Fabrication method of microlens array

A technology of a microlens array and a manufacturing method, which is applied to the photoengraving process and instruments of lenses and pattern surfaces, can solve the problems of increased manufacturing cost, increased manufacturing difficulty, low processing accuracy, etc., and achieves low manufacturing cost and lens size. Small size and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] For a better understanding of the present invention, the following examples are further descriptions of the present invention, but the content of the present invention is not limited to the following examples.

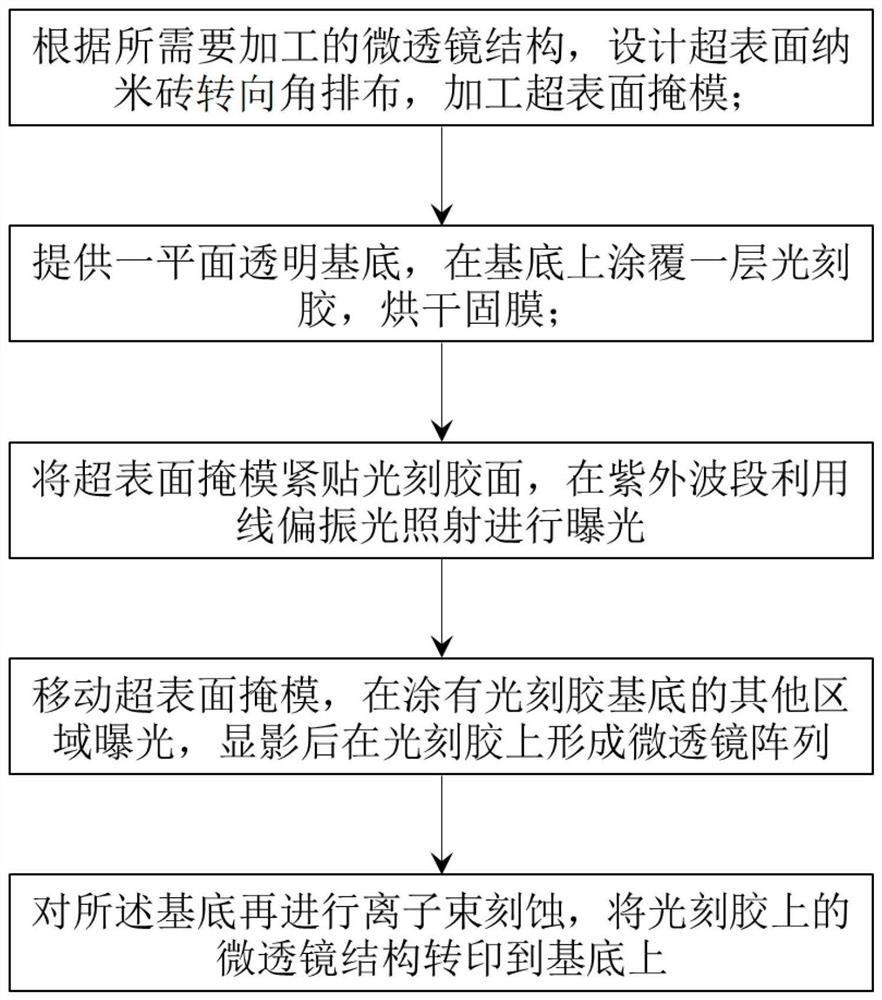

[0029] In view of the problems of limited grayscale, high production cost, and limited grayscale control level in the production of microlens arrays by the grayscale mask method in the prior art, the present invention provides a method for producing a microlens array. The production process is as follows: figure 1 shown, including the following steps:

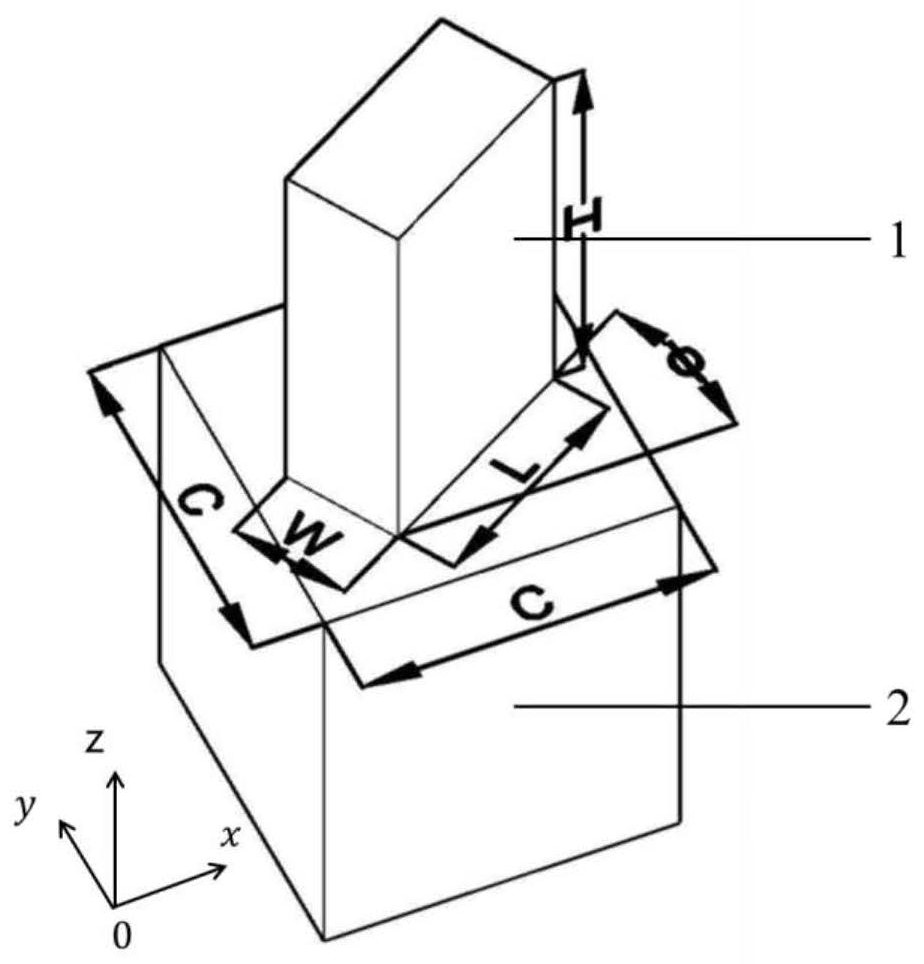

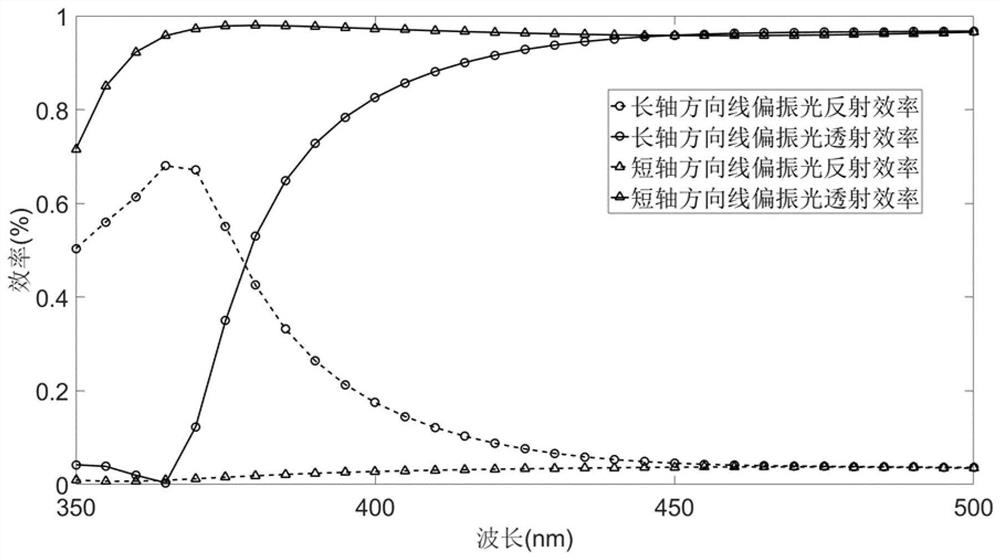

[0030] First, design and make a metasurface mask; the metasurface mask includes a nanobrick array, and the nanobrick array includes a plurality of nanobrick structural units, each nanobrick structural unit includes a working surface and nanobricks arranged on the working surface, The x-axis and y-axis are respectively set as the two sides parallel to the working surface to establish the xoy coordinate system. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com