Preparation method of loudspeaker module

A loudspeaker module and loudspeaker technology, applied in the direction of sensors, electrical components, etc., can solve the problem of maximizing the space design of the acoustic cavity, which limits the development trend of the miniaturization of the speaker module, to maximize the space of the cavity, which is beneficial to the performance of the cavity, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

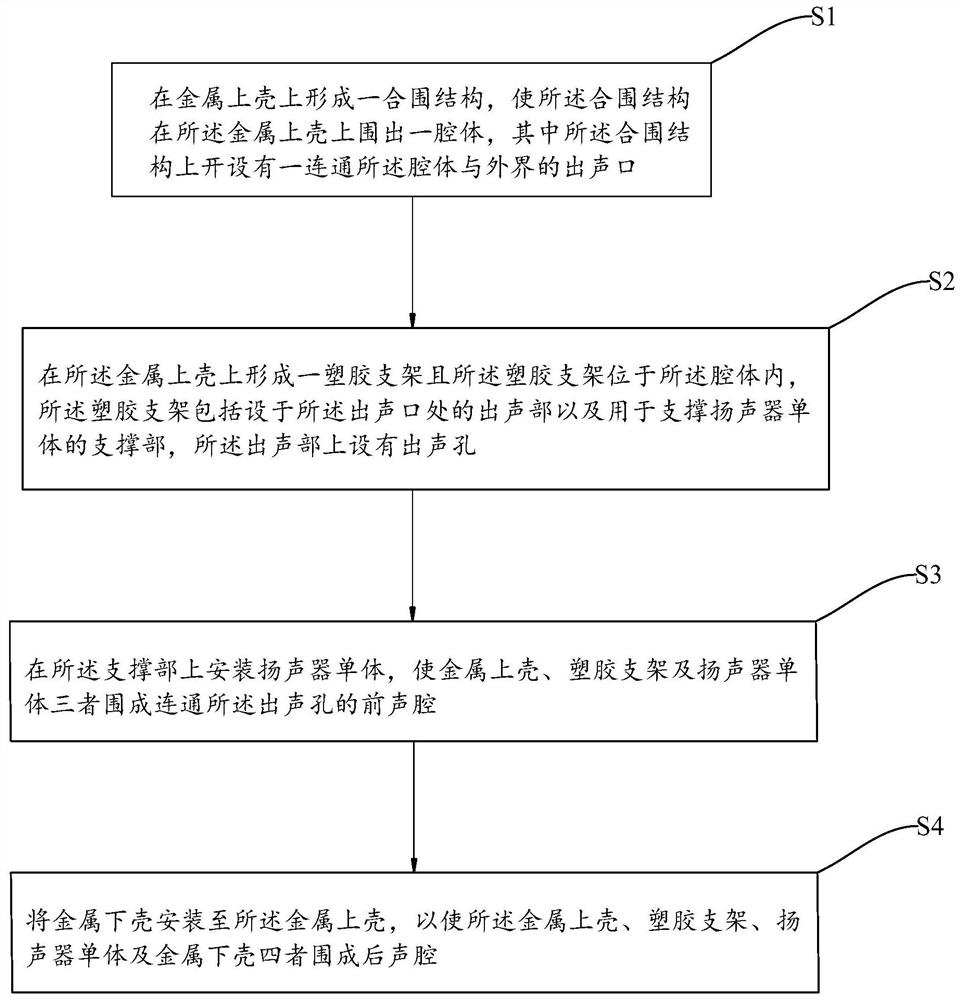

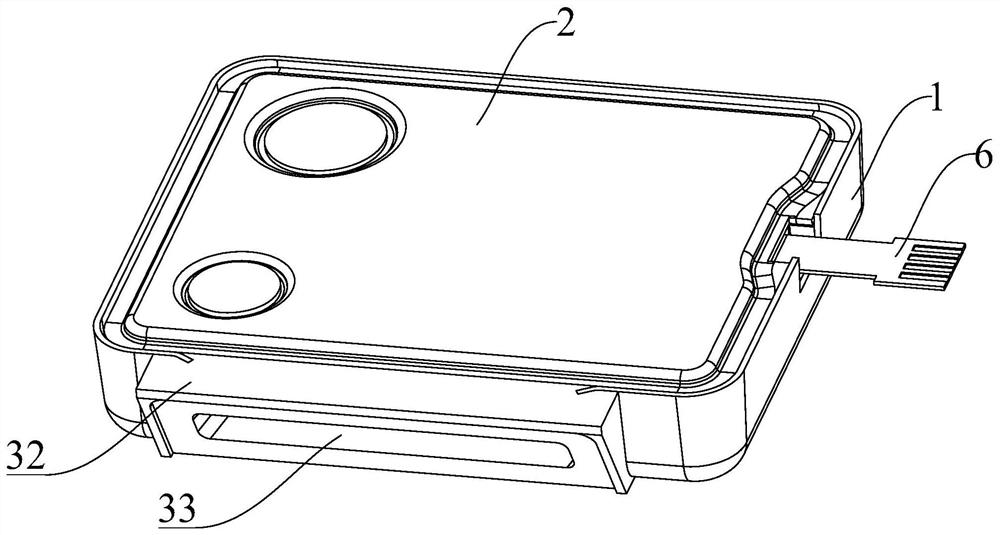

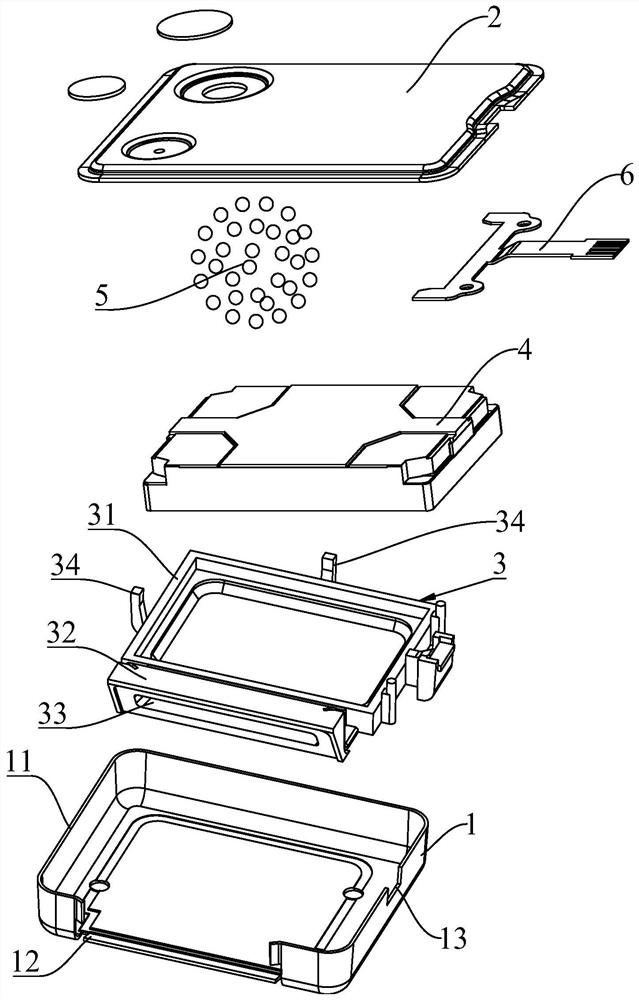

[0020] Please refer to Figure 1 to Figure 4 , a preparation method of a loudspeaker module, comprising the steps of:

[0021] S1. Form an enclosing structure 11 on the metal upper shell 1, so that the enclosing structure 11 encloses a cavity on the metal upper shell 1, wherein the enclosing structure 11 is provided with a cavity that communicates with the outside world The sound outlet 12;

[0022] S2. A plastic bracket 3 is formed on the metal upper shell 1 and the plastic bracket 3 is located in the cavity. The plastic bracket 3 includes a sound outlet 32 arranged at the sound outlet 12 and for The support part 31 supporting the speaker unit 4, the sound outlet part 32 is provided with a sound outlet 33;

[0023] S3. Install the speaker unit 4 on the support portion 31, so that the metal upper shell 1, the plastic bracket 3 and the speaker unit 4 form a front acoustic cavity 7 connected to the sound outlet 33;

[0024] S4. Install the metal lower case 2 to the metal up...

Embodiment 1

[0043] Please refer to Figure 1 to Figure 4 , Embodiment 1 of the present invention is: a preparation method of a loudspeaker module, comprising the following steps:

[0044] S1. Form an enclosing structure 11 on the metal upper shell 1, so that the enclosing structure 11 encloses a cavity on the metal upper shell 1, wherein the enclosing structure 11 is provided with a cavity that communicates with the outside world The sound outlet 12;

[0045] Specifically, step S1 includes the following steps:

[0046] S11. Stamping the periphery of a piece of metal sheet, so that the periphery of the metal sheet is folded in the same direction to form the enclosing structure 11;

[0047] S12. Punching out the sound opening 12 on the metal sheet;

[0048] S13. Punching the avoidance groove 13 on the metal sheet;

[0049] Optionally, the step S1 may be carried out sequentially according to the processing sequence of S11, S12 and S13, or may be carried out sequentially according to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com