Dielectric waveguide filter

A dielectric waveguide and filter technology, applied in the field of dielectric waveguide filters, can solve problems such as insufficient filter strength, and achieve the effects of light weight, high suppression, and effective support structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

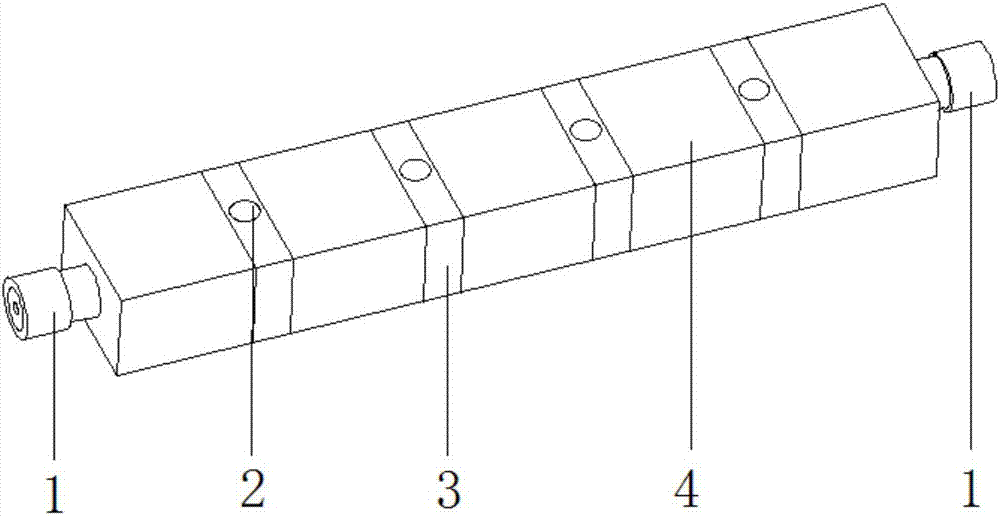

[0037] Such as figure 1 As shown, a dielectric waveguide filter includes a filter body; a radio frequency connector is arranged on the filter body. In this embodiment, the radio frequency connector includes an input radio frequency connector and an output radio frequency connector; the input radio frequency connector and the output radio frequency connector are respectively located at two ends of the filter body.

[0038] The filter body includes a filter dielectric block; the filter dielectric block includes several dielectric single cavities and several coupling windows, and adjacent dielectric single cavities are connected through the coupling windows. Several dielectric single cavities are sequentially connected end to end through coupling windows.

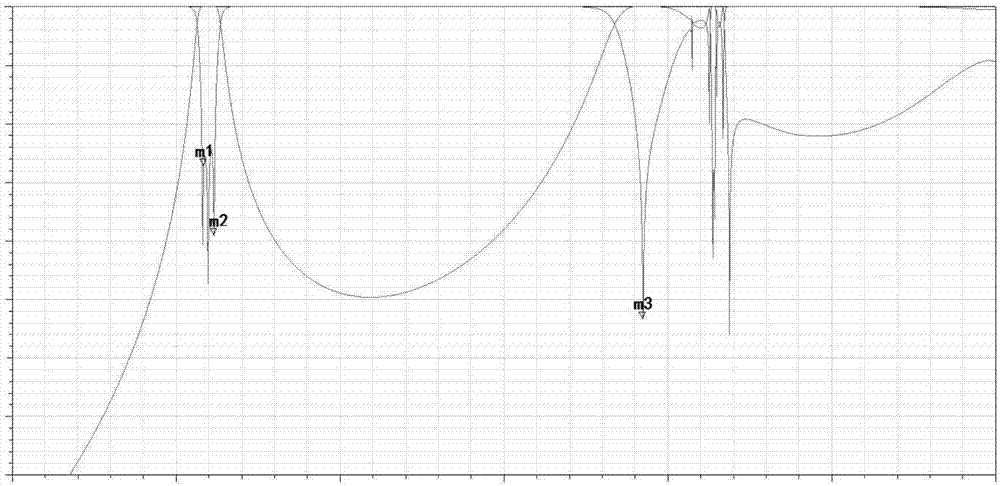

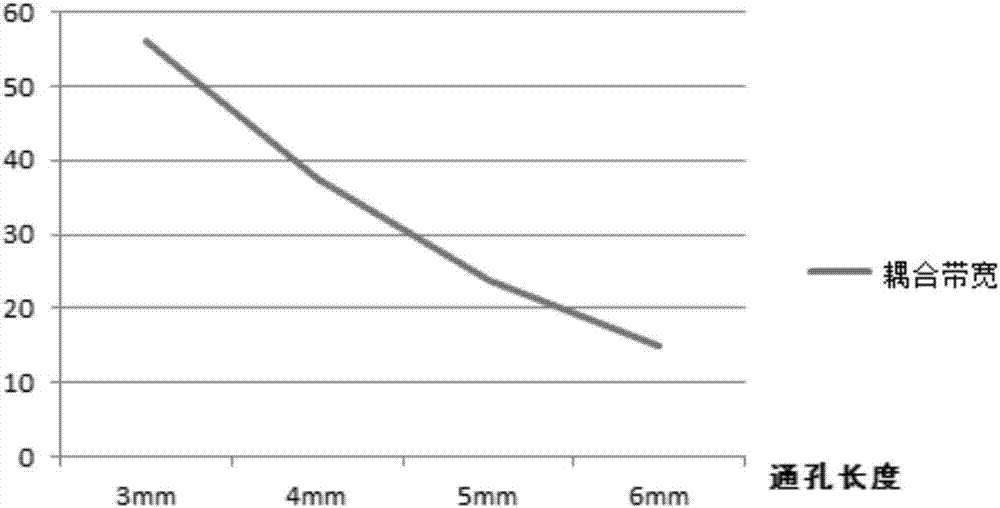

[0039] A through hole is arranged in the middle of the coupling window, and the through hole can be of any shape. In this embodiment, the through hole is a fully rounded rectangular hole with a length L and a width K, and th...

Embodiment 2

[0046] Such as Figure 4 As shown, a dielectric waveguide filter includes a filter body; a radio frequency connector is arranged on the filter body. In this embodiment, the radio frequency connector includes an input radio frequency connector and an output radio frequency connector; the input radio frequency connector and the output radio frequency connector are respectively located at two ends of the filter body.

[0047] The filter body includes a filter dielectric block; the filter dielectric block includes several dielectric single cavities and several coupling windows, and adjacent dielectric single cavities are connected through the coupling windows. Several dielectric single cavities are sequentially connected end to end through the coupling window; the dielectric single cavity can be in any shape, and similarly, the filter body can also be in any shape.

[0048] A through hole is arranged in the middle of the coupling window, and the through hole can be of any shape. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com