Glass blind hole machining method

A processing method and glass technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of low cost and low process temperature, and achieve the effects of high adhesion, high deposition quality, and low leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Glass-based blind vias were fabricated using the following steps:

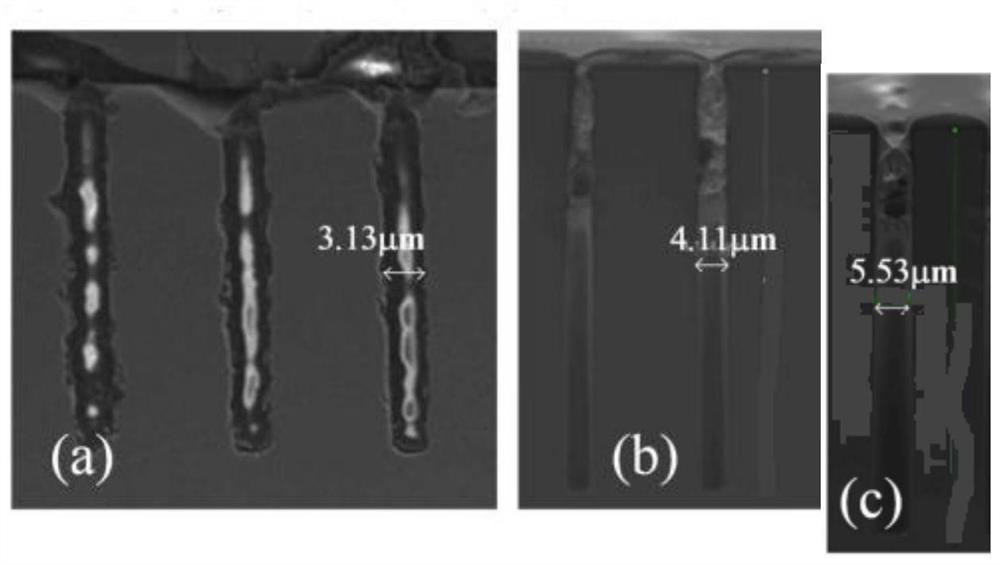

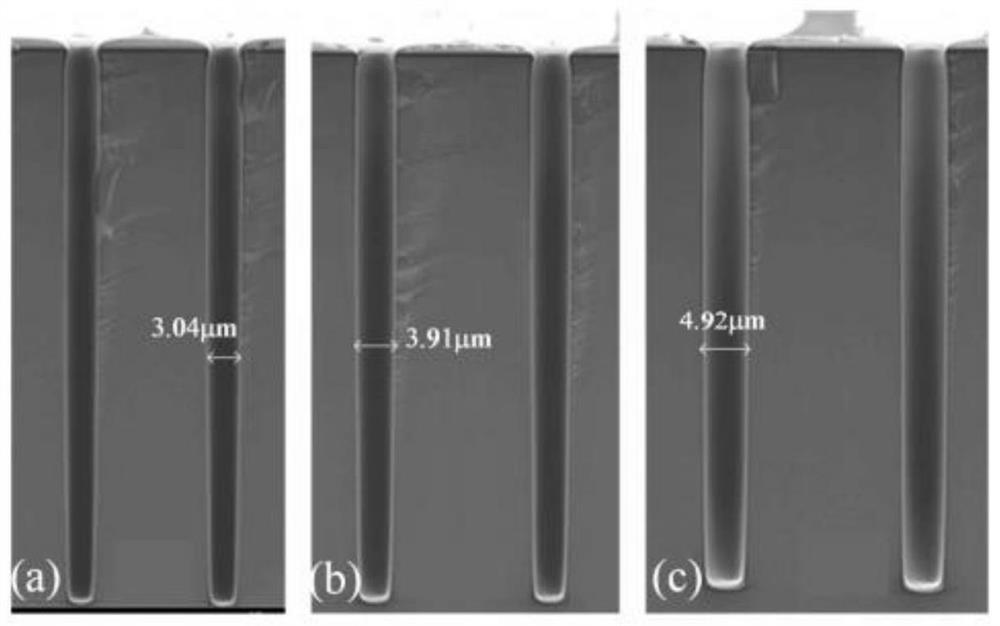

[0102] a. Etch blind holes with a diameter of 3 μm and a depth of 45 μm on the front of the glass, and the number of blind holes is 25*25;

[0103] b. Adhesion layer deposited on the side wall of the deep hole:

[0104] b1, the PI-5J polyimide solution that the viscosity is 1200cP is drip-coated on the glass surface, guarantees that the high polymer solution covers the glass surface;

[0105] b2. Transfer the glass to an environment with an air pressure of 100Pa, and let it stand for 10 minutes to make the polymer solution fill the deep hole;

[0106] b3. Fix the glass on the turntable, the center of the glass deviates from the center of rotation of the turntable, drive the turntable to rotate, the glass center line speed is 2000rpm, the rotation time is 30s, and the polymer solution on the glass surface and in the deep hole is thrown off;

[0107] b4. Drying to solidify the polymer solution remaining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com