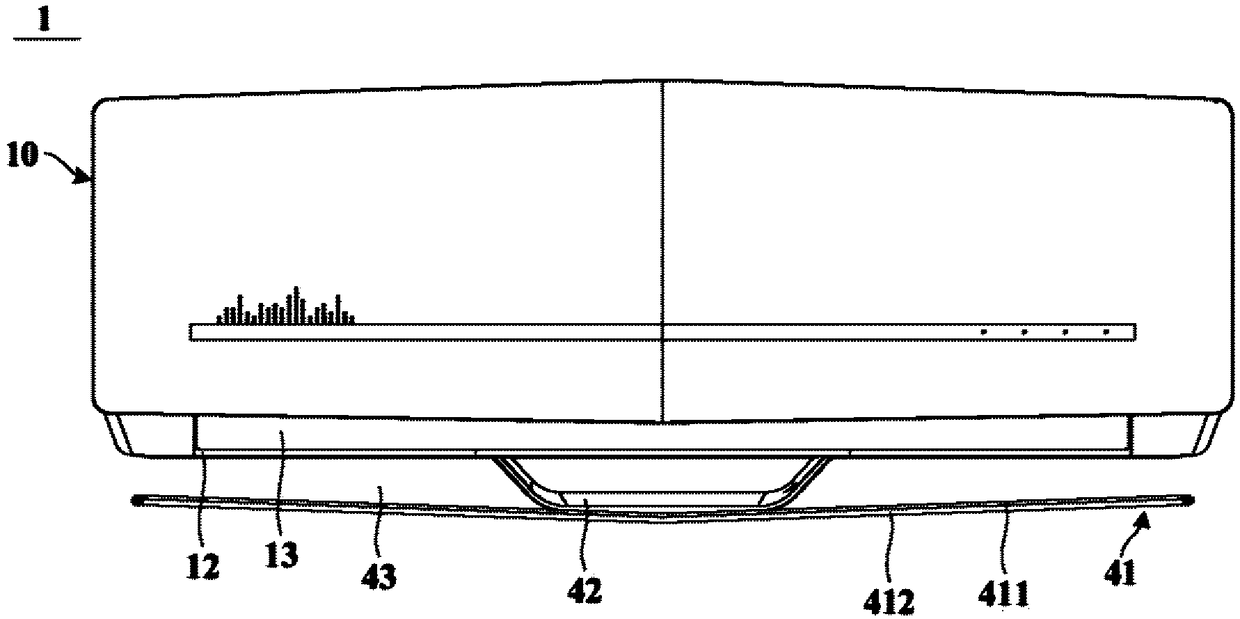

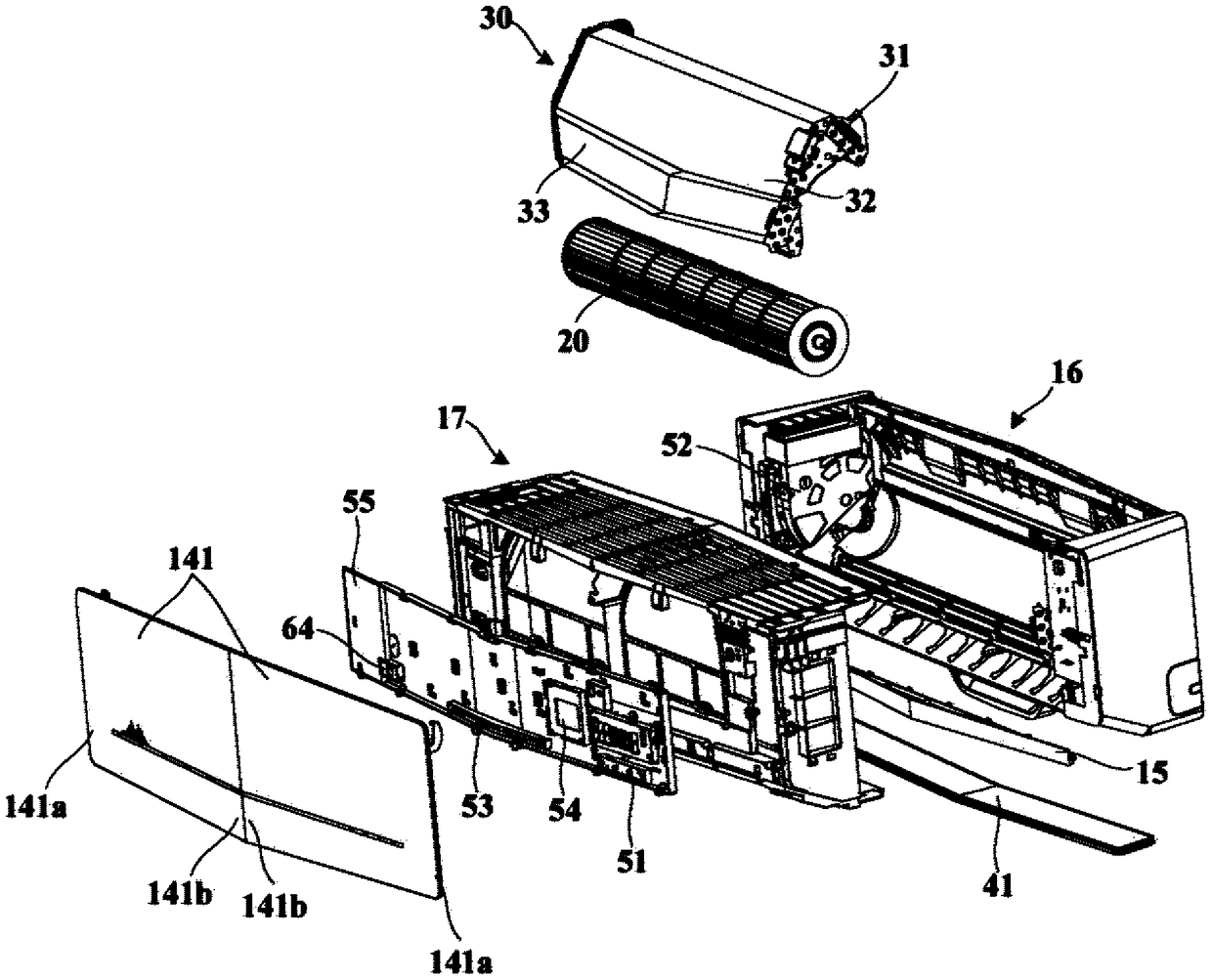

The invention relates to a wall-mounted air conditioner indoor unit. The wall-mounted air conditioner indoor unit comprises a machine shell and a cross-flow fan; the machine shell is provided with anair inlet and a strip-shaped air outlet which is used for supplying air into a room, two independent air guide plates which are arranged side by side in the extending direction of the air outlet are arranged at the air outlet, and each air guide plate is configured to be controlled to be pivoted around a rotating shaft, which is parallel to the extending direction of the air outlet, of the corresponding air guide plate so as to be used for adjusting an opening and closing state and / or an air outlet direction of an air outlet area corresponding to the air outlet and the corresponding air guideplate, and the rotating shafts of the two air guide plates are collinear or parallel; and the cross-flow fan is configured to be arranged in the machine shell in a rotatable mode around a rotating shaft which extends transversely along the machine shell, and comprises a variable-diameter impeller, wherein the radius of the variable-diameter impeller is gradually increased from the transverse two ends of the machine shell to the middle of the machine shell. Therefore, multi-mode dual-area air supply can be realized, moreover, strong air supply can be realized in a middle area of the air outlet,soft air supply can be realized in two end areas of the air outlet, moreover, soft transition from the middle area to the two end areas can be achieved, and meanwhile, different requirements of usersrequiring for instant-cooling and instant-heating effects and users requiring for soft and comfortable effects are met.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

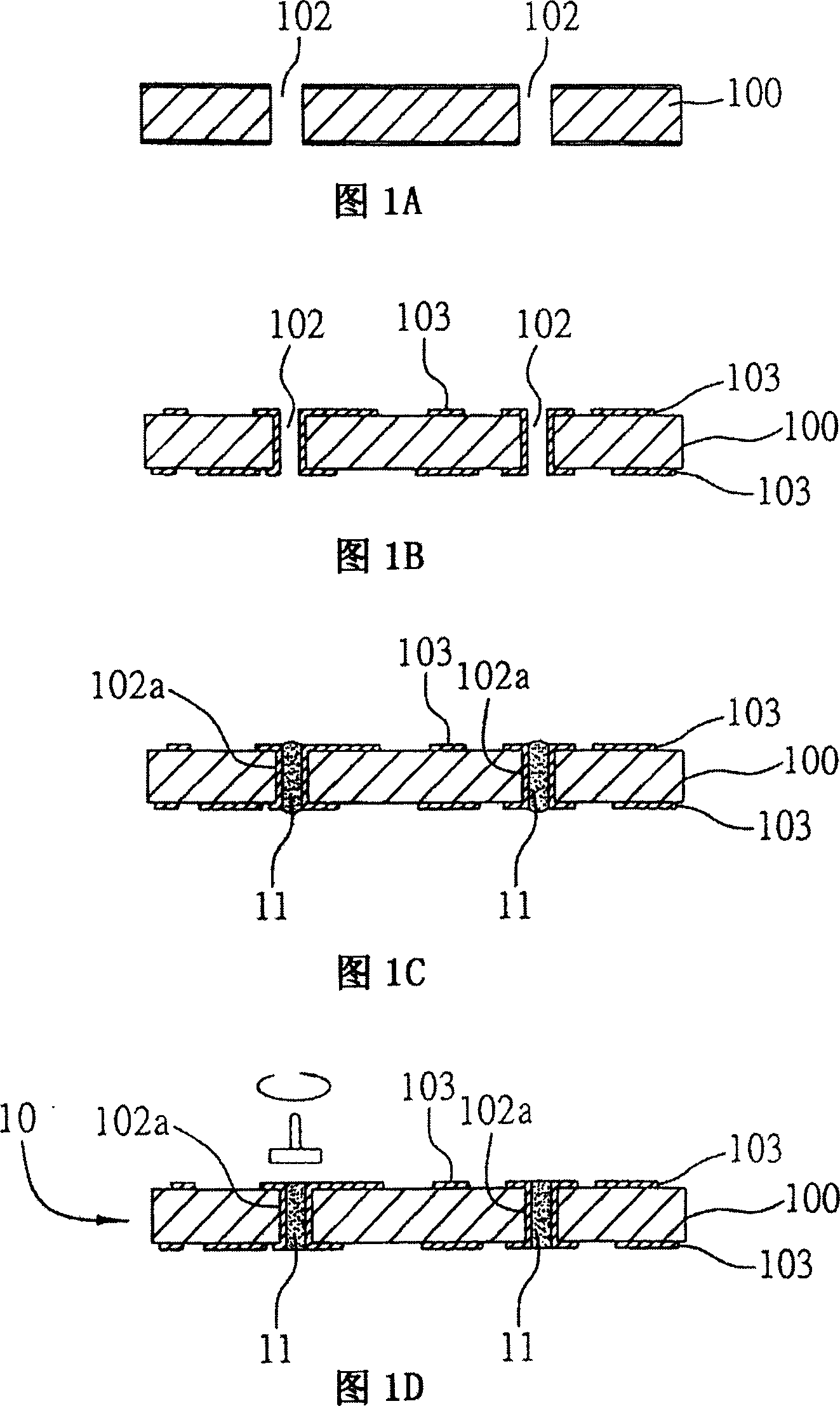

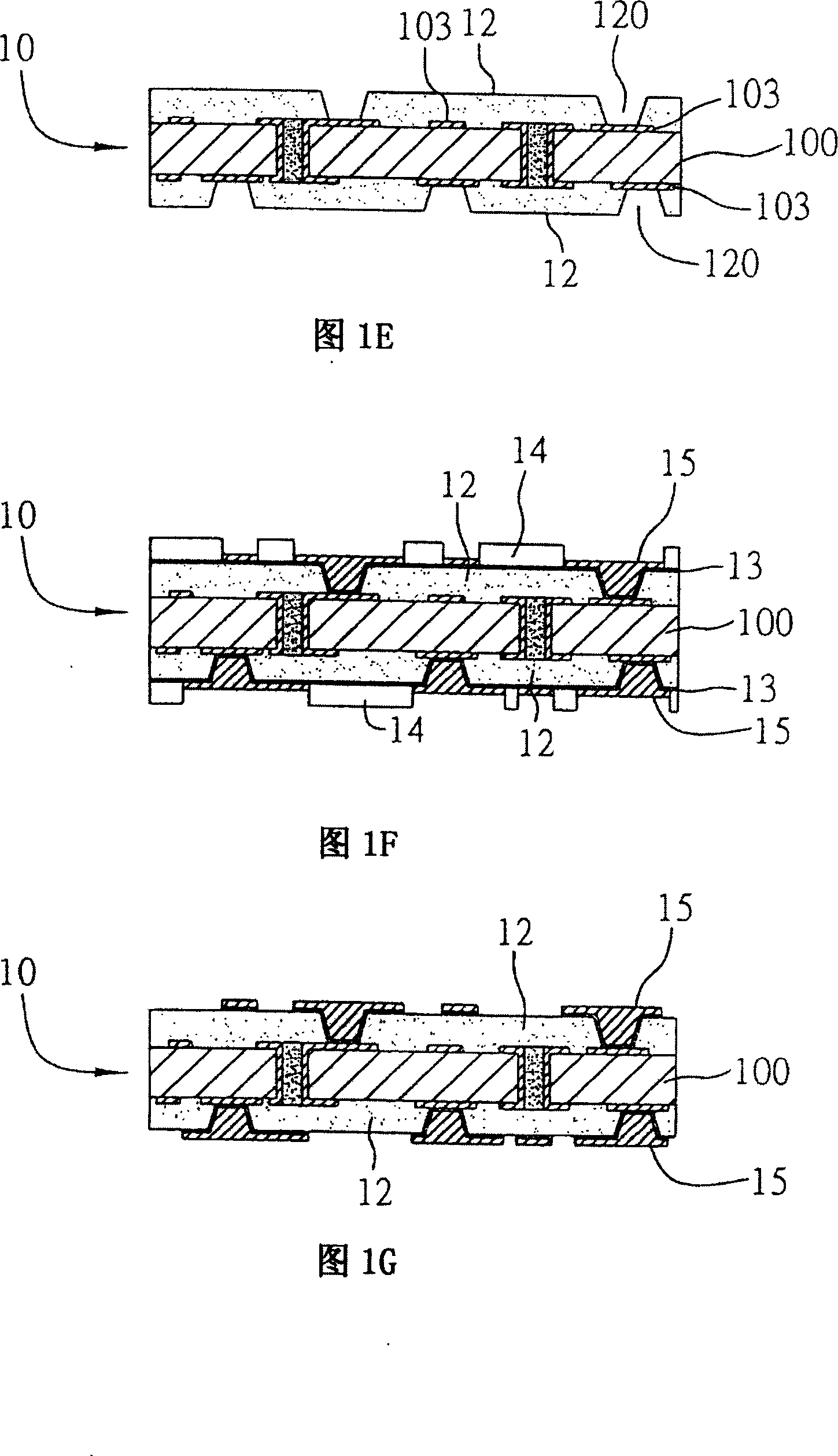

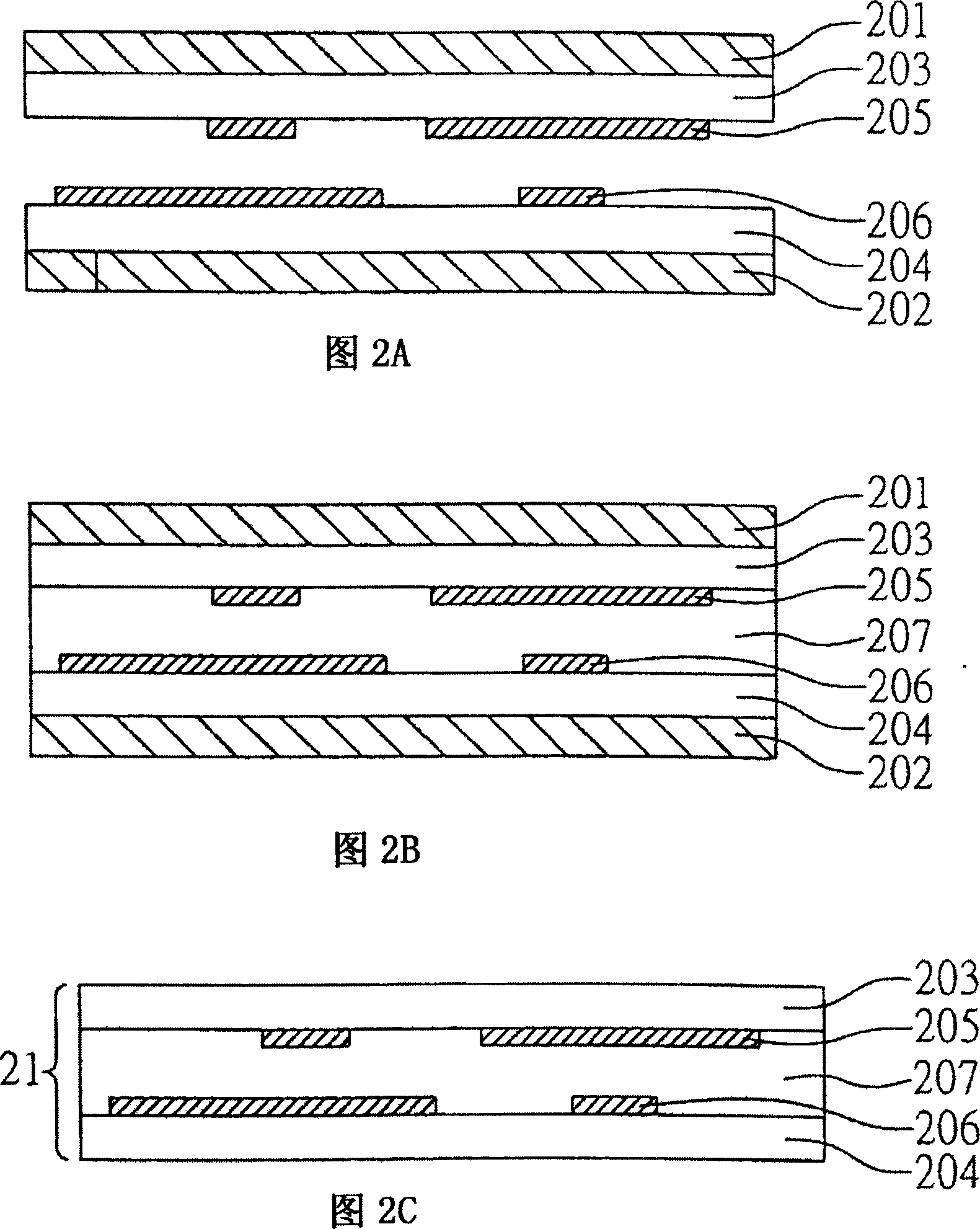

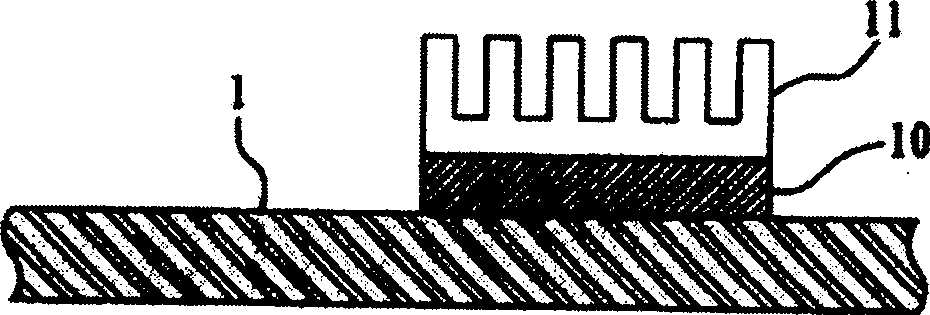

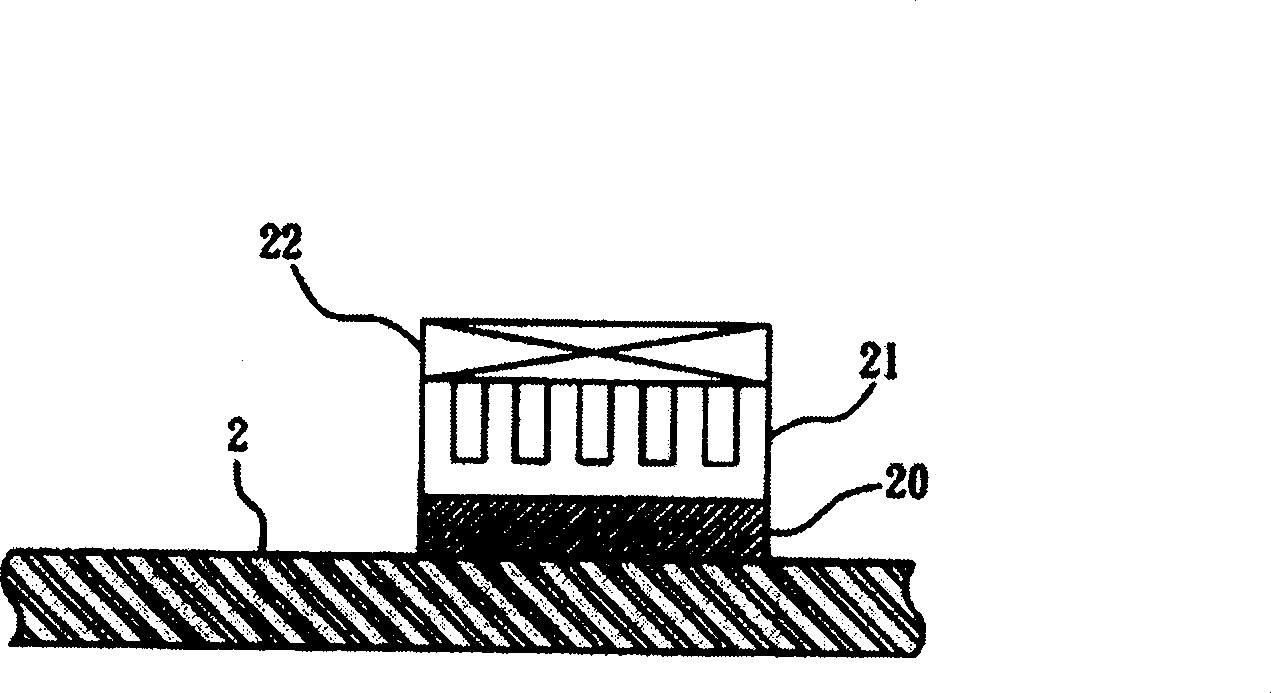

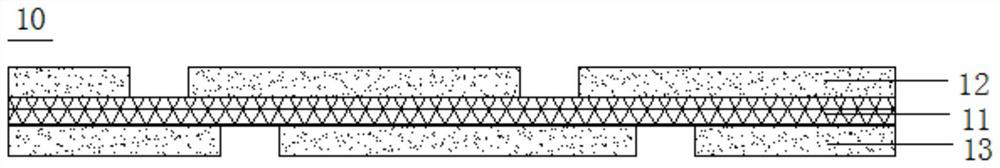

Circuit board structure and making method

InactiveCN1980540AShorten process timeReduce process costPrinted electric component incorporationMultilayer circuit manufactureElectric propertiesEngineering

Owner:PHOENIX PRECISION TECH CORP

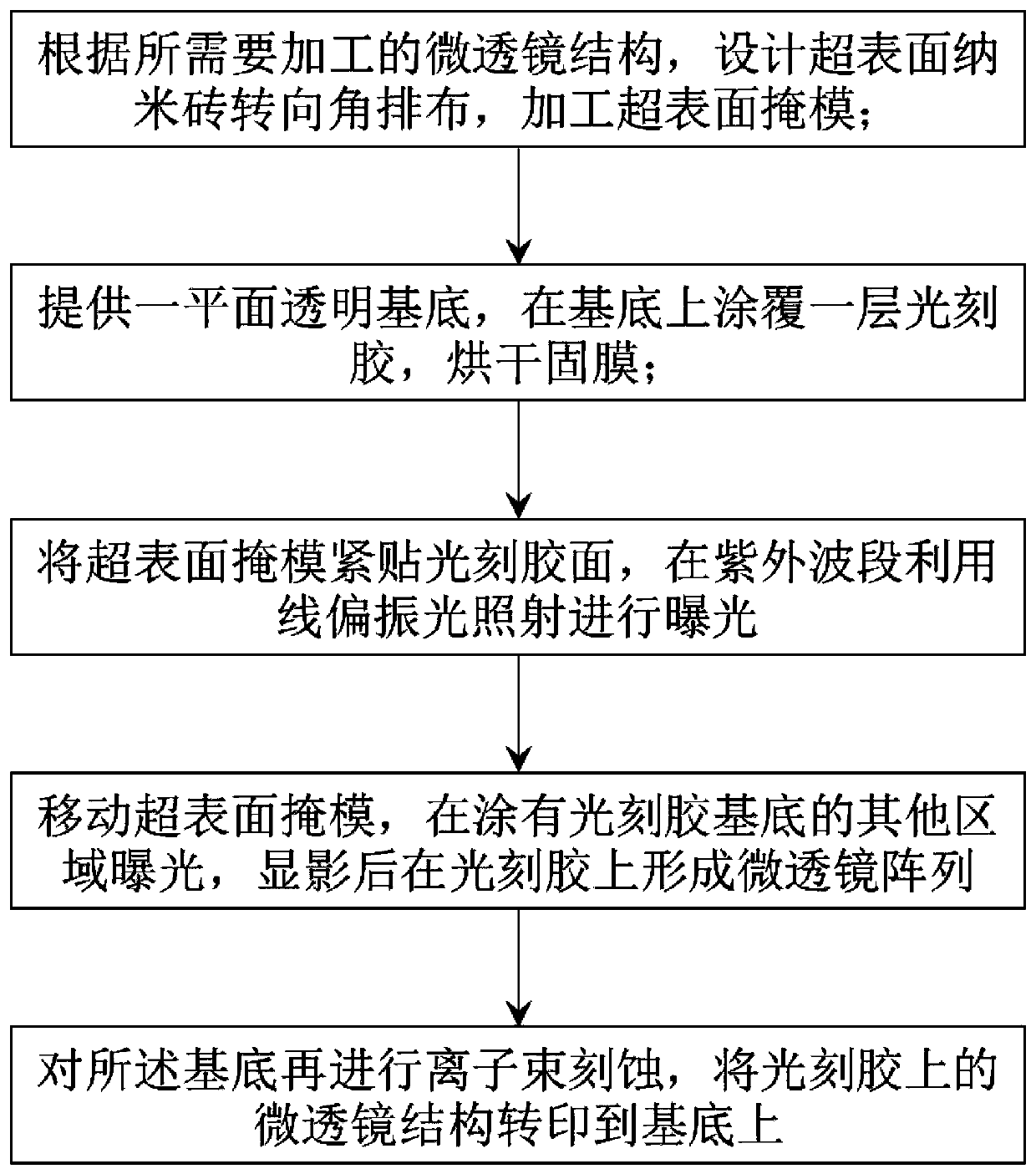

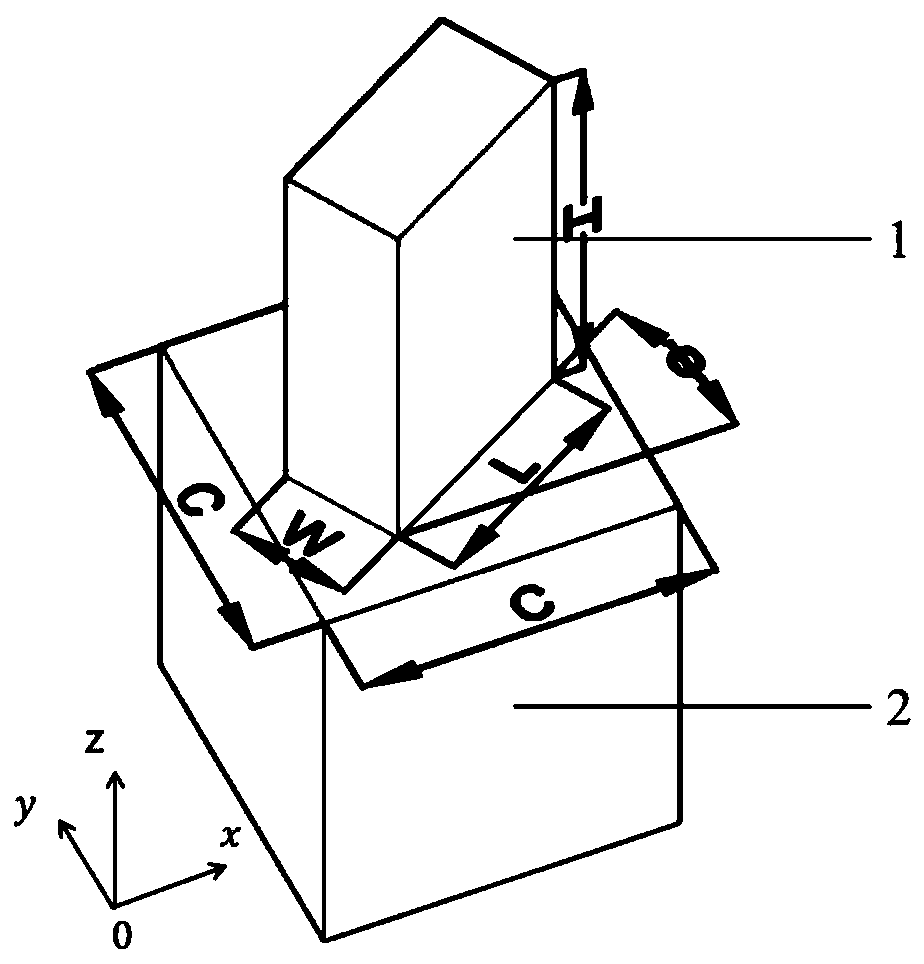

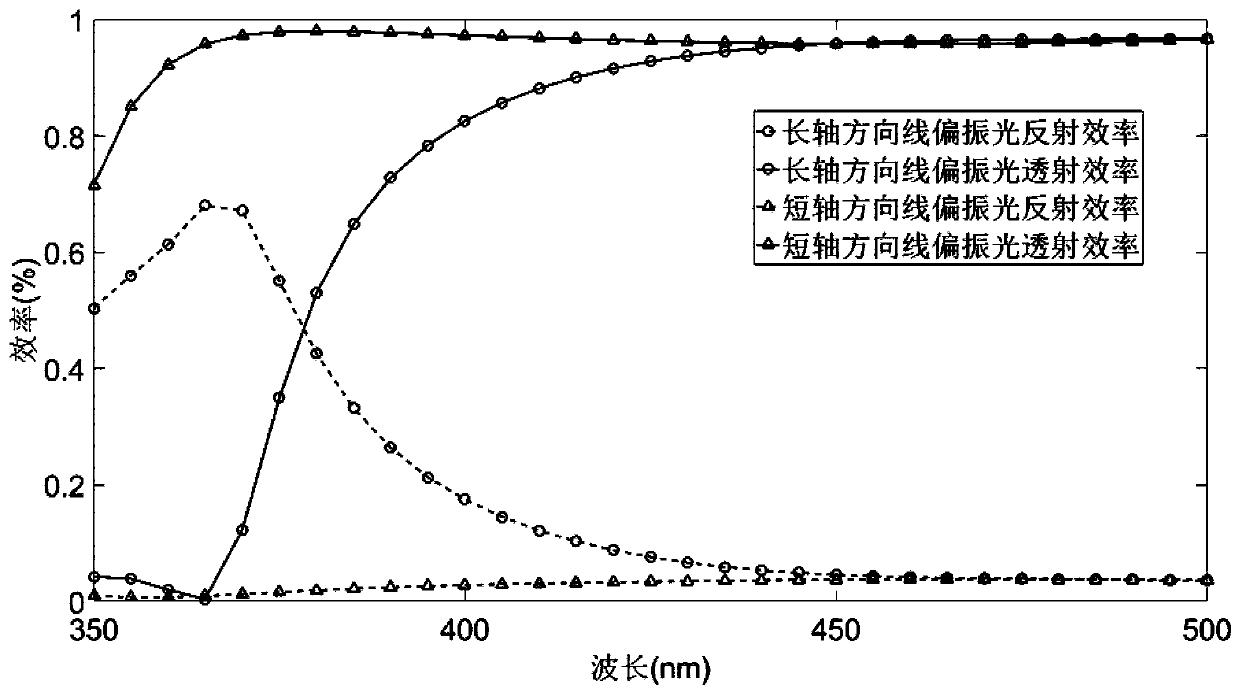

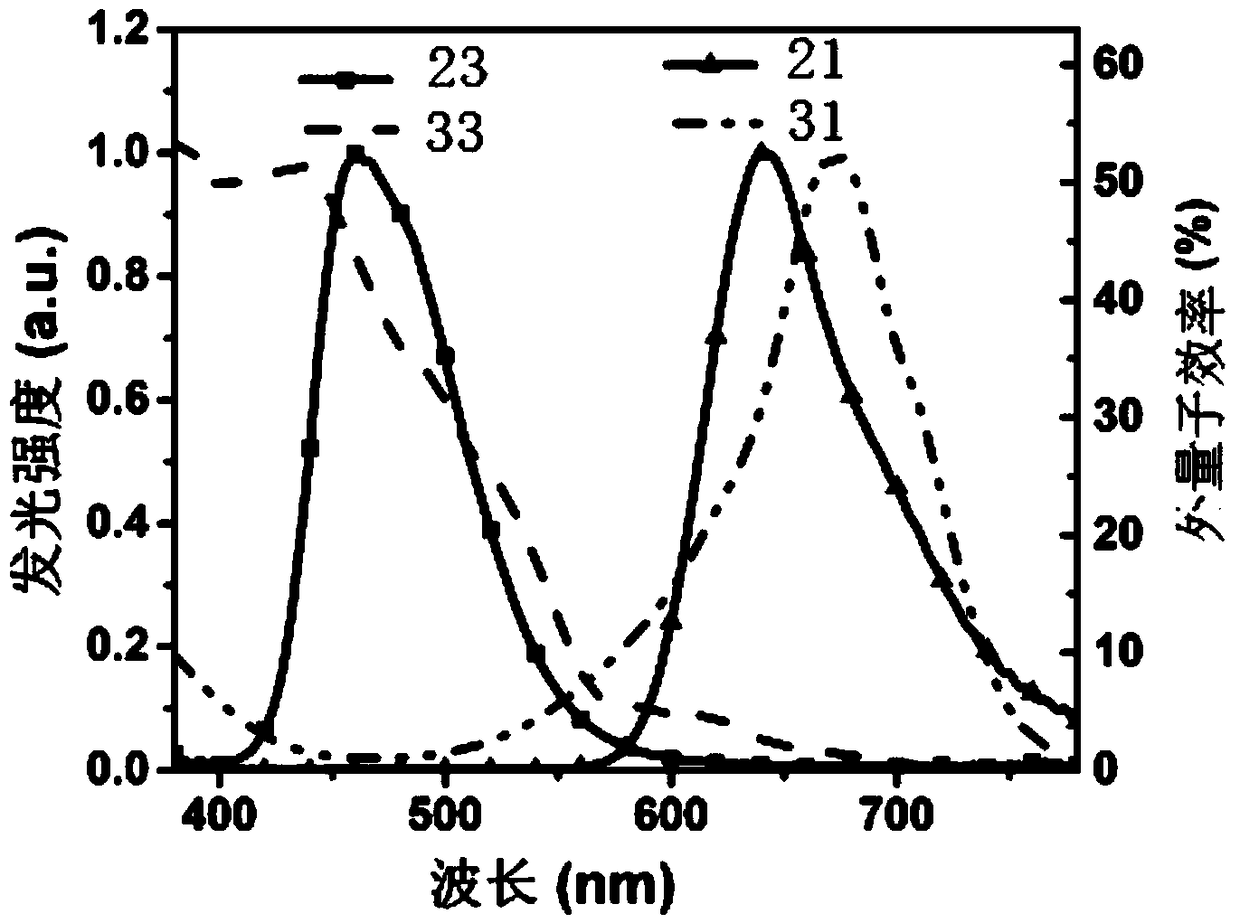

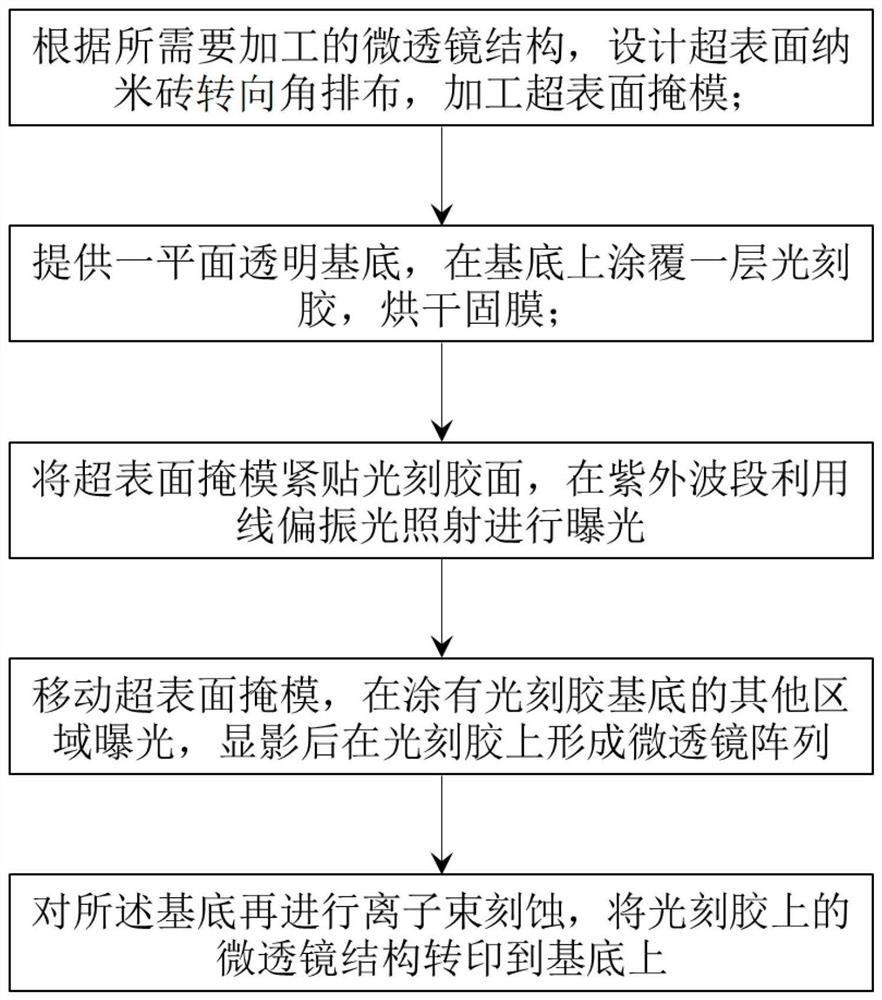

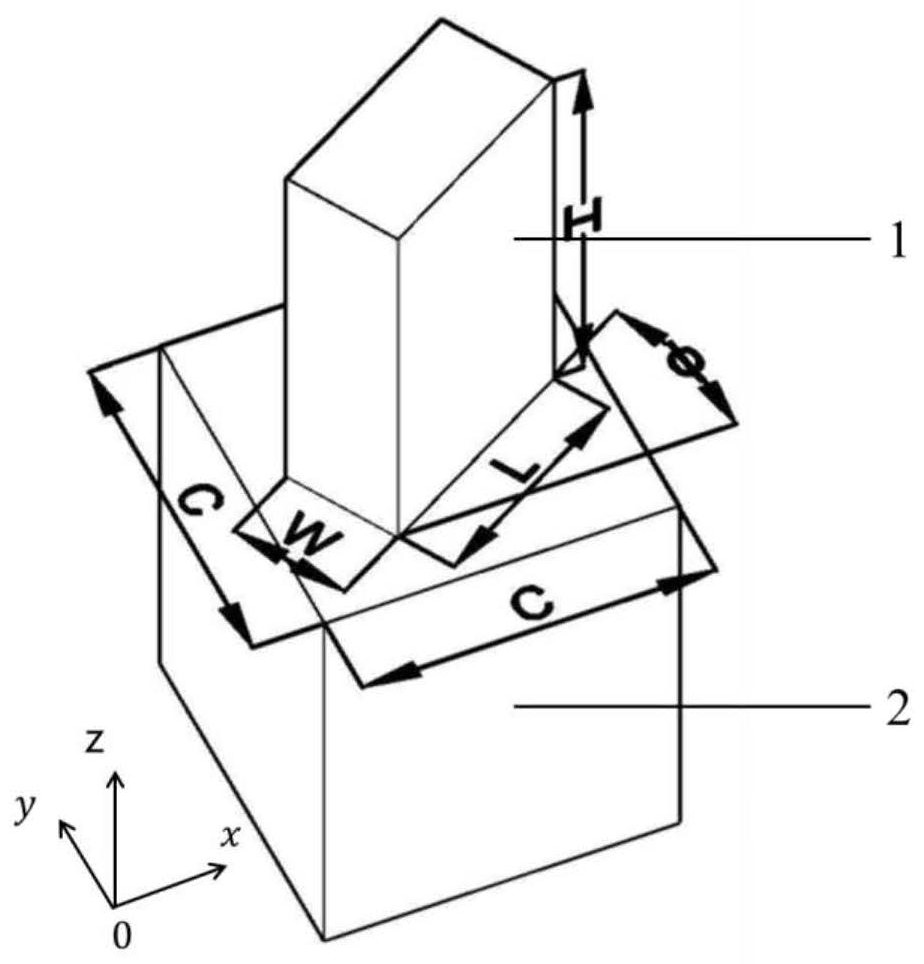

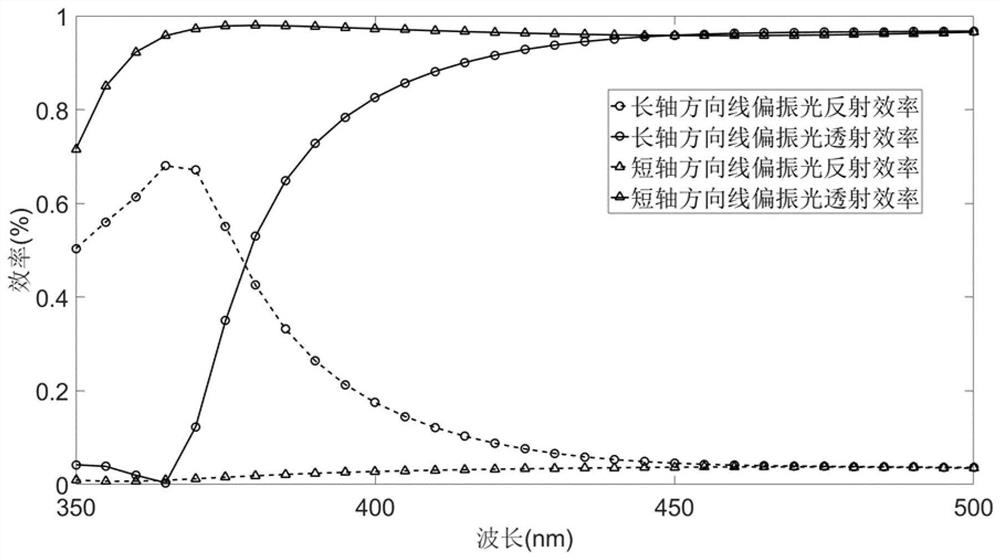

Method for manufacturing microlens array

InactiveCN110673238AContinuous fine adjustmentSmall sizePhotomechanical apparatusLensImage resolutionEngineering

The invention relates to a method for manufacturing a microlens array, and the method comprises the following steps of designing and preparing a super-surface mask; providing a transparent substrate,coating a photoresist on the substrate, and drying and solidifying the film; attaching the super-surface mask to the surface of the photoresist, making the linearly polarized light in the ultravioletband incident on the super-surface mask, and performing exposure on the corresponding photoresist area under the super-surface mask; moving the super-surface mask, and performing exposure on the otherareas of the photoresist until the exposure is completed on the required areas of the photoresist; developing the substrate coated with the photoresist, and forming a microlens array structure on theexposed photoresist after development; subjecting the substrate to ion beam etching by using the microlens array structure on the photoresist as a template, and transferring the microlens array structure on the photoresist to the substrate. The method provided by the invention improves the resolution of exposure by using a super-surface instead of a traditional mask plate, can directly realize continuous and precise adjustment of exposure dose, reduces costs and improves processing accuracy.

Owner:WUHAN UNIV

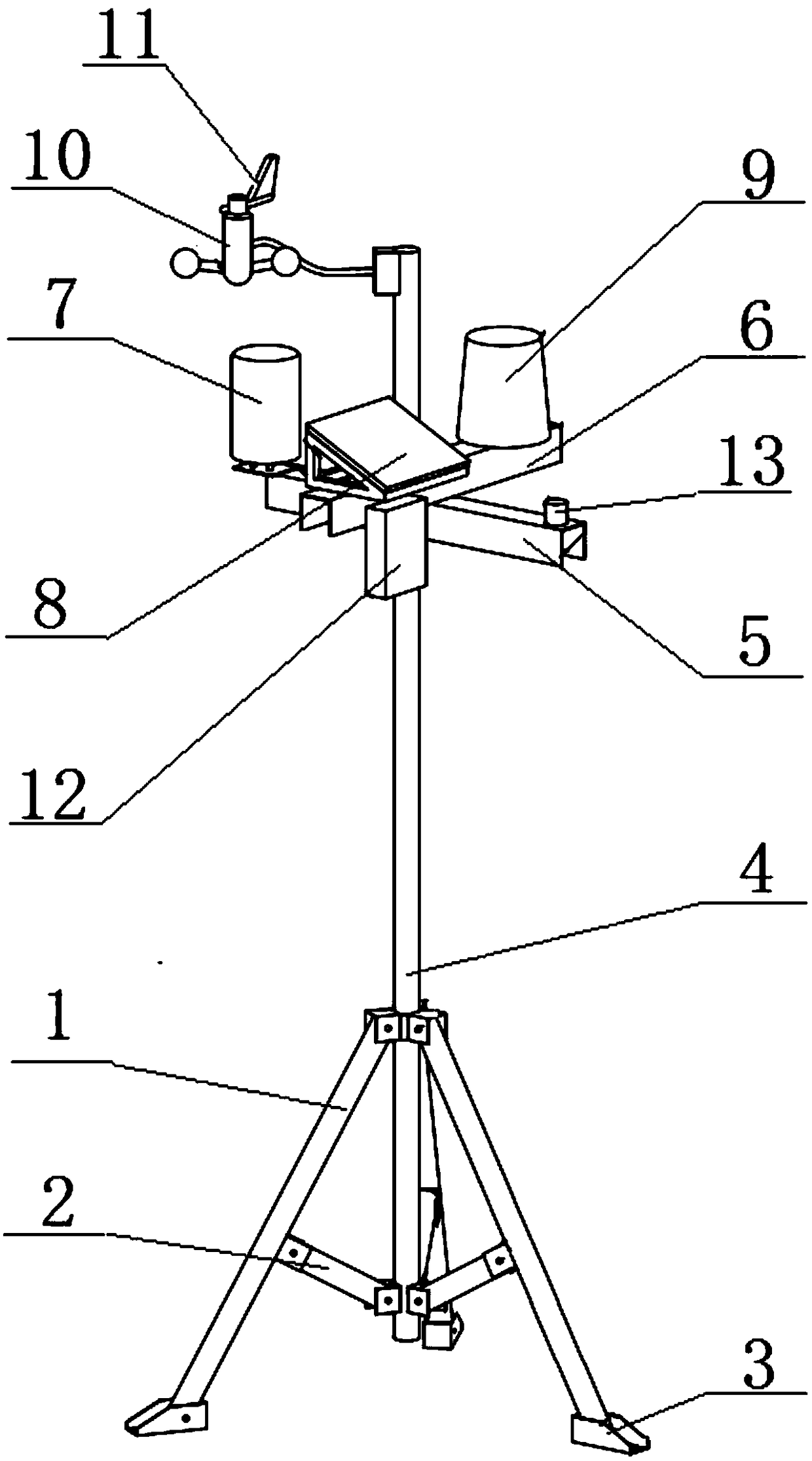

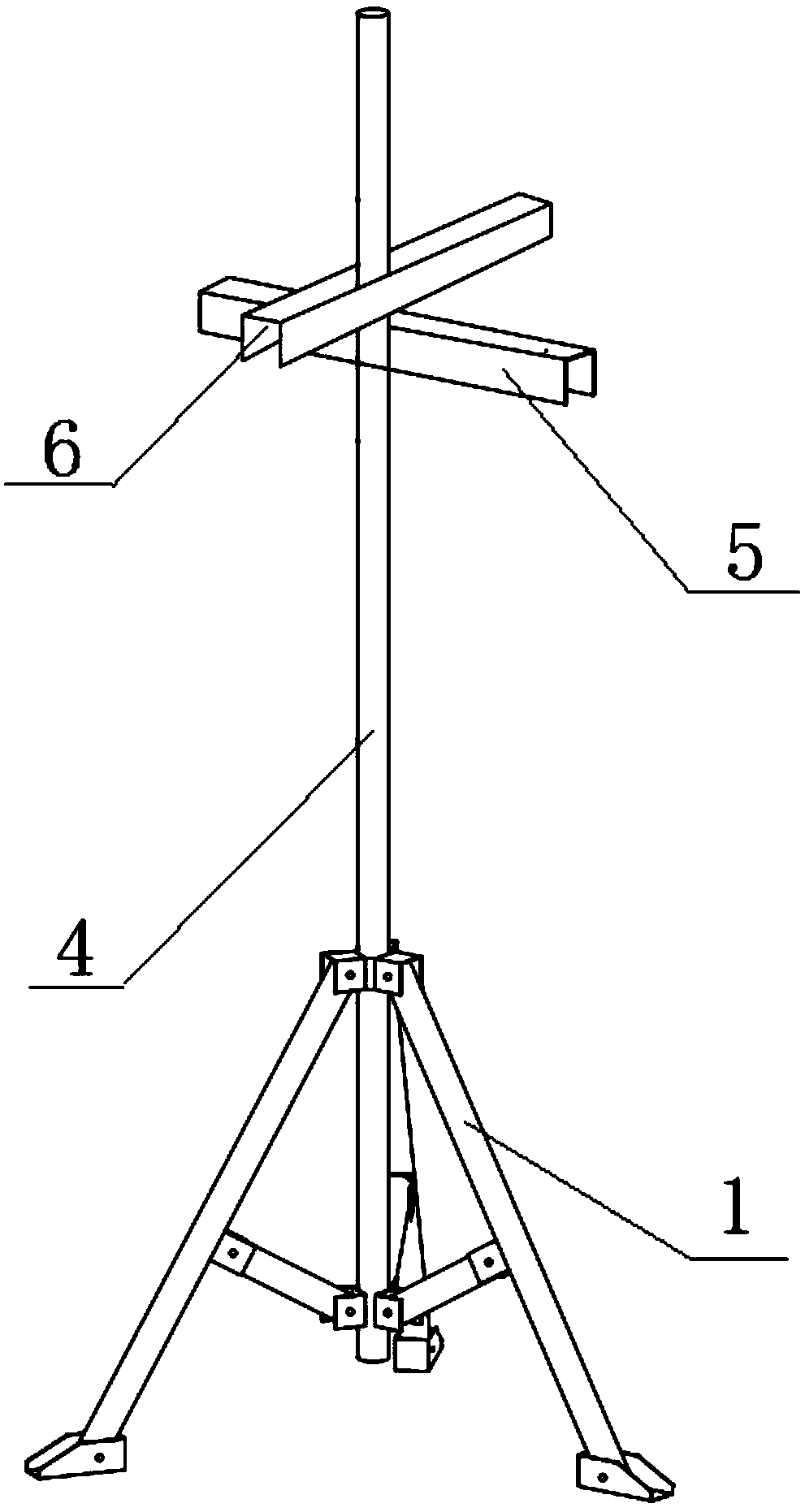

Small-sized meteorological environment monitoring integrated machine device

InactiveCN109471204AHigh degree of integrationIn line with the development trend of miniaturizationIndication of weather conditions using multiple variablesStands/trestlesData acquisitionMonitoring system

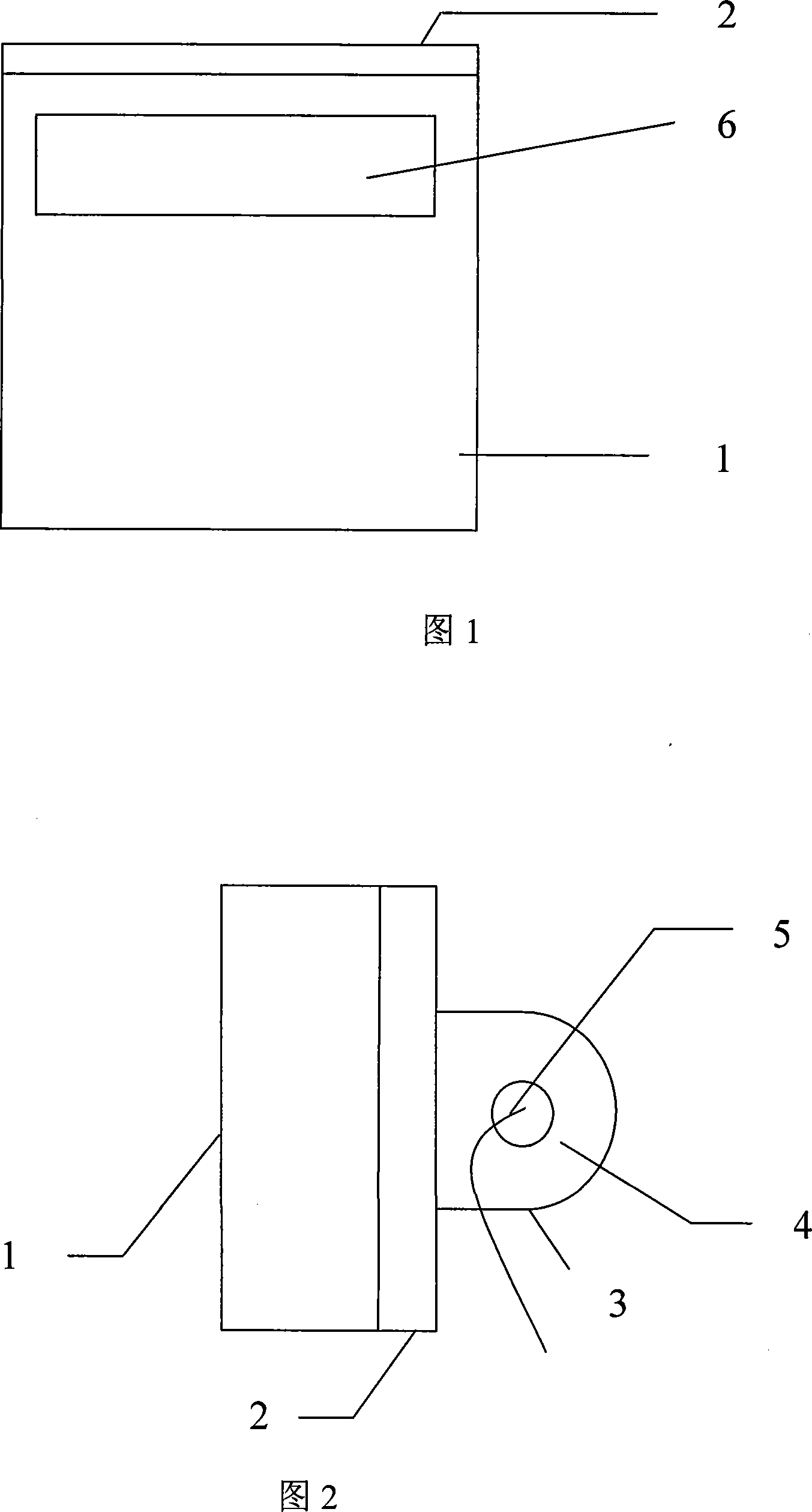

The invention relates to a small-sized meteorological environment monitoring integrated machine device, and belongs to the technical field of meteorological environment monitoring stations. The small-sized meteorological environment monitoring integrated machine device comprises a bracket and a monitoring device fixed on the upper part of the bracket, wherein the bracket comprises a tripod, a mainsupporting rod and a fixed transverse frame. The main supporting rod is vertically arranged through the tripod positioned at the bottom, the tripod and the bottom end of the main supporting rod are assisted and reinforced by a reinforcing rod, and the bottom end of the tripod is provided with a horizontal foot which is contacted with the ground; the fixed transverse frame comprises a fixed transverse frame I and a fixed transverse frame II which are crossly arranged, wherein the middle part of the fixed transverse frame penetrates through the upper part of the main supporting rod; the monitoring device comprises a sensor node and a data collector, wherein the sensor node is respectively positioned at the top end of the main supporting rod and the end parts of the fixed transverse frame Iand the fixed transverse frame II; the data collector is positioned on the bottom side of the fixed transverse frame. The integration degree is high, and the portable installation and a data acquisition device are in accordance with the development trend of the miniaturization of an electronic monitoring system.

Owner:青岛中农万联科技有限公司

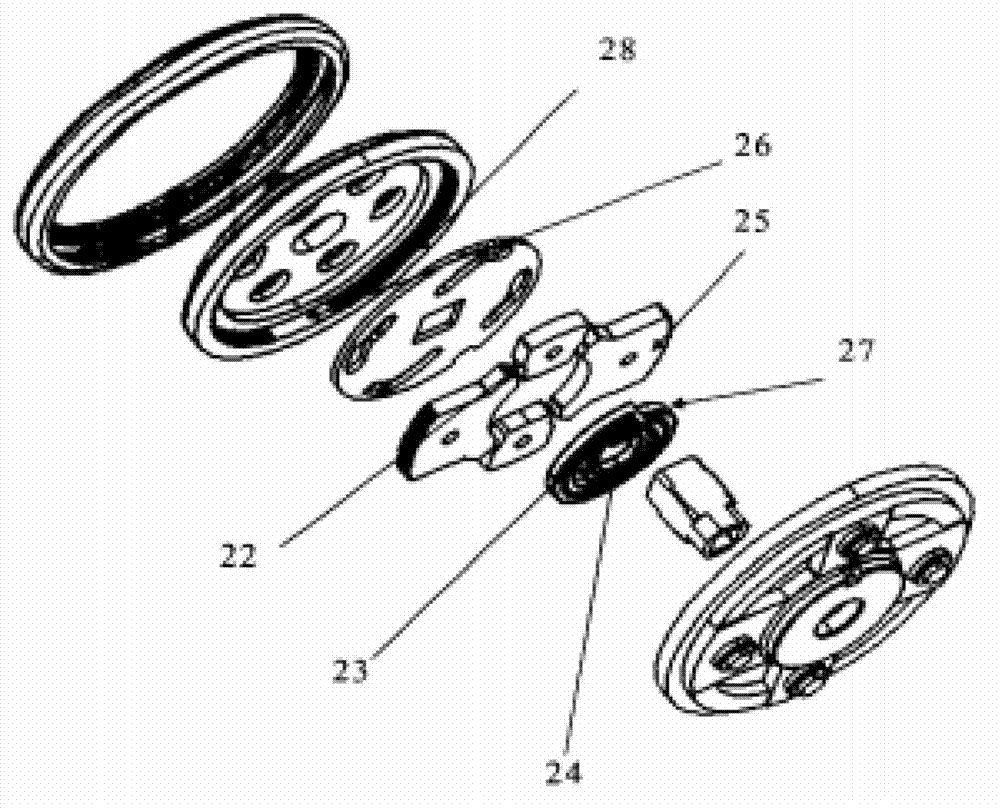

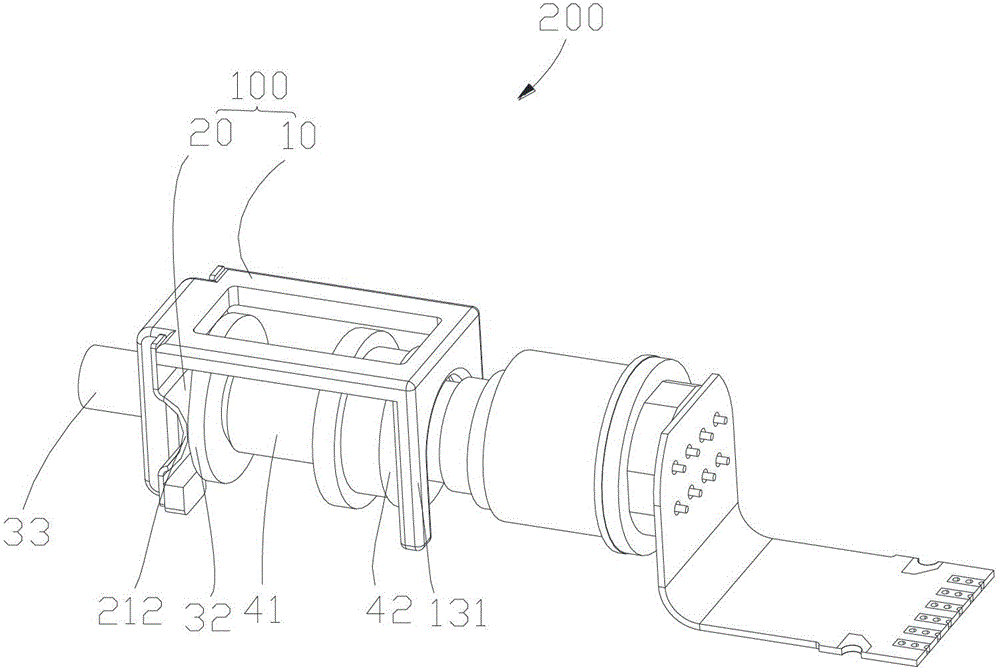

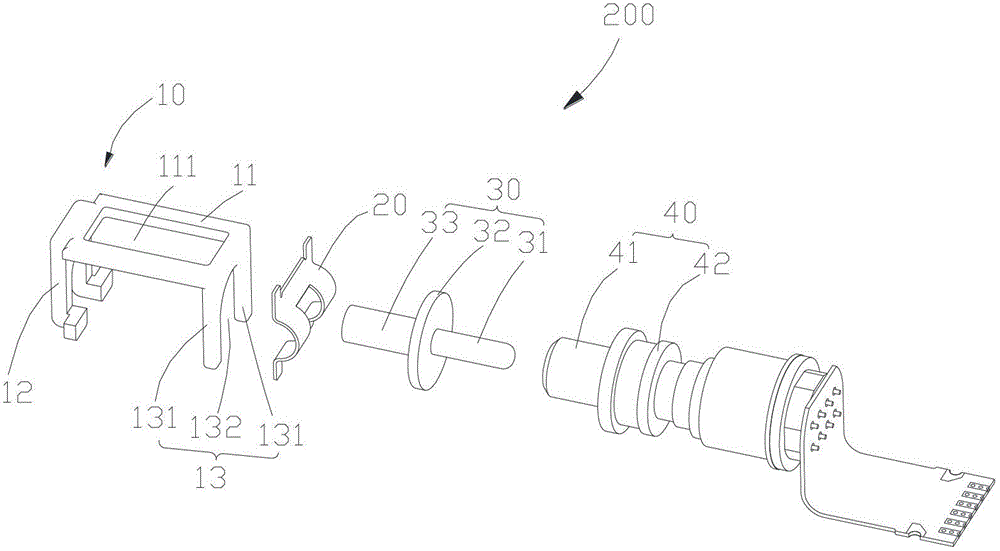

Seat and its angle regulator

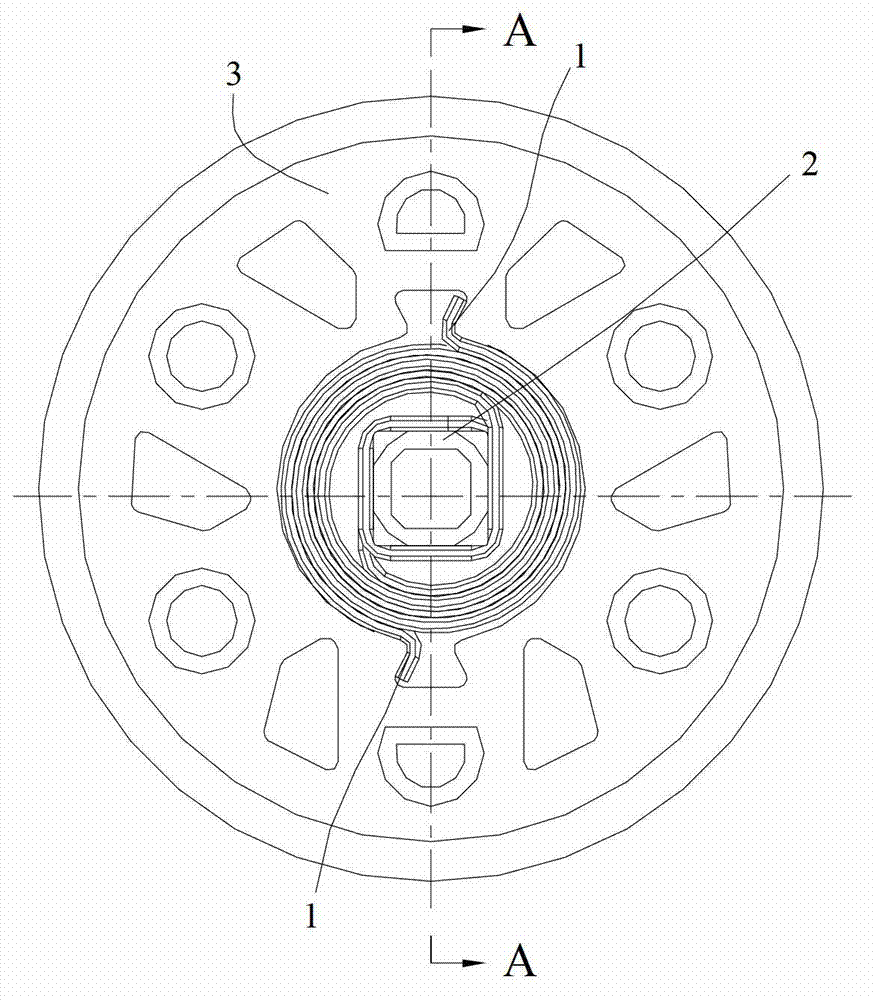

InactiveCN103070564ASimple structureEasy to implementStoolsMovable seatsAxial projectionFriction force

The invention discloses a seat angle regulator. The seat angle regulator comprises return springs arranged between a camshaft and a fixed part to generate elastic deformation during the rotation of the camshaft relative to the fixed part in order to control the locking or unlocking of the seat angle regulator; the middle of the fixed part has an inside concave counter bore, the return springs are arranged in the inside concave counter hole, and there is at least one group of the return springs; and each group has two return springs symmetrically arranged relative to the revolving axis of the camshaft in an axial projection plane. The completely-symmetric fixing mode of the two return springs of each group provides same-direction torques, and simultaneously side forces generated by the two return springs are equal in size and are opposite in direction, so the side forces offset, thereby a case that the return springs only provide the torques for the angle regulator without generating additional frictional force is guaranteed. The invention also provides a seat having the seat regular on the basis of the above scheme.

Owner:HUBEI AVIATION PRECISION MASCH TECH CO LTD

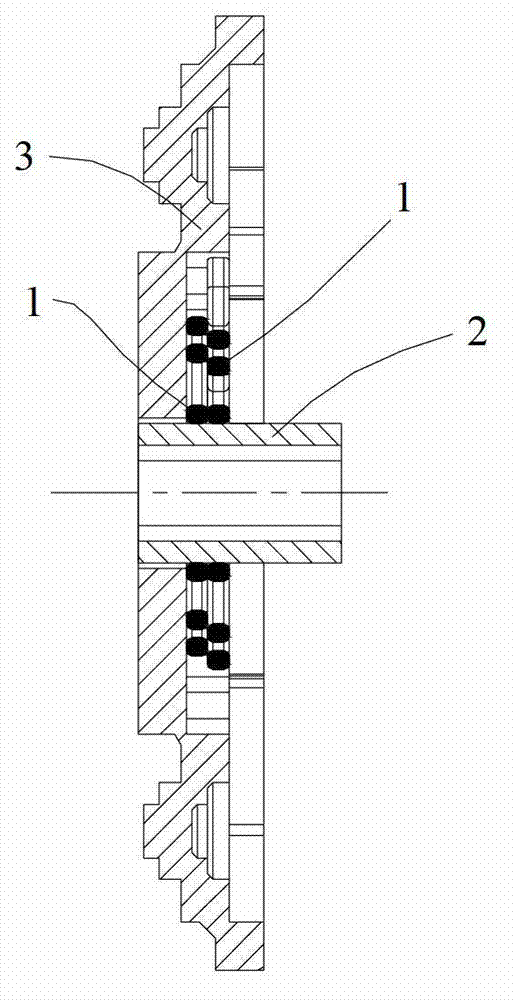

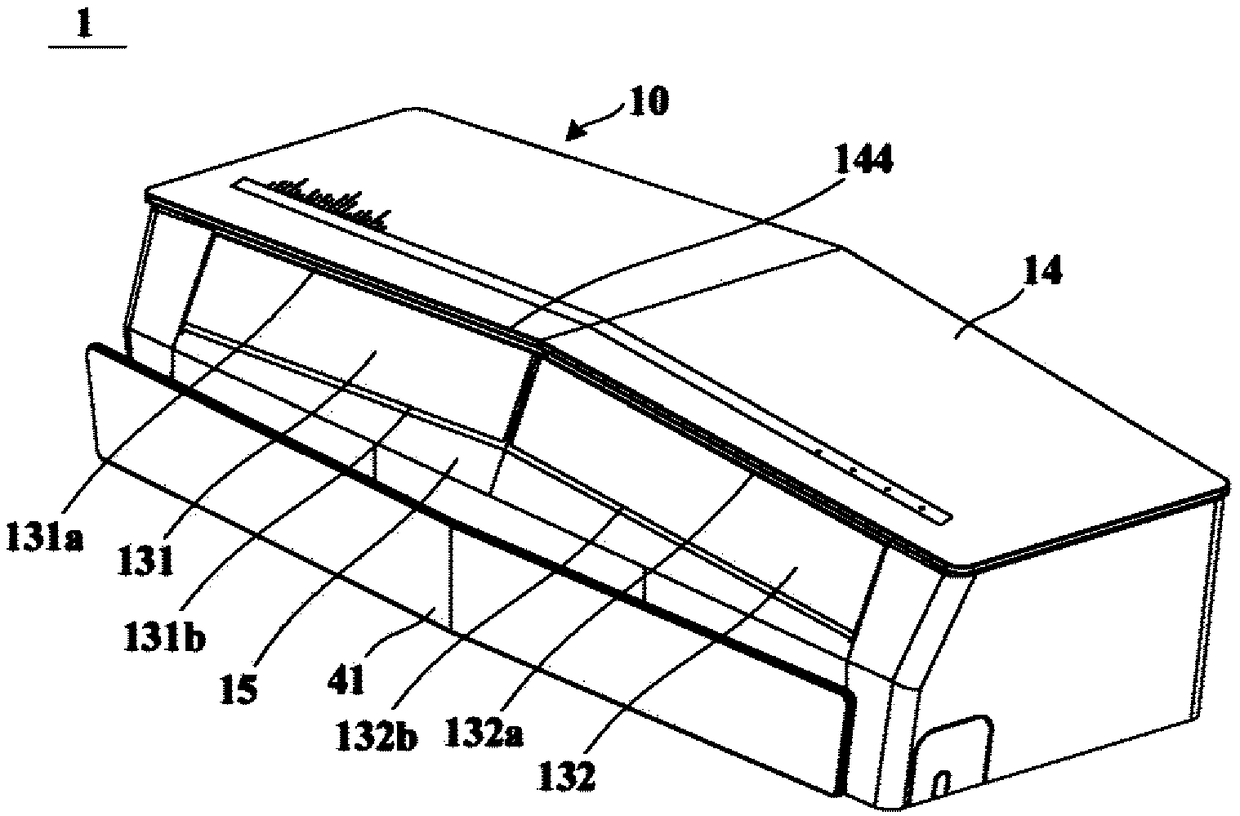

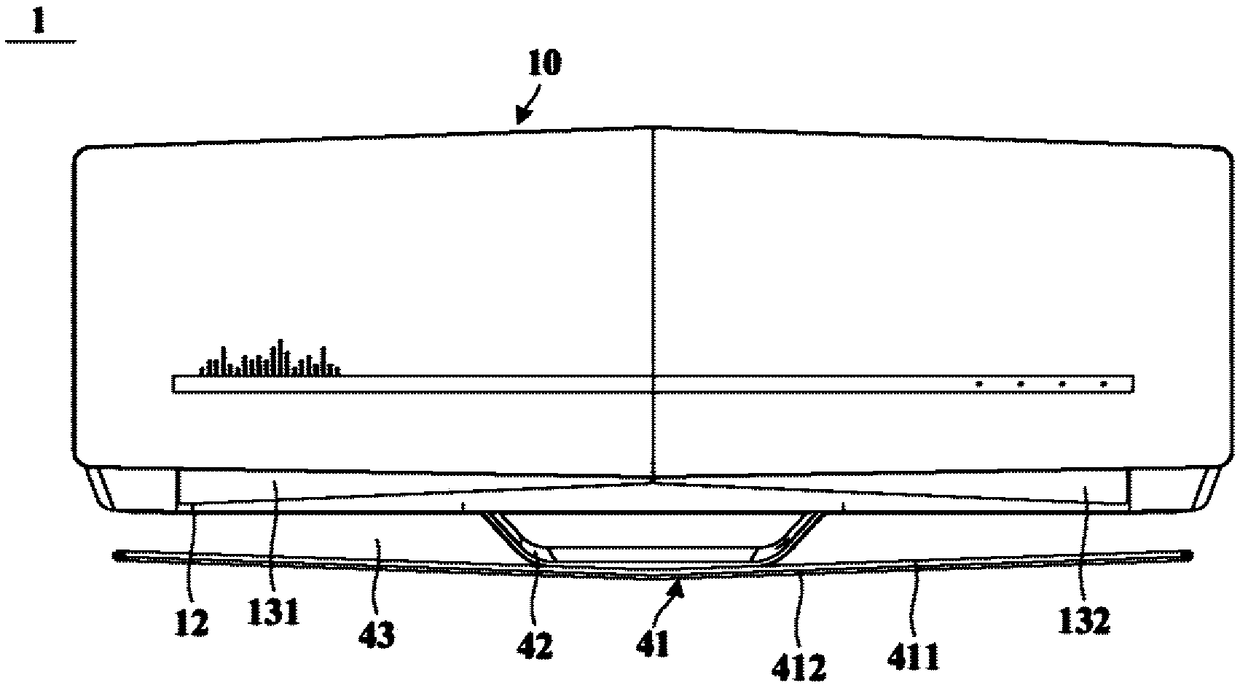

Wall mounted type air conditioner indoor unit

PendingCN108758828AMeet different needsImprove user experienceLighting and heating apparatusHeating and ventilation casings/coversVertical planeEngineering

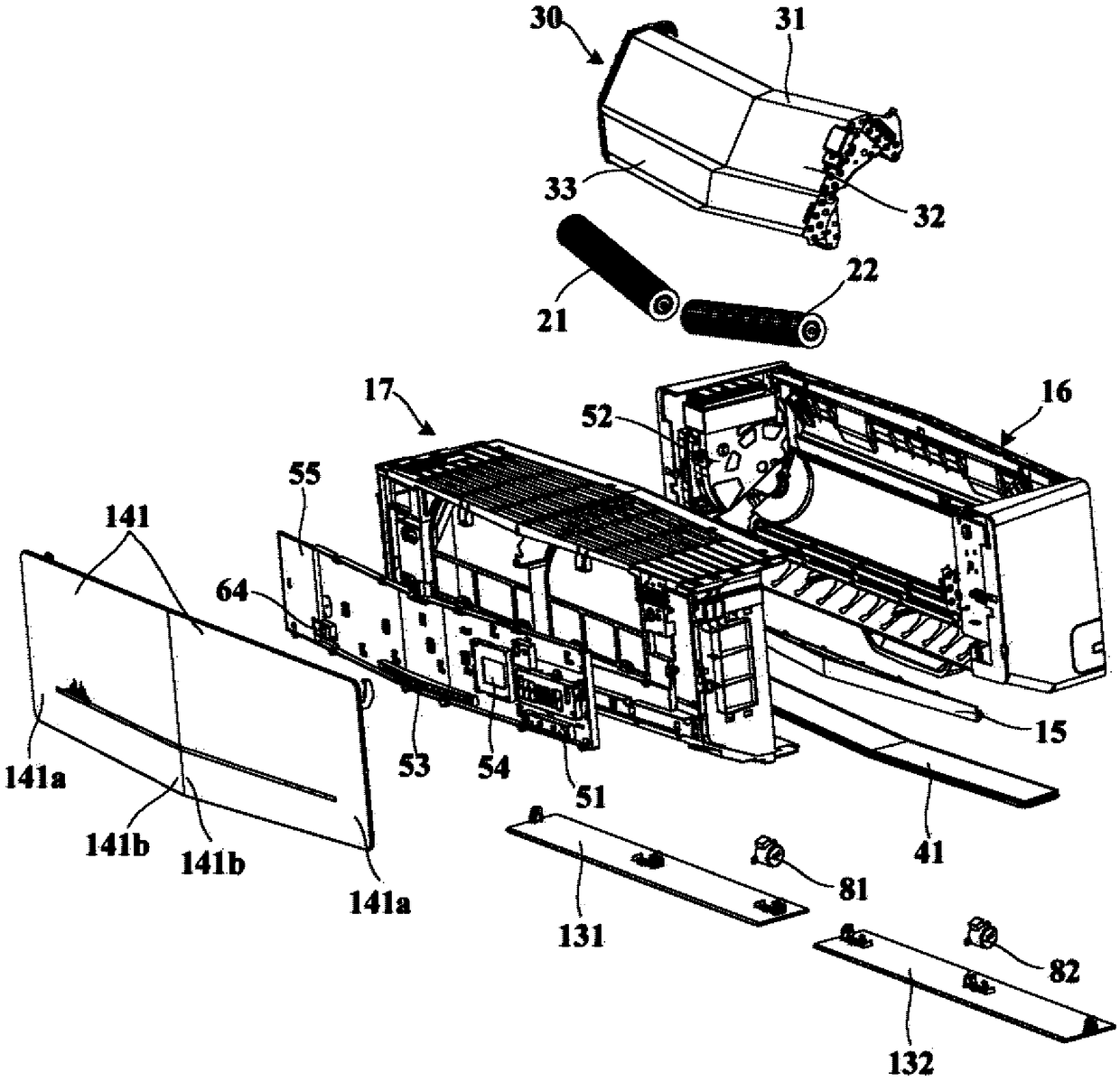

The invention relates to a wall mounted type air conditioner indoor unit which comprises a machine shell and two independent cross-flow fans. The machine shell is provided with an air inlet and an airoutlet extended in the transverse direction of the machine shell. The air outlet is provided with two independent air guide plates arranged side by side in the transverse direction, each air guide plate is arranged to be pivoted around a rotating shaft of the corresponding air guide plate in a controlled mode, the rotating shafts of the two air guide plates are obliquely extended upwards from thetwo ends in the transverse direction of the machine shell to the middle of the machine shell, and therefore the projections of the rotating shafts of the two air guide plates in a vertical plane perpendicular to the front-back direction form an inverted V shape which is inclined upwards gradually from the two ends in the transverse direction of the machine shell to the middle of the machine shell. The two independent cross-flow fans are arranged in the machine shell side by side in the transverse direction, each cross-flow fan is arranged to be rotated around a rotating shaft of the corresponding cross-flow fan in a controlled mode, the rotating shafts of the two cross-flow fans are obliquely extended forwards from the two ends in the transverse direction of the machine shell to the middle of the machine shell, and therefore the projections of the rotating shafts of the two cross-flow fans in the horizontal plane form a V shape which is inclined forwards gradually from the two ends inthe transverse direction of the machine shell to the middle of the machine shell.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Wall-mounted air conditioner indoor unit

PendingCN108692373AIncrease the lengthIncrease the effective heat transfer areaLighting and heating apparatusHeating and ventilation casings/coversControl mannerEngineering

The invention relates to a wall-mounted air conditioner indoor unit. The wall-mounted air conditioner indoor unit comprises a shell, and at least one cross-flow fan and evaporators arranged in the shell. The shell is provided with an air inlet and a strip-type air outlet which blows air indoors, wherein two independent air guide plates are arranged at the air outlet; each air guide plate is configured to pivot around the extension direction, parallel to the air outlet, of the air guide plate in a controlled manner, and the rotary shafts of the two air guide plates are collinear or parallel; the evaporator is arranged on the at least one cross-flow fan in a covering manner and comprises a first heat exchange section, a second exchange section and a third heat exchange section which are successively connected from back to front. The third heat exchange section is a V-shaped heat exchange section, which extends obliquely, deviated from the outer side direction of the at least one cross-flow fan gradually toward the middle of the shell from two transverse ends of the shell or is a curved surface heat exchange section, which protrudes out of the shell and extends in a bent manner, deviated from the outer side direction of the at least one cross-flow fan gradually toward the middle of the shell from two transverse ends of the shell. Dual zone air blowing of multiple modes is achieved, the effective heat exchange area of the evaporator is increased, the heat exchange efficiency is improved, the air supplementing capacity is increased, and the operating noise is reduced.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Wall-mounted air conditioner indoor unit

PendingCN108758827AMeet different needsImprove user experienceLighting and heating apparatusHeating and ventilation casings/coversEngineeringWall mount

The invention relates to a wall-mounted air conditioner indoor unit. The wall-mounted air conditioner indoor unit comprises a machine shell, two independent cross-flow fans and an evaporator; the machine shell is provide with an air inlet and an air outlet which extends in the transverse direction of the machine shell, and an air guide plate is arranged at the air outlet; the two independent cross-flow fans are transversely arranged in the machine shell in a side-by-side mode, and rotating shafts of the two cross-flow fans obliquely forwards extend from the transverse two ends of the machine shell to the middle of the machine shell correspondingly so as to enable the projection of the rotating shafts of the two cross-flow fans in the horizontal plane to form a V shape which is gradually obliquely forwards from the transverse two ends of the machine shell to the middle of the machine shell; the evaporator is arranged on the two cross-flow fans in a covering mode, and comprises a first heat exchange section, a second heat exchange section and a third heat exchange section which are sequentially connected from the back to the front, the first heat exchange section is located on the rear sides or the rear upper sides of the two cross-flow fans, the third heat exchange section is located on the front sides of the two cross-flow fans, and the first heat exchange section and the thirdheat exchange section are each a V-shaped heat exchange section which gradually obliquely forwards extends from the transverse two ends of the machine shell to the middle of the machine shell or a curved surface heat exchange section which gradually forwards protrudes and extends in a bending mode.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Wall-mounted indoor air conditioner

PendingCN108758825AMeet different needsImprove user experienceLighting and heating apparatusHeating and ventilation casings/coversEngineeringWall mount

The invention relates to a wall-mounted indoor air conditioner which comprises a machine shell and two independent cross-flow fans, wherein the machine shell is provided with an air inlet and an air outlet; the air outlet extends along the transverse direction of the machine shell; an air guide plate used for adjusting the opening-closing state and / or the air outlet direction of the air outlet isarranged at the air outlet; the cross-flow fans are arranged in the machine shell side by side; each air guide plate is configured to pivot on an own rotating shaft under control, and the rotating shafts of the two cross-flow fans correspondingly extend in an inclined forward manner from the two transverse ends to the middle of the machine shell, so that the V-shaped, which are gradually inclinedforward from the two transverse ends to the middle of the machine shell, of the rotating shafts of the two cross-flow fans in a horizontal plane can be formed; and accordingly, the air outlet direction of each cross-flow fan can face a front position below the transverse outer side of the machine shell, the restriction of the usual arrangement mode of a cross-flow fan in the prior art to the air supply angle of the cross-flow fan can be broken through, the air supply scope of the wall-mounted indoor air conditioner can be expanded, and a plurality of modes of double-area air supply can be achieved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Wall-mounted air conditioner indoor unit

PendingCN108758829AImprove user experienceIncrease the wide angle of air supplyLighting and heating apparatusHeating and ventilation casings/coversEvaporatorSurface heat

The invention relates to a wall-mounted air conditioner indoor unit. The wall-mounted air conditioner indoor unit comprises a machine shell, at least one cross-flow fan and an evaporator; the machineshell is provided with an air inlet and an air outlet, two independent air guide plates are arranged at the air outlet, and each air guide plate is configured to be controlled to be pivoted around a rotating shaft of the corresponding air guide plate; the at least one cross-flow fan and the evaporator are arranged in the machine shell, the evaporator is arranged on the at least one cross-flow fanin a covering mode, and comprises a first heat exchange section, a second heat exchange section and a third heat exchange section which are sequentially connected from back to front, and the third heat exchange section is a V-shaped heat exchange section which extends gradually obliquely in the direction opposite to the outer side of the at least one cross-flow fan from the transverse two ends ofthe machine shell to the middle of the machine shell or a curved surface heat exchange section which gradually protrudes and extends in a bending mode in the direction towards the outer side. Rotatingshafts of the two air guide plates extend upwards from the two transverse side parts of the machine shell to the middle part of the machine shell correspondingly so as to enable the projection of therotating shafts of the two air guide plates in the vertical plane perpendicular to the front and back direction to form an inverted V shape which is gradually obliquely upwards from the transverse two ends of the machine shell to the middle of the machine shell.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Wall mounted type air conditioner indoor unit

PendingCN108758831AMeet different needsImprove user experienceLighting and heating apparatusHeating and ventilation casings/coversEngineeringControl mode

The invention relates to a wall mounted type air conditioner indoor unit which comprises a machine shell, two independent cross-flow fans and an evaporator. The machine shell is provided with an air inlet and an air outlet extended in the transverse direction of the machine shell. The air outlet is provided with two independent air guide plates, and each air guide plate is arranged to be pivoted around a rotating shaft, parallel to the extension direction of the air outlet, of the corresponding air guide plate in a controlled mode. Each cross-flow fan is arranged to be rotated around a rotating shaft of the corresponding cross-flow fan in a controlled mode. The rotating shafts of the two cross-flow fans are obliquely extended forwards from the two ends in the transverse direction to the middle, and therefore the projections of the rotating shafts of the two cross-flow fans in the horizontal plane form a V shape which is inclined forwards gradually from the two ends in the transverse direction of the machine shell to the middle of the machine shell. The evaporator covers the two cross-flow fans, and comprises a first heat exchange section, a second exchange section and a third heatexchange section which are connected in sequence from back to front, and both the first heat exchange section and the third heat exchange section are V-shaped heat exchange sections which are obliquely extended forwards gradually from the two ends in the transverse direction of the machine shell to the middle of the machine shell or curved surface heat exchange sections which are protruded, bent and extended forwards gradually.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Glass blind hole machining method

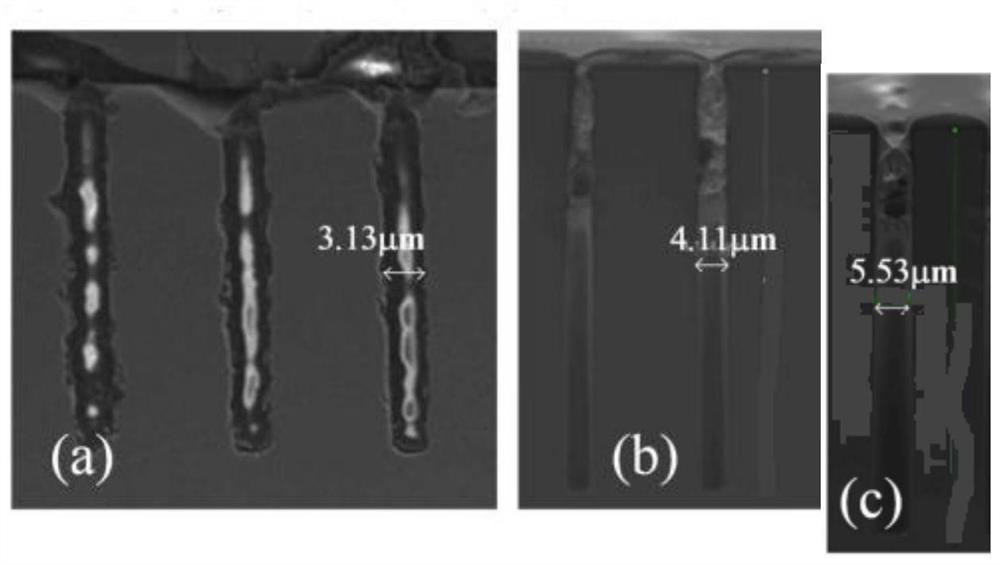

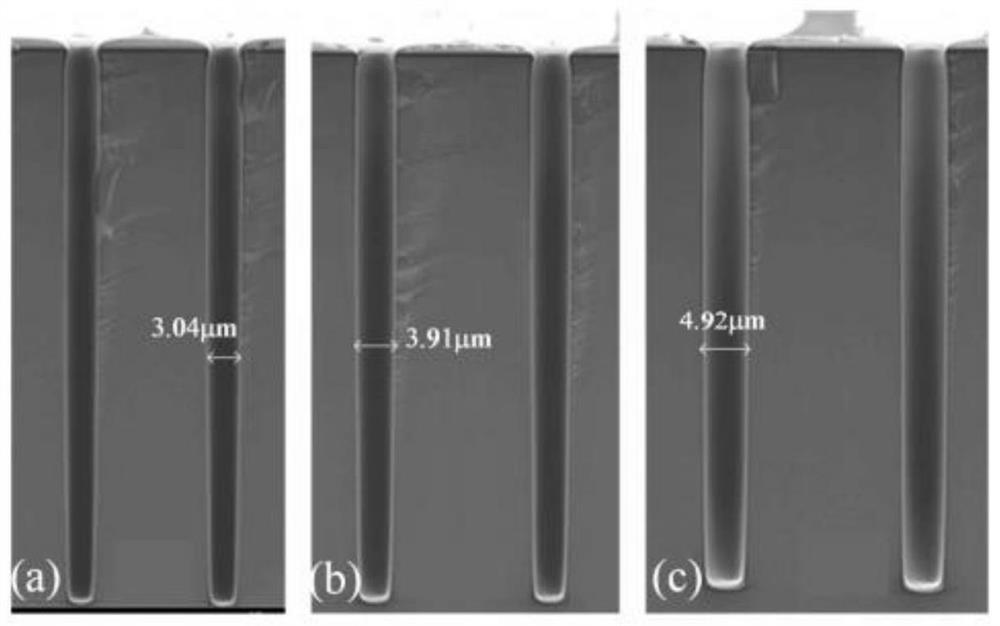

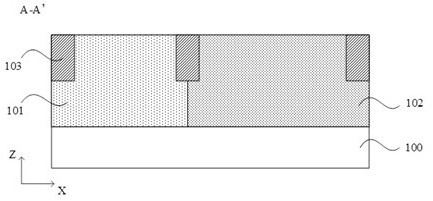

ActiveCN111816608AGood adhesionImprove deposition qualitySemiconductor/solid-state device detailsSolid-state devicesEtchingMiniaturization

The invention provides a glass blind hole machining method. The glass blind hole machining method comprises the steps of: a, carrying out deep hole etching; b, depositing an adhesion layer on the sidewalls of deep holes: b1, dispensing a high polymer solution on the surface of a glass substrate to ensure that the high polymer solution covers the surface of the glass substrate; b2, transferring the glass substrate to an environment of which the pressure is lower than atmospheric pressure, and standing the glass substrate so that the deep holes are filled with the polymer solution; b3, fixing the glass substrate to a rotary disc, and driving the rotary disc to rotate to thrown away the high polymer solution on the surface of the glass substrate and in the deep holes, wherein the center of the glass substrate deviates from the rotation center of the rotary disc; b4, drying to cure the residual high polymer solution on the surface of the glass substrate and the side walls of the deep holes to form a high polymer adhesive film; c, depositing a seed layer on the side walls; d, filling copper in the deep holes; and e, conducting surface CMP and RDL wiring manufacturing. The TSV preparedby adopting the glass blind hole machining method has high thermal-mechanical reliability and excellent electrical properties, can be used for processing deep holes with the aperture of 3 microns andthe depth of 45 microns, and conforms to the development trend of TSV miniaturization.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

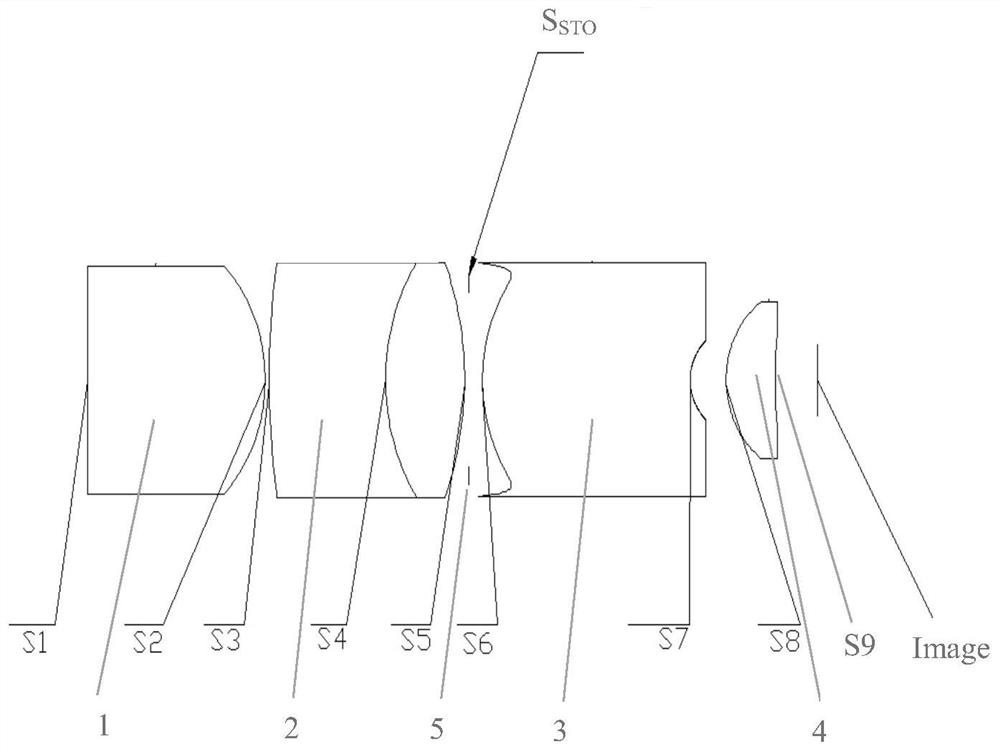

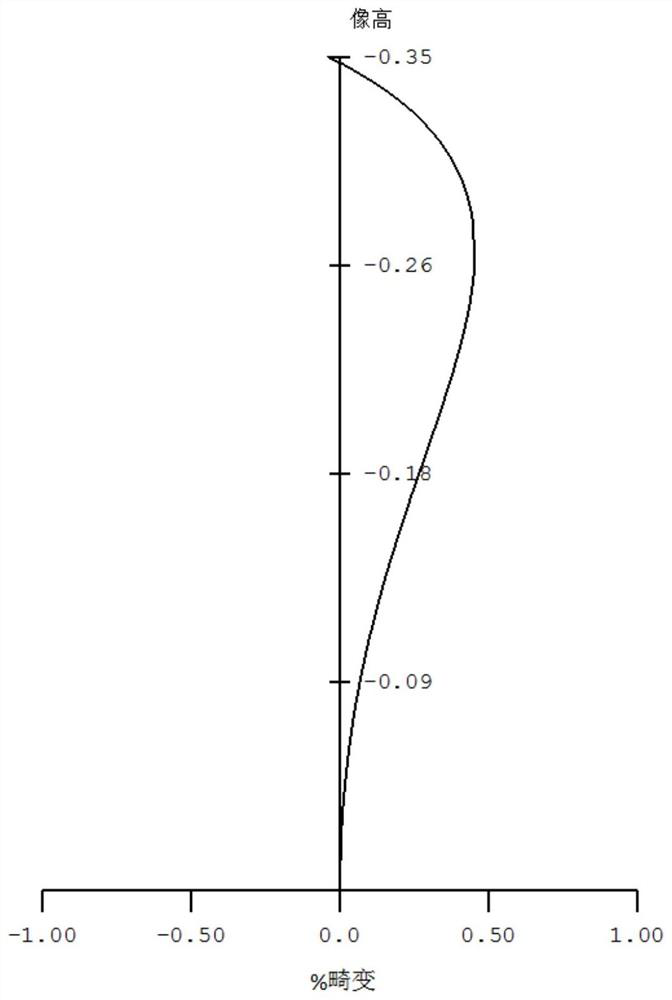

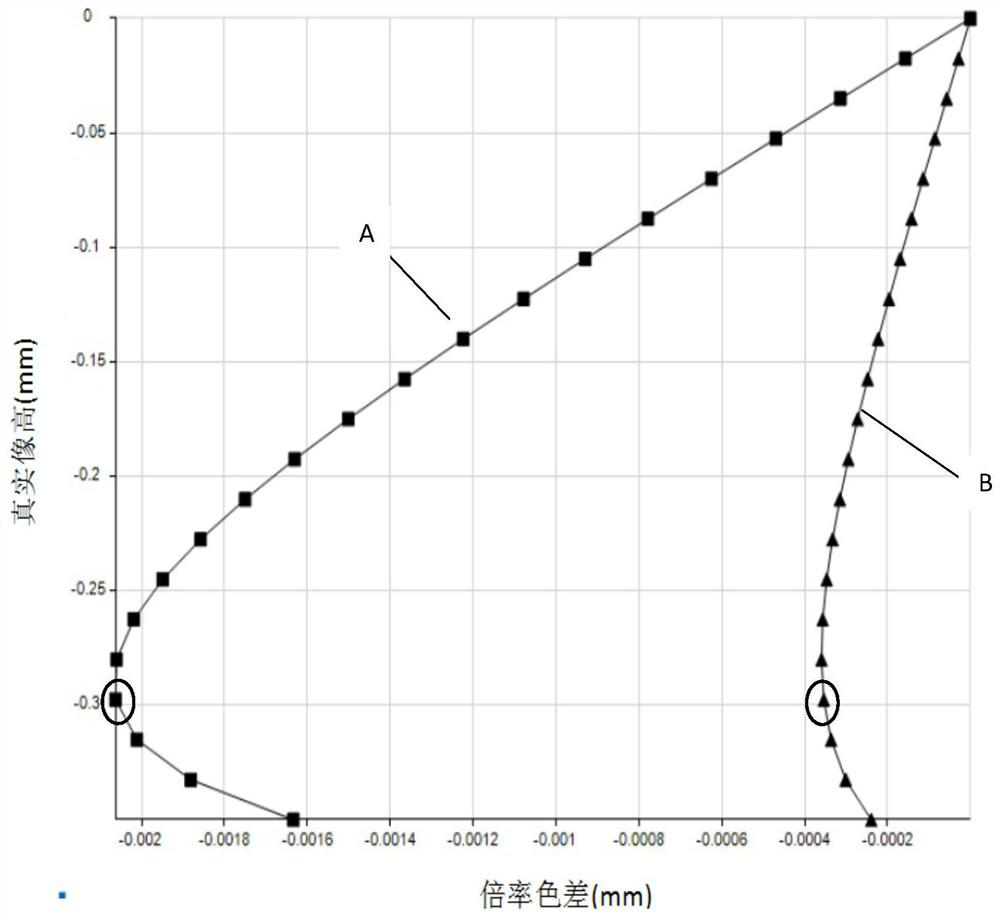

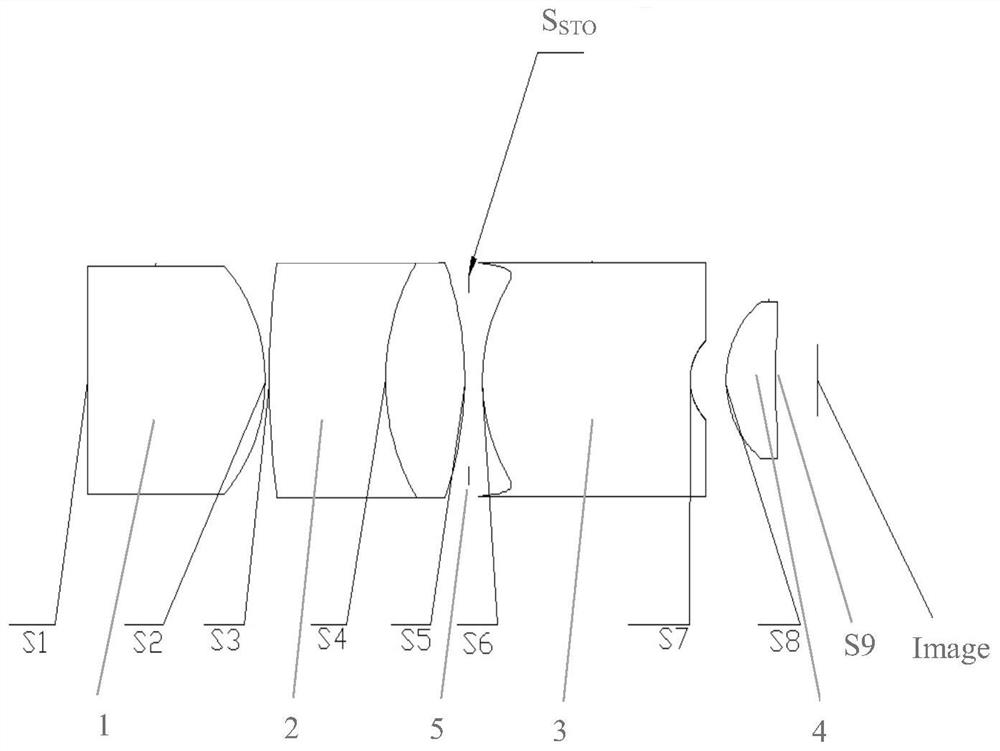

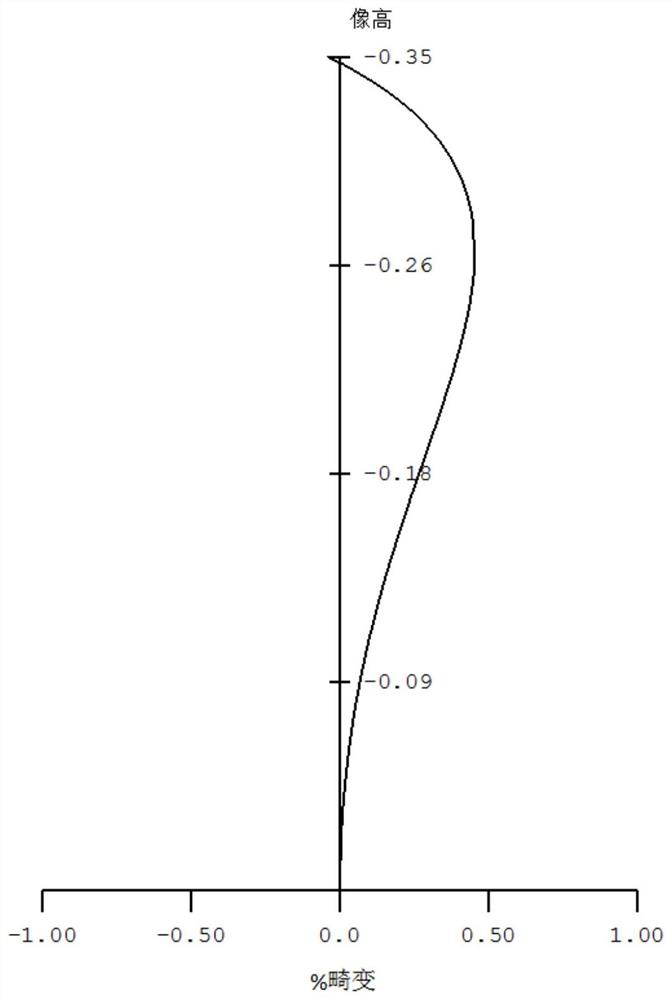

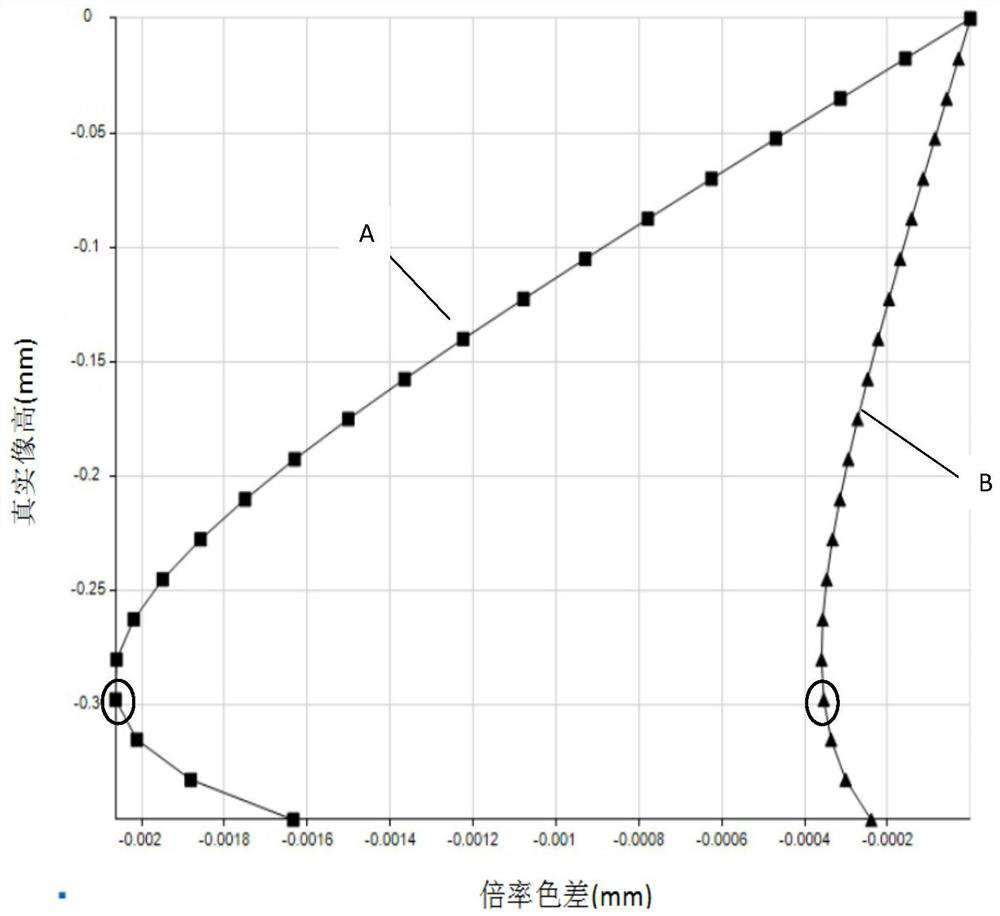

Immersion type high-resolution small-caliber optical fiber microscope objective

ActiveCN111624735AReduce Tolerance SensitivityIn line with the development trend of miniaturizationSurgeryEndoscopesImaging qualityMicroscope objective

The invention discloses an immersion type high-resolution small-caliber optical fiber microscope objective, which belongs to the technical field of optical lenses. The microscope objective comprises afirst lens element, a second lens element, a third lens element and a fourth lens element which are sequentially arranged from an object plane to an image plane; the first lens element is a sphericalpositive lens; the second lens element is a spherical doublet lens and comprises a first lens and a second lens which are arranged in sequence, and the first lens is a negative lens; the second lensis a positive lens; the third lens element is a negative lens; the fourth lens element is a positive lens; the focal length of each lens element satisfies the following relational expression: 0.6 < f1 / f < 0.9, -3.1 < f21 / f < -1.3, 0.512 < f22 / f < 1.892, 1.49 < f2 / f < 2.5, -3.6 < f3 / f < -2.4, and 0.5 < f4 / f < 0.7. The objective of the invention is to solve the technical problems that the optical aperture of a conventional optical fiber microscope objective is not small enough, and small distortion cannot be realized while the imaging quality is ensured.

Owner:熊艳辉 +1

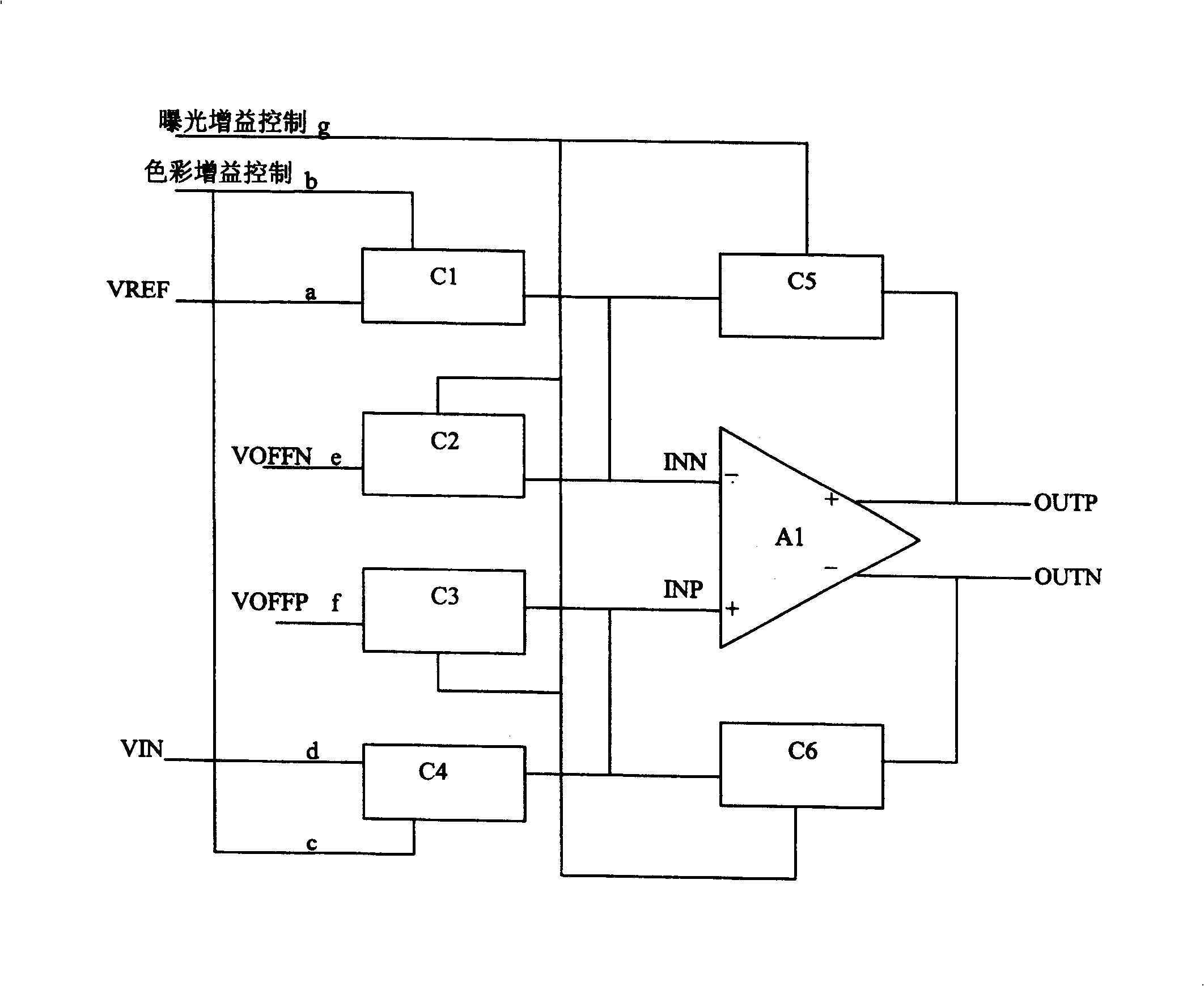

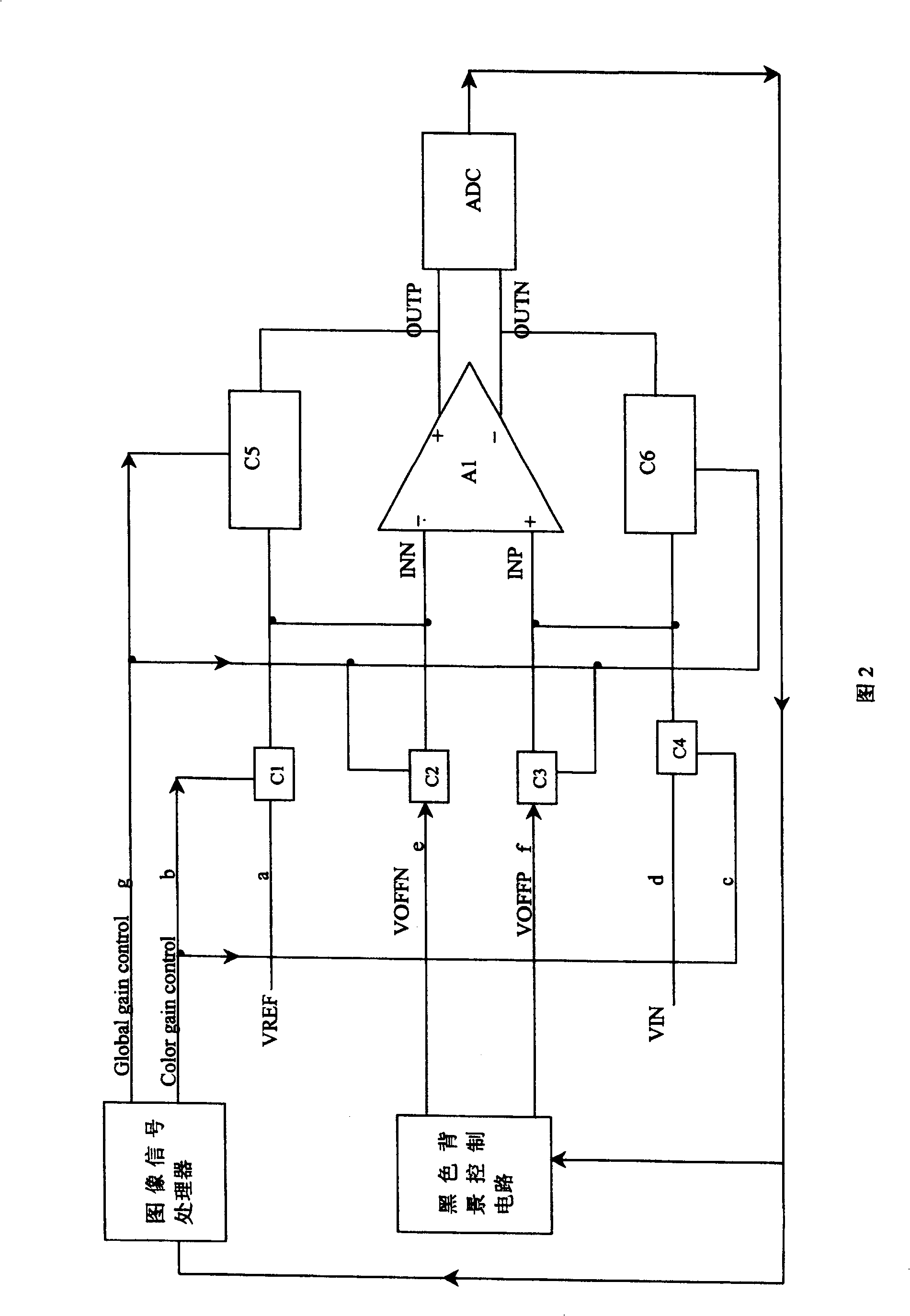

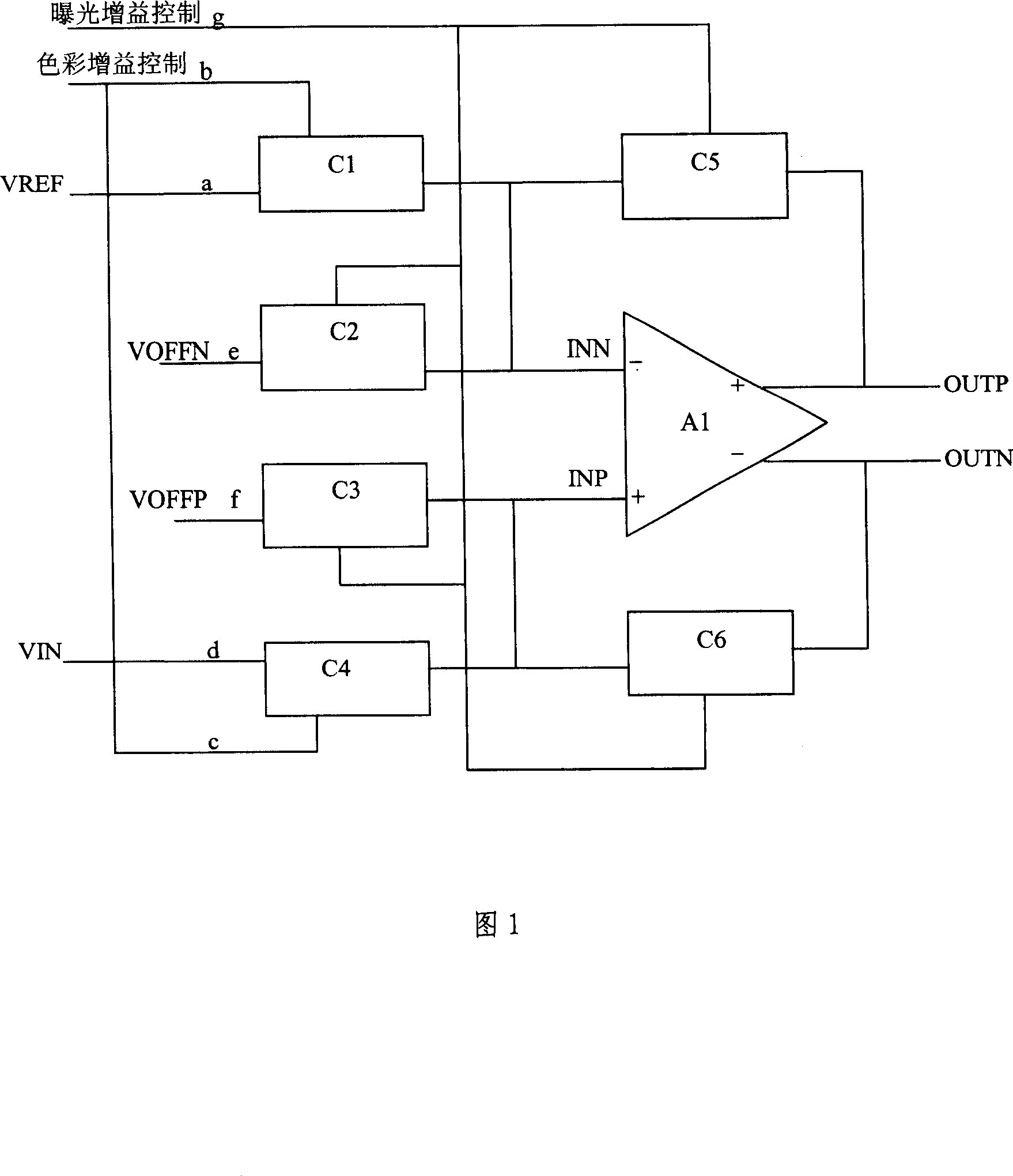

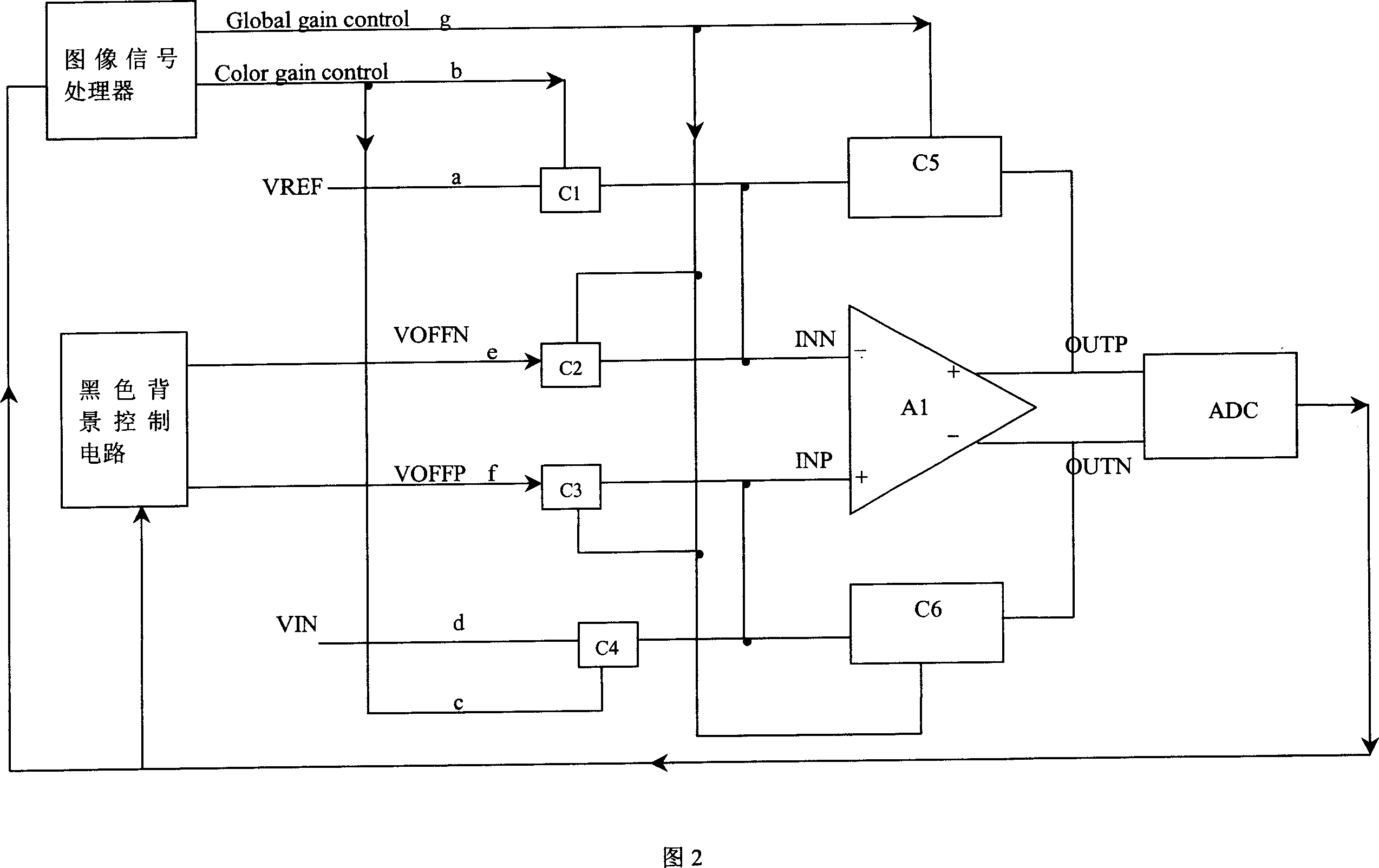

Signal processing circuit of analog image for CMOS image sensor

ActiveCN100444613CSimple structureReduce volumeTelevision system detailsColor television detailsCMOS sensorCapacitance

The invention discloses an analog image signal processing circuit for a CMOS image sensor, which includes a differential operational amplifier, an input stage capacitor and an output stage capacitor. The input stage capacitor includes a first positive input stage switched capacitor array and a first negative input stage. Switched capacitor array; the input analog image signal of the first positive input switched capacitor array, the control terminal is connected to the color gain control signal terminal, and the output terminal is coupled to the input positive terminal of the differential operational amplifier; the input reference of the first negative input switched capacitor array Level signal, the control terminal is connected to the color gain control signal terminal, and the output terminal is coupled to the input negative terminal of the differential operational amplifier; the output stage capacitor is connected between the output terminal and the input terminal of the differential operational amplifier. The present invention uses one circuit to realize two or more control functions. On the premise of ensuring the imaging effect, the circuit structure is simplified, the size of the CMOS image sensor chip is reduced, the cost is reduced, and it is in line with the development trend of product miniaturization.

Owner:BYD SEMICON CO LTD

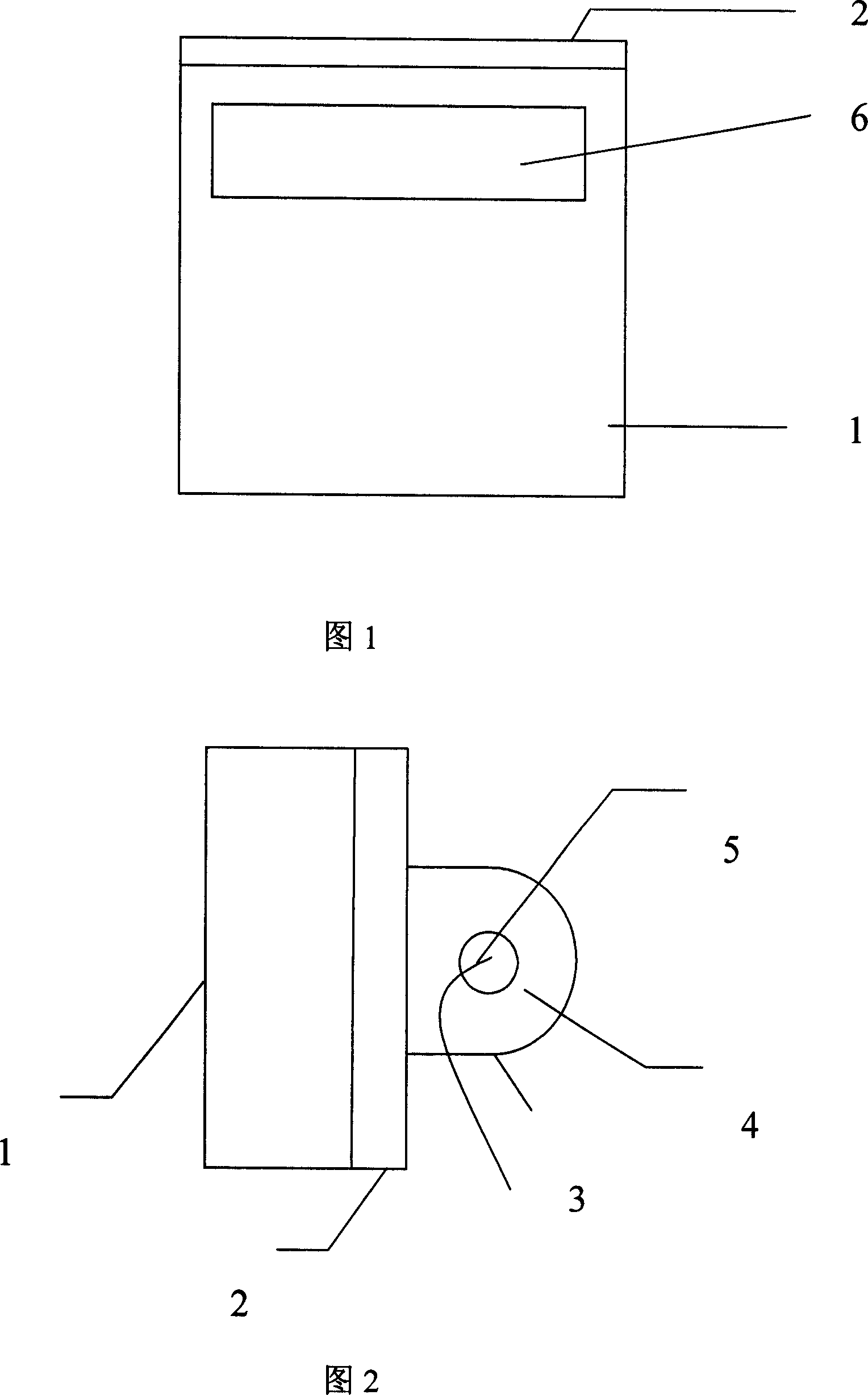

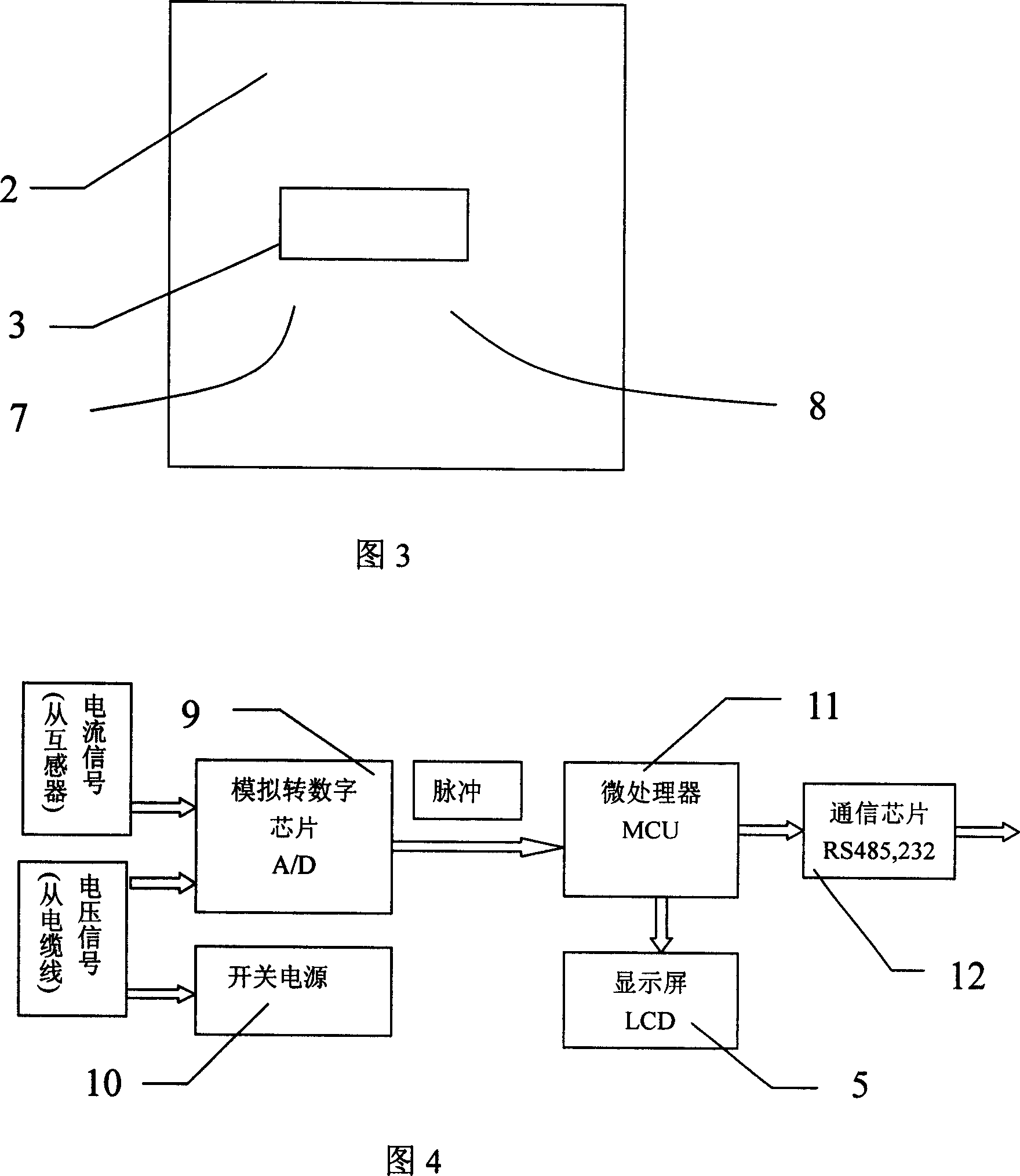

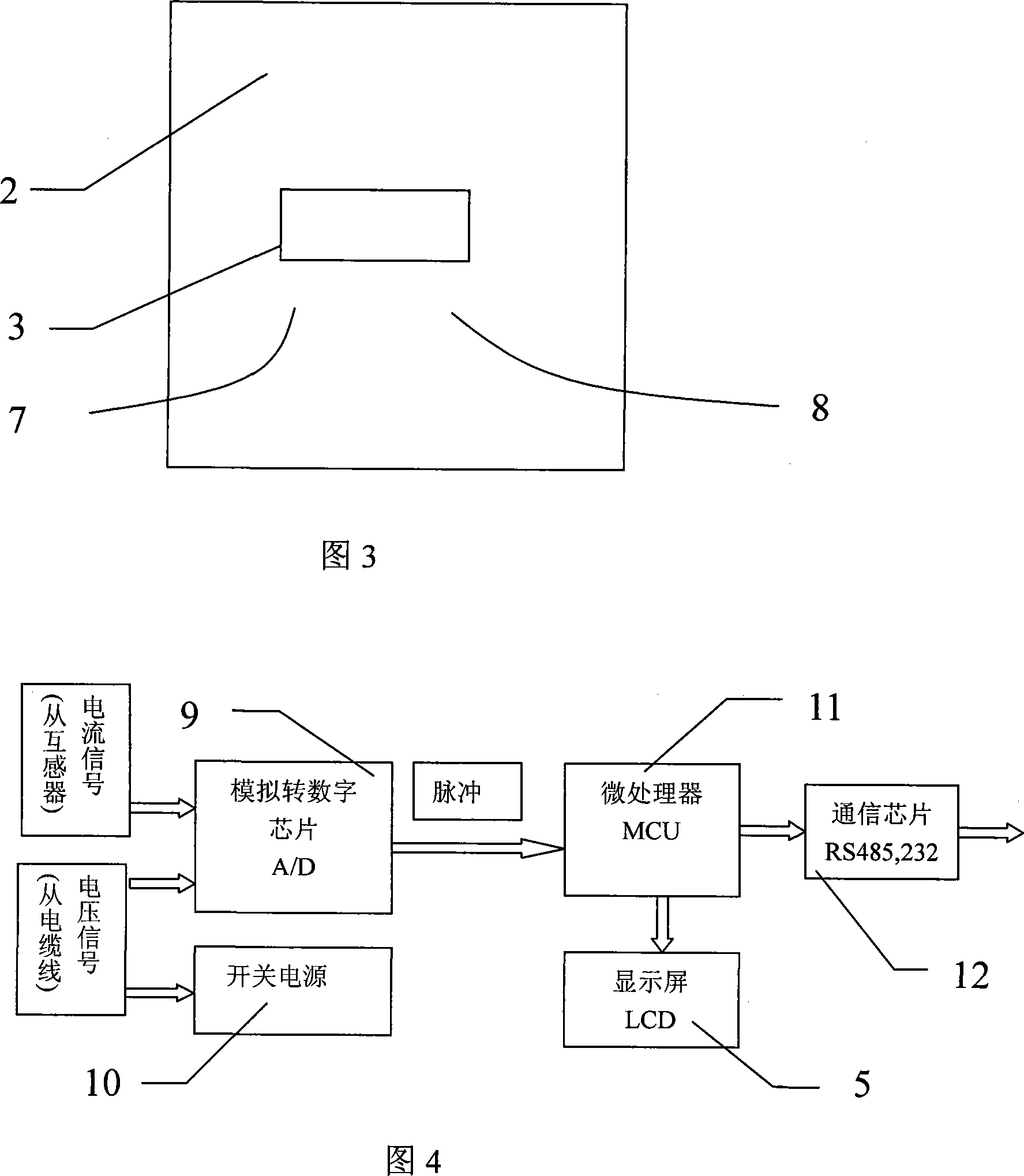

Contactless watt-hour meter

InactiveCN101000364AFire Hazard PreventionCompact structureTime integral measurementContact freeInductor

A watt-hour meter of contact-free type is prepared as arranging display screen at front surface of shell; setting A / D chip, switch power supply, microprocessor and communication chip in shell; setting pulse line, power supply line and inductor protective case on shell base then setting inductor with circular hole in said case.

Owner:白在铭

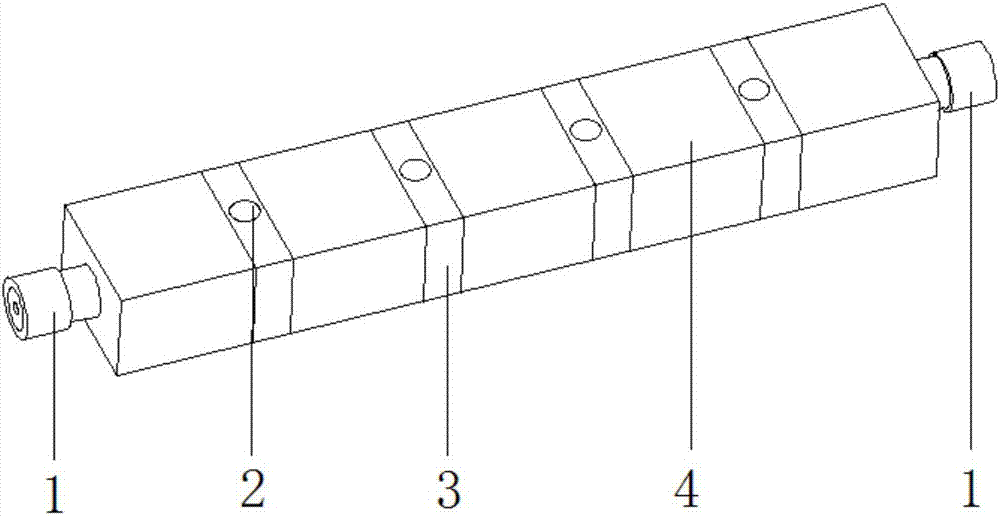

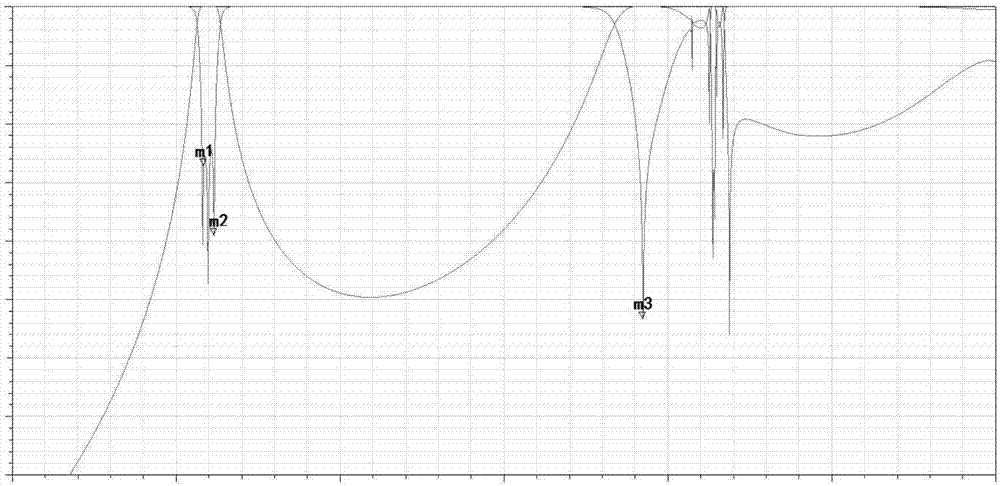

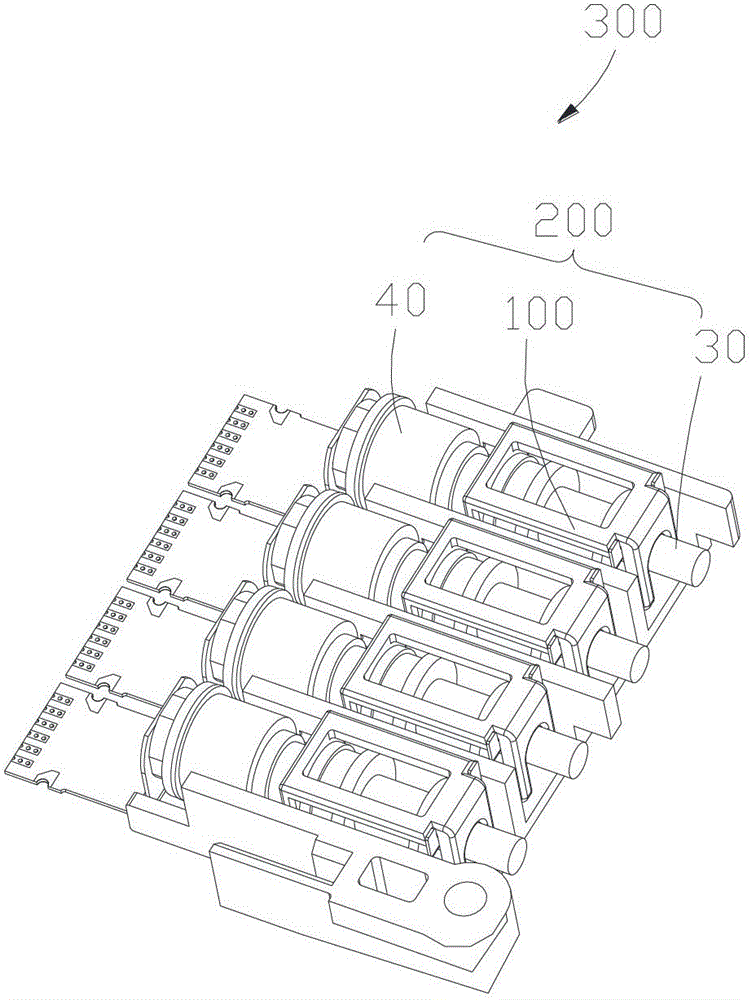

Dielectric waveguide filter

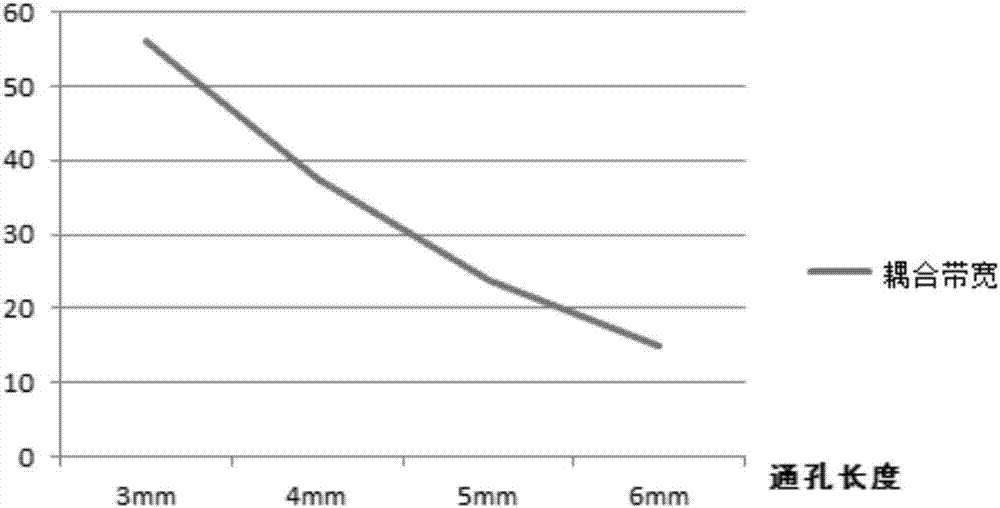

InactiveCN107069157AAdjust the amount of couplingHigh strengthWaveguide type devicesDielectricCoupling

The invention provides a dielectric waveguide filter, which solves the problem that an existing dielectric waveguide filter is poor in strength due to structure thereof. The dielectric waveguide filter comprises a filter body. The filter body is provided with a radio-frequency connector and a filter dielectric block. The filter dielectric block comprises a plurality of dielectric single cavities and a plurality of coupling windows. The plurality of dielectric single cavities are connected in a head-to-tail manner in sequence through the coupling windows. Each coupling window is provided with more than one sensitive through hole in the middle. The dielectric waveguide filter can effectively adjust coupling amount of each coupling window to enable the strength of each coupling window to be higher, so that the overall strength of the dielectric waveguide filter is allowed to be higher; the structural strength is more reliable; processing process is allowed to be simpler and more convenient; the dielectric waveguide filter can better meet requirements of low insertion loss, high suppression and high power and the like of the filter, and meanwhile, meets development trend of miniaturization of the filter; and filter signals can be limited within the filter well and are isolated from the external space.

Owner:SICHUAN TAOGUANG COMM

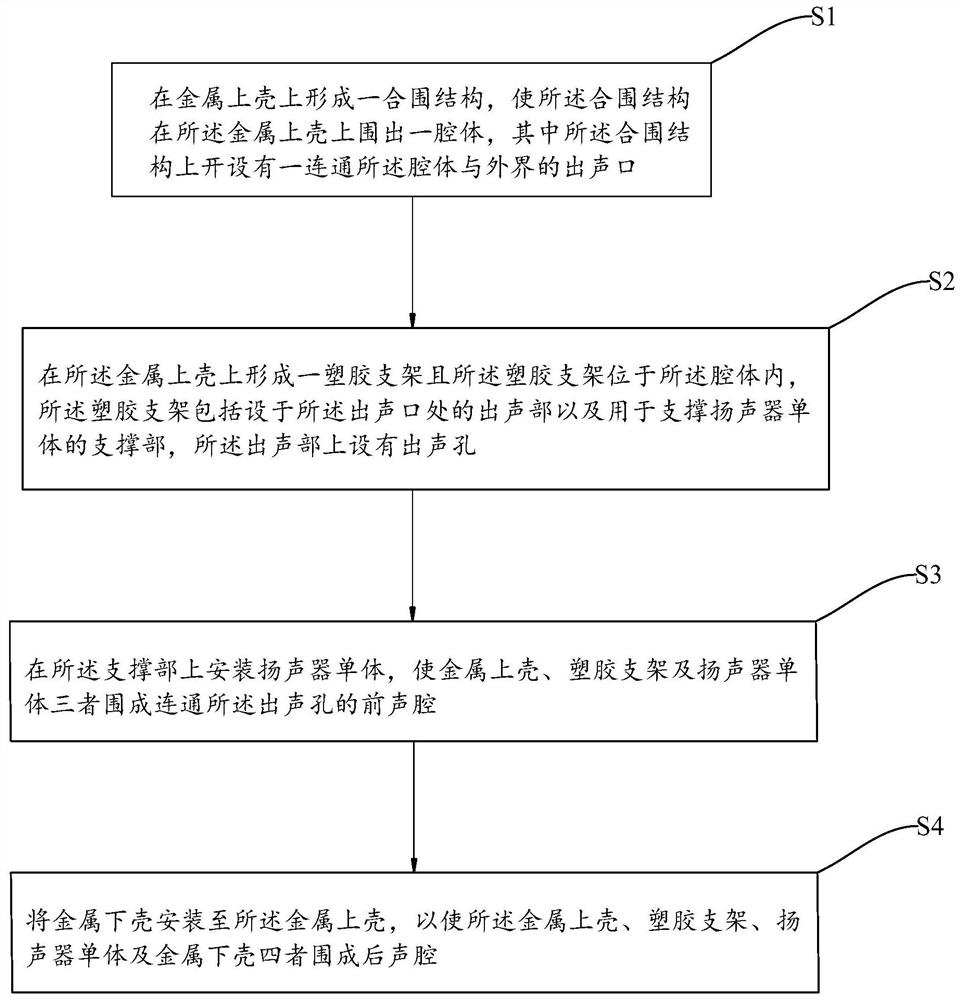

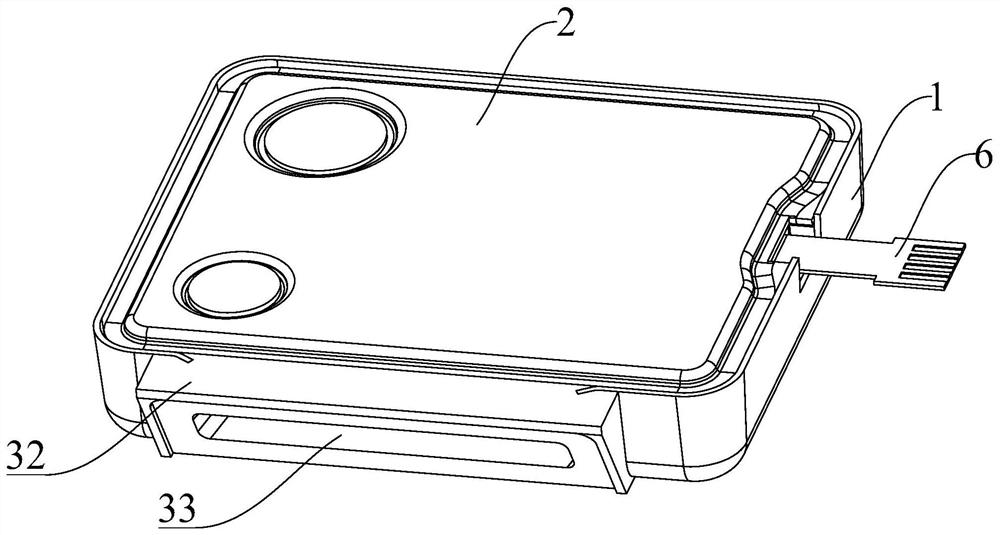

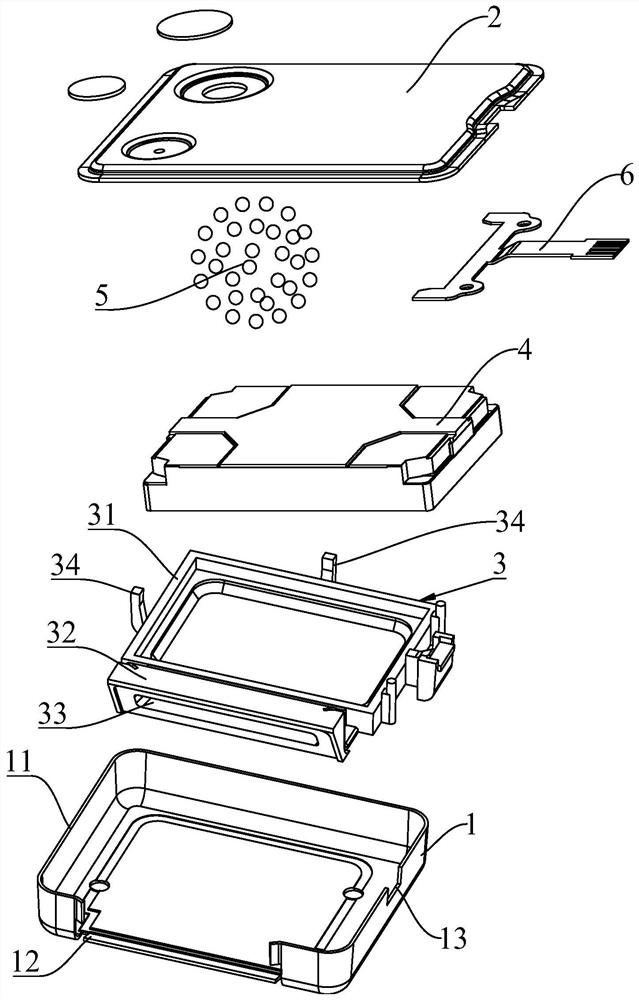

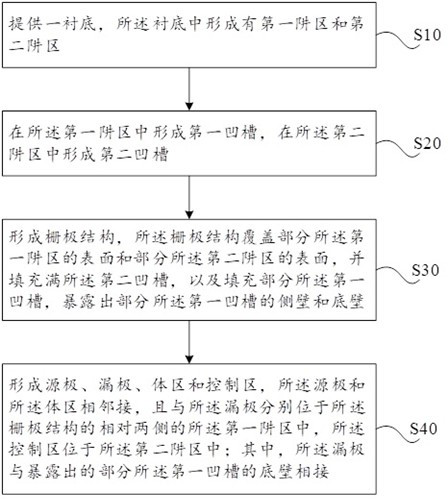

Preparation method of loudspeaker module

The invention discloses a preparation method of a loudspeaker module, which comprises the following steps: S1, forming an enclosing structure on a metal upper shell, so that the enclosing structure encloses a cavity on the metal upper shell, and the enclosing structure is provided with a sound outlet for communicating the cavity with the outside; S2, forming a plastic support on the metal upper shell and located in the cavity, wherein the plastic support comprises a sound outlet part arranged at the sound outlet and a supporting part used for supporting the loudspeaker single body, and a sound outlet hole is formed in the sound outlet part; S3, installing a loudspeaker monomer on the supporting part, and enabling the metal upper shell, the plastic support and the loudspeaker monomer to form a front sound cavity communicated with the sound outlet hole in an enclosing manner; and S4, installing the metal lower shell on the metal upper shell, so that the metal upper shell, the plastic support, the loudspeaker monomer and the metal lower shell form a rear sound cavity. The plastic support is accommodated by the metal upper shell and the metal lower shell, maximization of the cavity space of the front vocal cavity and the rear vocal cavity is realized in a limited space, and improvement of the cavity performance is facilitated.

Owner:SHENZHEN SUNWAY ACOUSTICS TECH CO LTD

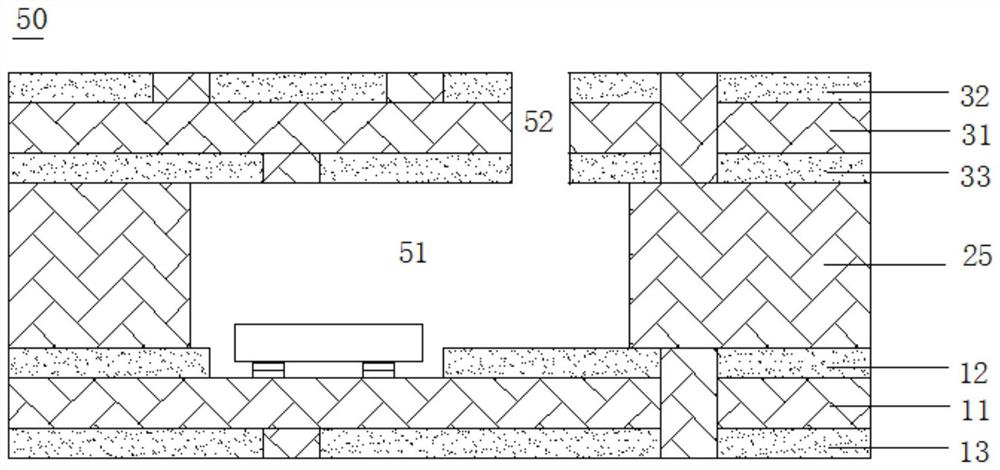

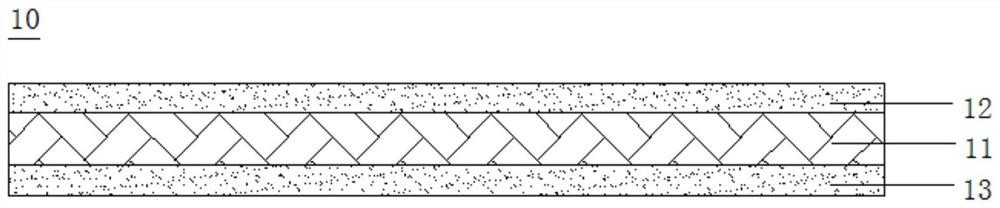

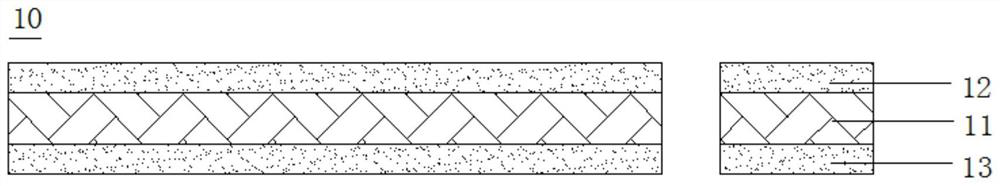

MEMS built-in chip packaging carrier and manufacturing process thereof

PendingCN114368726AImprove alignmentReduce distractionsTelevision system detailsImpedence networksSurface mountingEngineering physics

The invention relates to an MEMS built-in chip packaging carrier plate and a manufacturing process thereof, and the process comprises the following steps: preparing three core plates, namely a first core plate, a second core plate and a third core plate, and drilling and filling holes in the first core plate; an inner layer circuit of the first core board; sMT surface mounting is carried out; etching a second core plate and pressing a film; grooving the film plate; drilling and hole filling of the third core board; an inner layer circuit of the third core board; pressing: pressing the first core plate, the film plate and the third core plate together; and opening the cover. According to the packaging substrate, the function of a built-in chip is achieved, the size of the back cavity is increased under the condition that the size of a device is not increased, the sensitivity and the signal-to-noise ratio of a product are improved, and the packaging substrate conforms to the development trend of device miniaturization.

Owner:JIANGSU PROVISION ELECTRONICS CO LTD

Signal processing circuit of analog image for CMOS image sensor

ActiveCN1992788ASimple structureReduce volumeTelevision system detailsColor television detailsCMOS sensorCapacitance

The invention relates to an analogue image signal processing circuit used in CMOS image sensor, wherein it comprises differential amplifier, input capacitor, and output capacitor; the input capacitor comprises the first positive input switch capacitor array and the first passive switch capacitor array; the first positive array inputs analogue image signal; the controller is connected to the color gain control signal end; the output end is connected to the color gain control signal end; the output is coupled to the positive input of differential amplifier; the output is coupled to the passive input of differential amplifier; the output capacitor is connected between the output and input of differential amplifier / the invention uses one circuit to realize at least two control functions, to reduce the volume of CMOS sensor and cost.

Owner:BYD SEMICON CO LTD

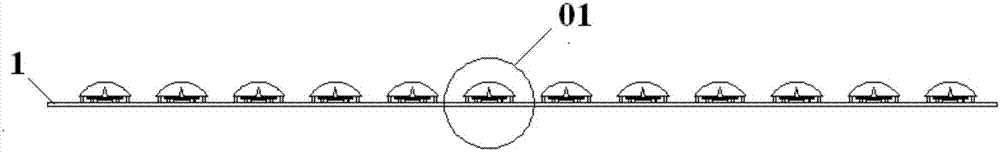

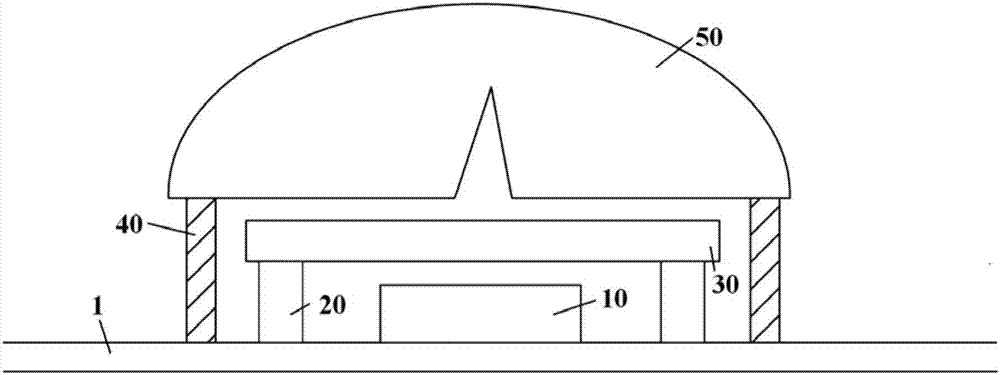

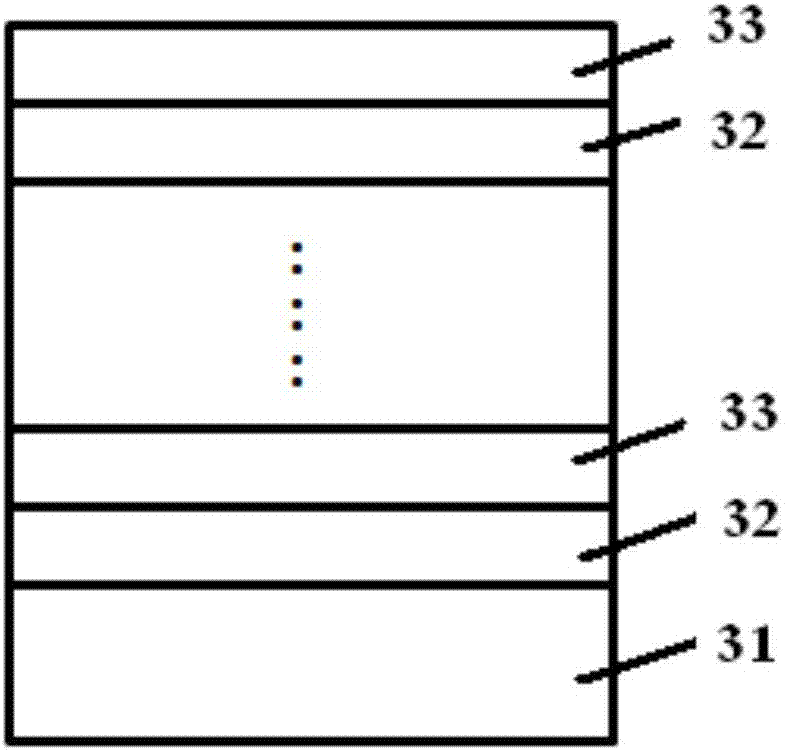

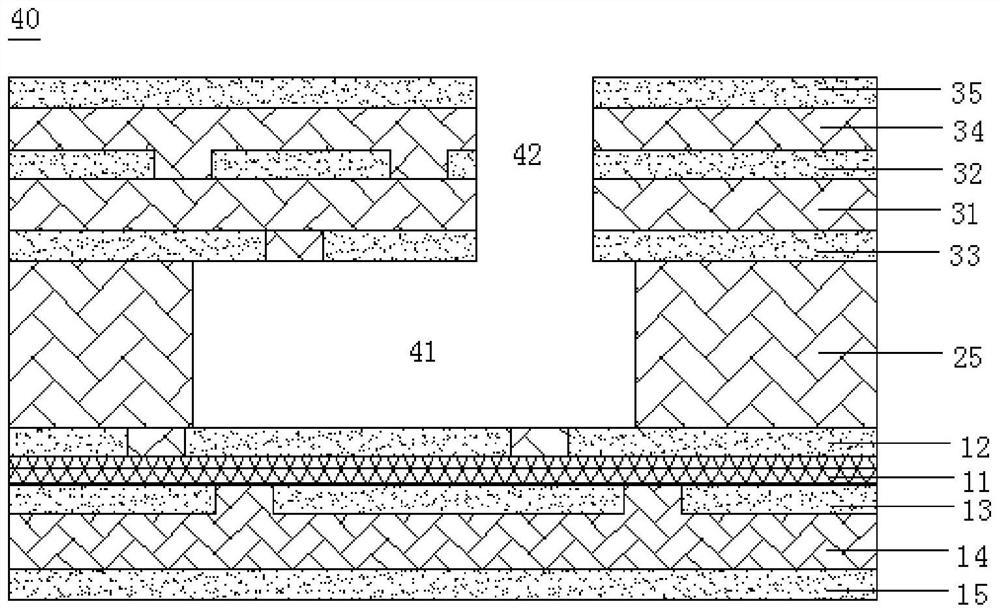

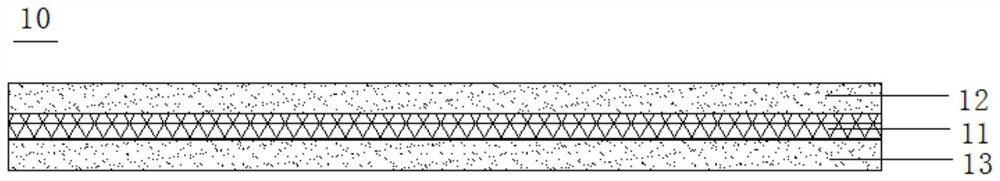

LED device and display device comprising same

PendingCN107305887AHighly integratedIn line with the development trend of miniaturizationSolid-state devicesSemiconductor devicesDisplay deviceMiniaturization

The invention provides an LED device and a display device comprising the same. The LED device comprises a printed circuit board (PCB) and a plurality of LEDs, wherein the plurality of LEDs are arranged on a surface of the PCB, each LED comprises an LED chip, an optical filter and a lens, the LED chip is arranged on the surface of the PCB, the optical filter is arranged at one side, far away from the PCB, of the LED chip and comprises a substrate layer and a filtering film, the substrate layer is arranged near to the LED chip, the filtering film is arranged at one side, far away from the LED chip, of the substrate layer, and the lens is arranged at one side, far away from the LED chip, of the optical filter. The optical filter is arranged in the LED, the comprehensive integration of a backlight module of the display device is improved, and the development trend of device size miniaturization is met.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Wall-mounted air conditioner indoor unit

PendingCN108758823AIncrease the lengthIncrease the effective heat transfer areaLighting and heating apparatusHeating and ventilation casings/coversEngineeringWall mount

The invention discloses a wall-mounted air conditioner indoor unit. The wall-mounted air conditioner indoor unit comprises a shell, a cross-flow fan and an evaporator; the shell is provided with an air inlet and an air outlet, and an air guide plate which is used for adjusting the opening and closing states and / or the air outlet direction of the air outlet is formed in the air outlet; the cross-flow fan and the evaporator are arranged in the machine shell; the evaporator is arranged on the cross-flow fan in a covered mode, and comprises a first heat exchange section, a second heat exchange section and a third heat exchange section which are sequentially connected with one another from the back to the front, and the third heat exchange section is located on the front side of the cross-flowfan; and the third heat exchange section is a V-shaped heat exchange section which is gradually inclined forwards and extends from the transverse two ends of the machine shell to the middle of the machine shell so as to form a triangular space between the third heat exchange section and the cross-flow fan, or, the third heat exchange section is a curved surface heat exchange section which gradually protrudes, is curved and extends from the transverse two ends of the machine shell to the middle of the machine shell so as to form an arch space between the third heat exchange section and the cross-flow fan. According to the wall-mounted air conditioner indoor unit, the effective heat exchange area of an evaporator is expanded, the heat exchange efficiency is improved, the air supplement amount is increased, and the operation noise is reduced.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Non-contact electricity meter

InactiveCN101089636AFire Hazard PreventionCompact structureElectrical measurementsEngineeringInductor

An electricity meter with no contact is prepared as arranging display screen at front surface of shell body; setting A / D conversion chip, switch power supply, microprocessor and communication chip in shell body; setting pulse line, power supply line and protection cover of mutual inductor on base plate of shell body and arranging inductor with ring shaped hole in said protection cover.

Owner:白在铭

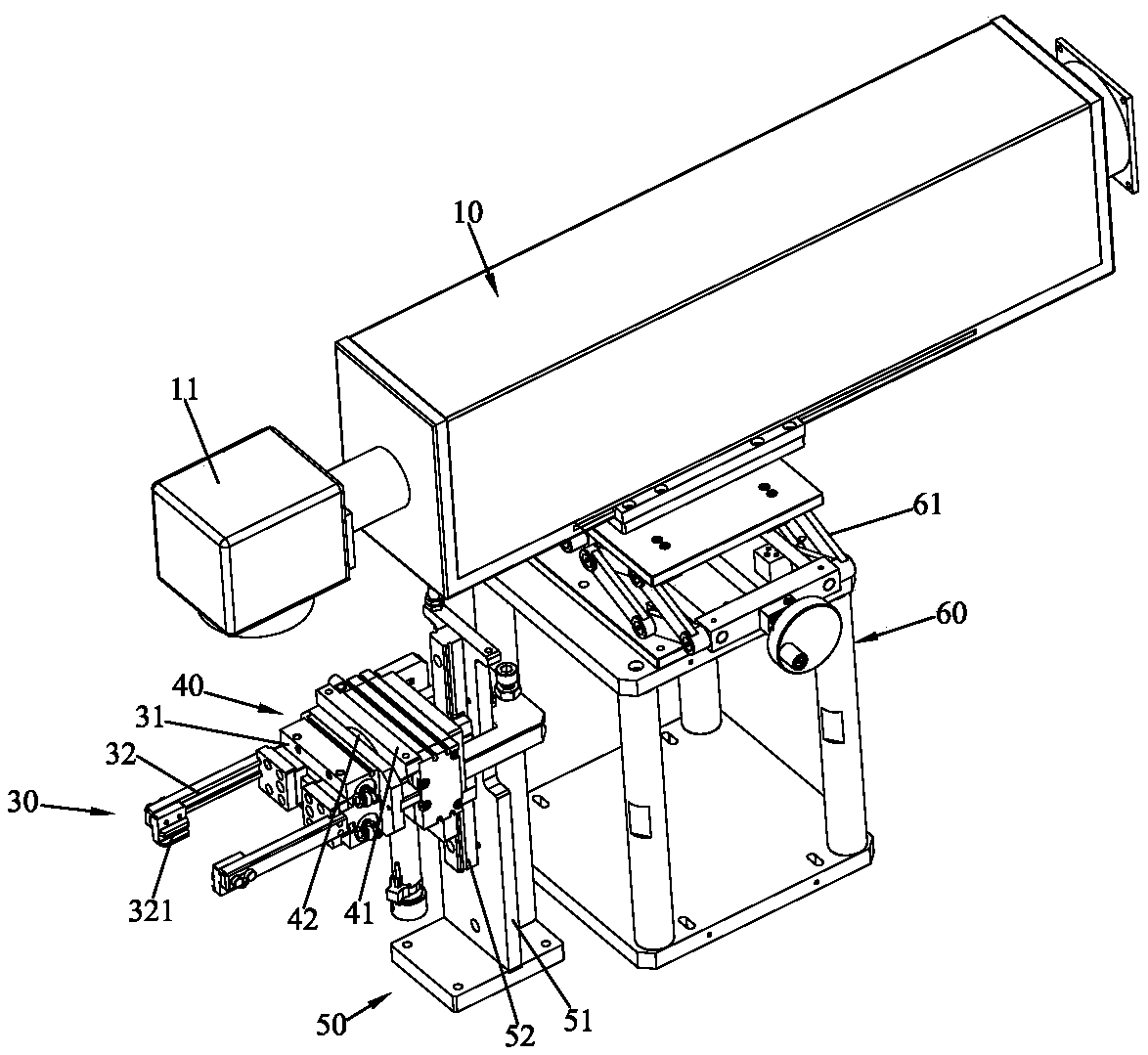

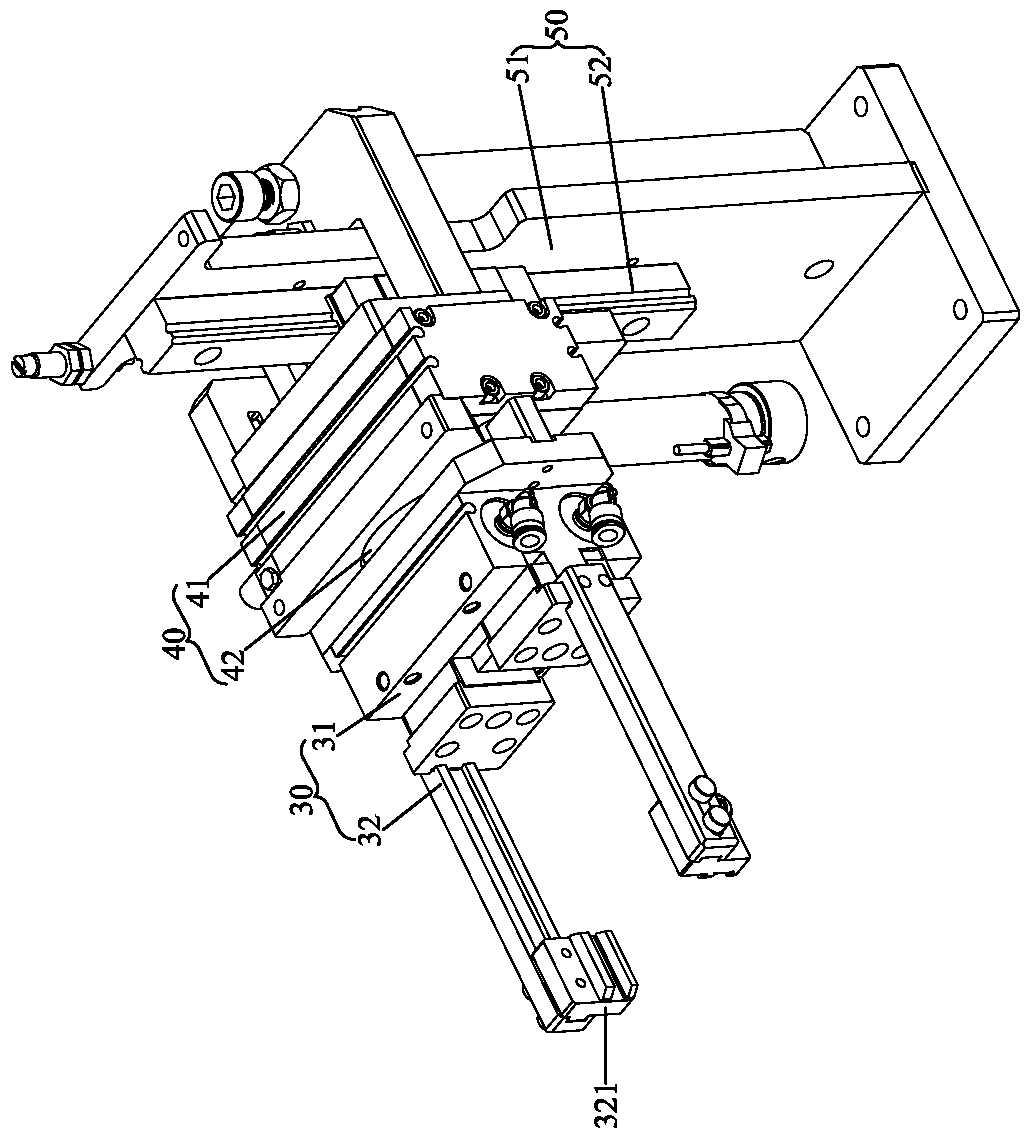

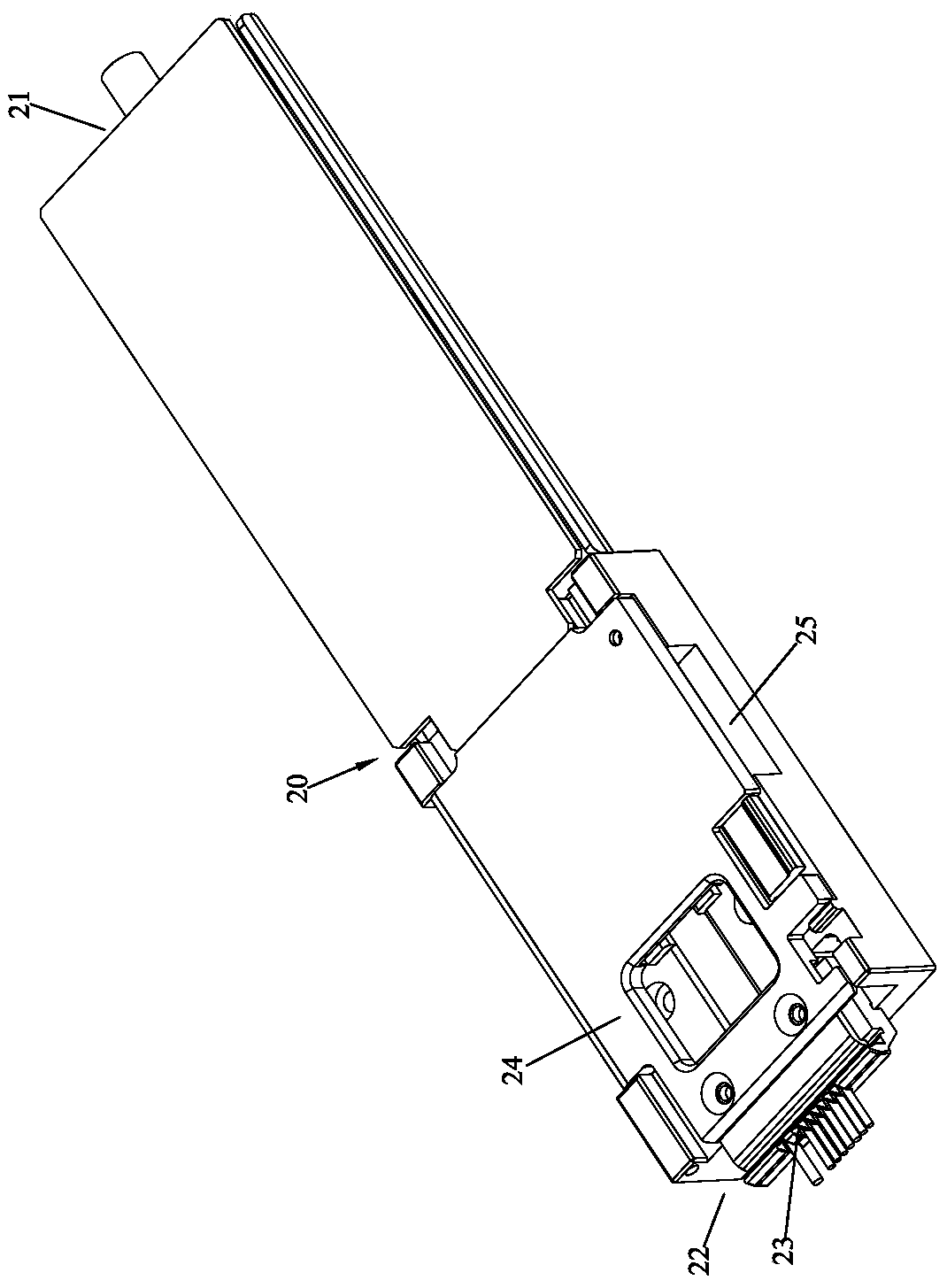

Wire rod laser cutting machine and laser cutting method thereof

PendingCN110465753ASimple structureReduce power consumptionWelding/cutting auxillary devicesAuxillary welding devicesWire rodLaser cutting

The invention discloses a wire rod laser cutting machine and a laser cutting method thereof. The wire rod laser cutting machine comprises a laser cutting device, a wire clamping jig, a clamping mechanism, a turnover mechanism and a displacement mechanism. The clamping mechanism is fixedly arranged on the turnover mechanism. The turnover mechanism is movably arranged on the displacement mechanism.The wire clamping jig is fixed to the clamping mechanism in a selectable manner. The laser cutting device comprises a laser head. The displacement mechanism selectively moves the clamping mechanism toget close to or away from the laser head. By arranging the laser head, turnover of a wire rod can be achieved through the clamping mechanism, the turnover mechanism and the displacement mechanism, and in this way, the laser cutting operation of the front face and the back face of the wire rod can be completed through one laser head, the structure of the laser cutting device is simplified and optimized, the manufacture cost of the device can be reduced, and the size of the whole cutting machine can be smaller. In addition, by omitting a laser function part, the electronic control part of the whole cutting machine can be simpler, and the operation stability and reliability are both substantially improved.

Owner:DONGGUAN SANXIN PRECISION MACHINERY

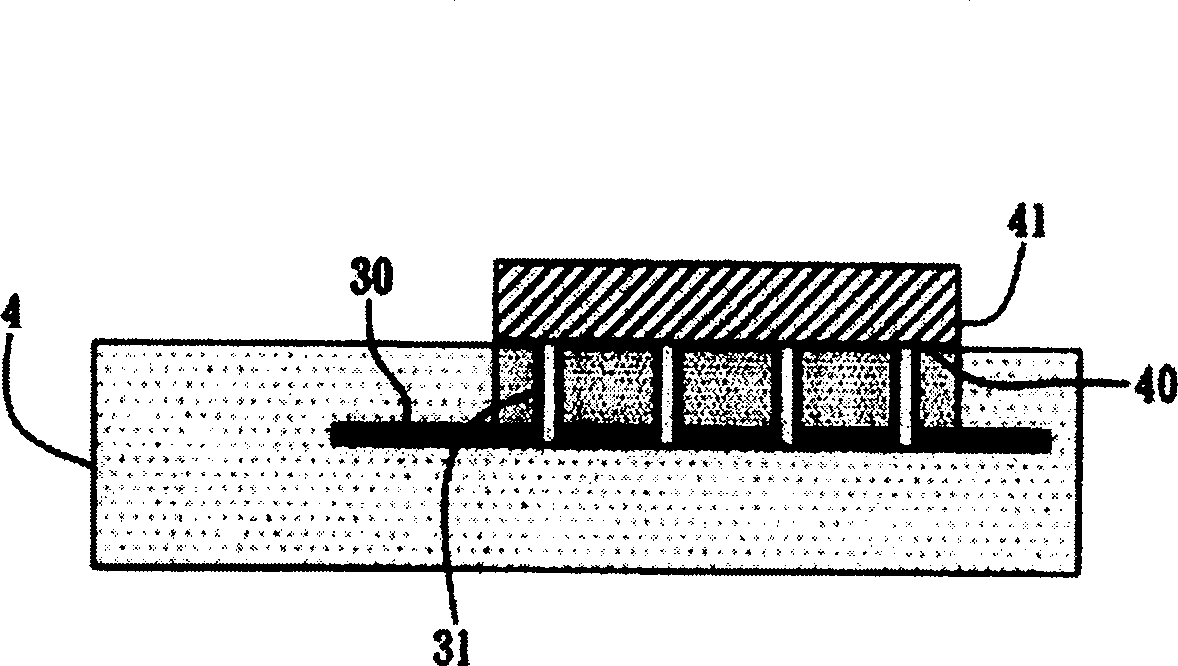

Radiator structure

InactiveCN100466895CIn line with the development trend of miniaturizationEasy to makePrinted circuit detailsDigital data processing detailsElectrical conductorElectrical connection

Owner:INVENTEC CORP

Locking device and optical fiber transceiver module

ActiveCN104101959BIn line with the development trend of miniaturizationSimple structureCoupling light guidesElectromagnetic transceiversTransceiverMiniaturization

The invention discloses a locking device used for locking an optical-fiber joint in an optical device. The optical-fiber joint includes an insert end. The optical device includes a light port. The insert end is inserted into the light port. The locking device includes a support. The support includes a first abutting end and a second abutting end which is arranged to be facing the first abutting end. The optical-fiber joint includes a first fixing part. The optical device includes a second fixing part. The first abutting end and the second abutting end of the support are inserted into the optical-fiber joint and the optical device respectively and abut against the first fixing part of the optical-fiber joint and the second fixing part of the optical device so as to fixedly connect the optical-fiber joint and the optical device. The invention also provides an optical-fiber transceiving module. The locking device and the optical-fiber transceiving module adopt one support to fixedly connect a corresponding optical-fiber joint and a corresponding optical device; and the locking device and the optical-fiber transceiving module are simple in structure, small in occupied space and complying with a miniaturization development trend of optical-fiber transceiving modules.

Owner:HUAWEI TECH CO LTD

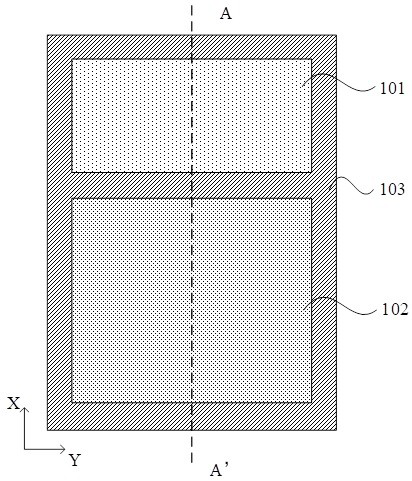

Multi-time programmable memory and preparation method thereof

ActiveCN114464526AIncrease contact areaReduce distanceSolid-state devicesSemiconductor devicesCapacitanceCoupling efficiency

The invention provides a multi-time programmable memory and a preparation method thereof. Part of the gate structure is arranged in the first groove to form the stepped gate structure, so that the contact area of the first well region and the gate structure is increased, the distance of electrons entering the gate structure is shortened, the programming and erasing efficiency of the device is improved, the working voltage is reduced, and the energy consumption of the device is reduced. The gate structure is arranged in the second groove, and part of the gate structure is located in the second groove, so that compared with a planar structure, the contact area of the gate structure arranged in the second groove and the second well region is increased, the coupling efficiency of the capacitor is improved, and the response speed of the device is improved. In addition, due to the arrangement of the first groove and the second groove, the gate structure is of a sunken structure. Under the same device performance, the unit area of the multi-time programmable memory provided by the invention is smaller than the area of a device with the gate structure arranged on a plane.

Owner:晶芯成(北京)科技有限公司 +1

Liquid Immersion High Resolution Small Aperture Fiber Optic Microscope Objective

ActiveCN111624735BReduce Tolerance SensitivityIn line with the development trend of miniaturizationSurgeryEndoscopesImaging qualityMicroscope objective

The invention discloses a liquid-immersion type high-resolution small-diameter optical fiber microscope objective lens, which belongs to the technical field of optical lenses, and comprises a first lens element, a second lens element, a third lens element, The fourth lens element; the first lens element is a spherical positive lens; the second lens element is a spherical doublet lens, including a first lens and a second lens arranged in sequence, the first lens is a negative lens; the second lens is a positive lens; the third lens element is a negative lens; the fourth lens element is a positive lens; and the focal length of each lens element satisfies the following relationship: 0.6

Owner:熊艳辉 +1

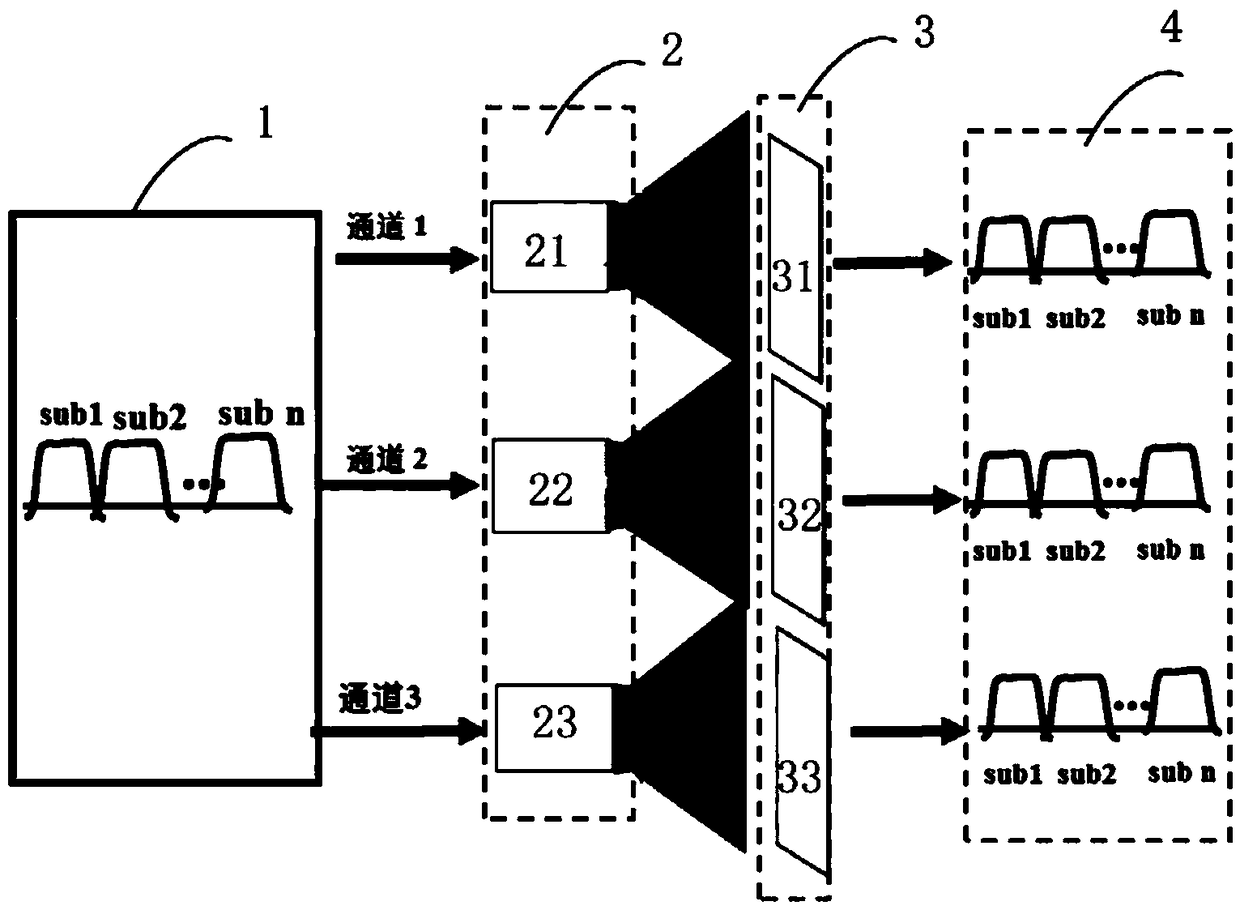

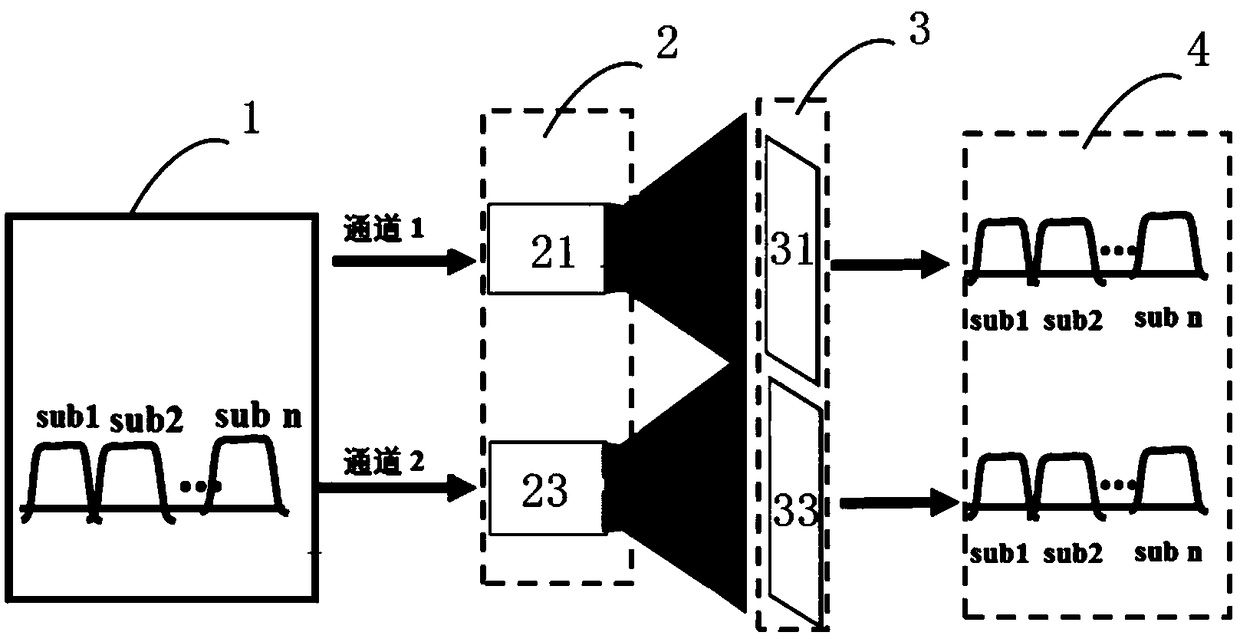

A visible light communication system and its application

ActiveCN105827317BIn line with the development trend of miniaturizationReduce volumeClose-range type systemsElectricityMiniaturization

The invention relates to the field of visible light communication, in particular to a visible light communication system. The visible light communication system comprises a plurality of light signal transmitting assemblies and light signal receiving assemblies in one-to-one correspondence with the light signal transmitting assemblies. The light signal transmitting assemblies are electroluminescent assemblies, and the light signal receiving assemblies are organic photosensitive assemblies. The electroluminescent assemblies can carry different modulating signals with light of different wavelengths. The organic photosensitive assemblies have the advantage of making specific responses to light of a certain waveband and can also accurately receive modulating data transmitted in light channels of different wavebands. Besides, the visible light communication system is small in size and light, meets the development tendency of miniaturization of electrical elements and has a wide application range.

Owner:TSINGHUA UNIV

Fabrication method of microlens array

InactiveCN110673238BContinuous fine adjustmentSmall sizePhotomechanical apparatusLensImage resolutionEngineering

The invention relates to a method for manufacturing a microlens array, and the method comprises the following steps of designing and preparing a super-surface mask; providing a transparent substrate,coating a photoresist on the substrate, and drying and solidifying the film; attaching the super-surface mask to the surface of the photoresist, making the linearly polarized light in the ultravioletband incident on the super-surface mask, and performing exposure on the corresponding photoresist area under the super-surface mask; moving the super-surface mask, and performing exposure on the otherareas of the photoresist until the exposure is completed on the required areas of the photoresist; developing the substrate coated with the photoresist, and forming a microlens array structure on theexposed photoresist after development; subjecting the substrate to ion beam etching by using the microlens array structure on the photoresist as a template, and transferring the microlens array structure on the photoresist to the substrate. The method provided by the invention improves the resolution of exposure by using a super-surface instead of a traditional mask plate, can directly realize continuous and precise adjustment of exposure dose, reduces costs and improves processing accuracy.

Owner:WUHAN UNIV

MEMS (Micro Electro Mechanical System) capacitor-embedded resistor-embedded package loading plate and manufacturing process thereof

PendingCN114466512AImprove alignmentIncrease in sizePrinted circuits structural associationsMultilayer circuit manufactureSolder maskCapacitance

The invention relates to an MEMS (Micro Electro Mechanical System) capacitor-embedded resistor-embedded packaging carrier plate and a manufacturing process thereof, and the process comprises the following steps: preparing three core plates, namely a first core plate, a second core plate and a third core plate; an inner layer circuit of the first core board; pressing the first core plate; etching a second core plate and pressing a film; grooving the film plate; an inner layer circuit of the third core board; pressing a third core plate; laminating a plurality of layers of boards; and uncovering: after drilling and copper plating, outer layer circuit, solder mask and surface treatment are carried out on the semi-finished product board, laser uncovering treatment is carried out on the third core board to form a sound hole, and a finished product packaging carrier board is obtained. The packaging substrate obtained by the invention not only realizes the function of burying the capacitor and the resistor, but also increases the volume of the back cavity under the condition of not increasing the volume of the device, improves the sensitivity and the signal-to-noise ratio of the product, and accords with the development trend of device miniaturization.

Owner:JIANGSU PROVISION ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com