Eccentric wheel with adjustable eccentric distance

A technology of eccentric wheel and eccentric distance, applied in the field of eccentric wheel, can solve problems such as troublesome, unable to achieve continuous and precise adjustment, and achieve the effect of continuous and precise adjustment, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described;

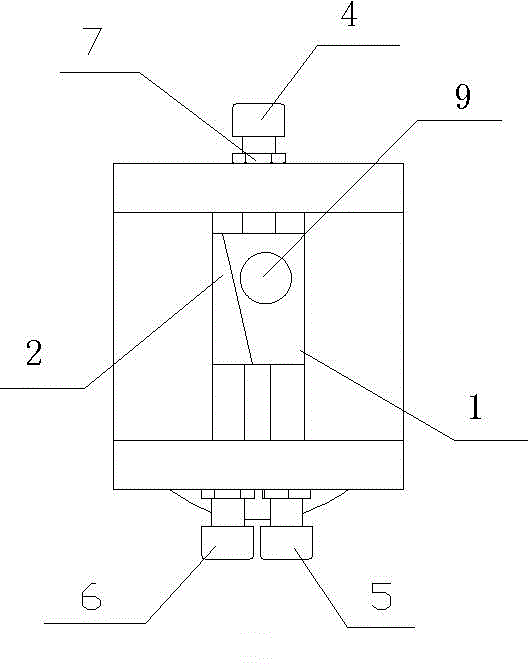

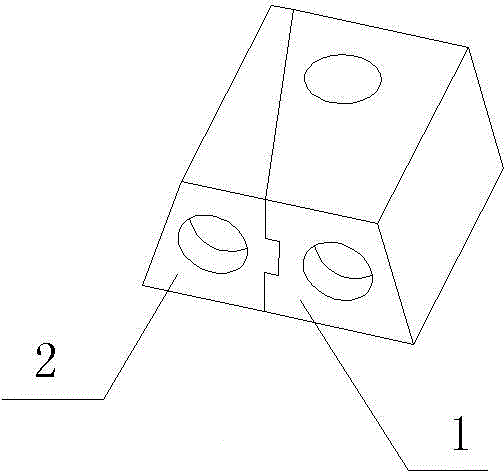

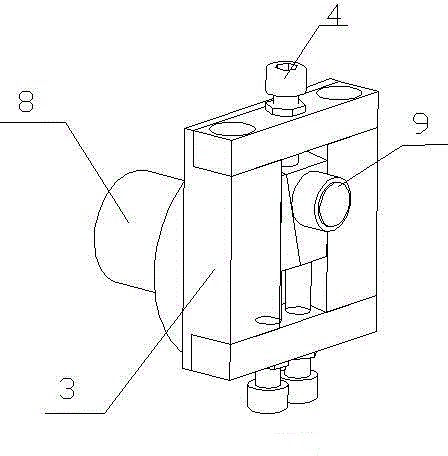

[0014] An eccentric wheel with adjustable eccentricity, which is applied to the dovetail groove in the main design, and uses the inclined surfaces of the eccentric block A1 and the eccentric block B2 to realize the tension of the eccentric block in the dovetail groove, so as to achieve the function of anti-slip locking and positioning. It includes eccentric block A1, eccentric block B2, base 3, central shaft 8, and eccentric shaft 9, and is characterized in that: eccentric block A1 and eccentric block B2 cooperate to form a trapezoidal eccentric body (such as figure 2 ), the eccentric body is arranged in the dovetail groove of the base 3, and the eccentric shaft 9 runs through the eccentric block A1.

[0015] Further, the eccentric block A1 is provided with a groove, and the eccentric block B2 is provided with a protrusion matched therewith.

[0016] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com