Wire rod laser cutting machine and laser cutting method thereof

A cutting machine and laser technology, applied in welding/cutting auxiliary equipment, auxiliary devices, laser welding equipment, etc., can solve the development trend of high input cost, increase manufacturing cost, large space for placement, etc., to meet the rhythm of the process flow Demand, reduce power consumption, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

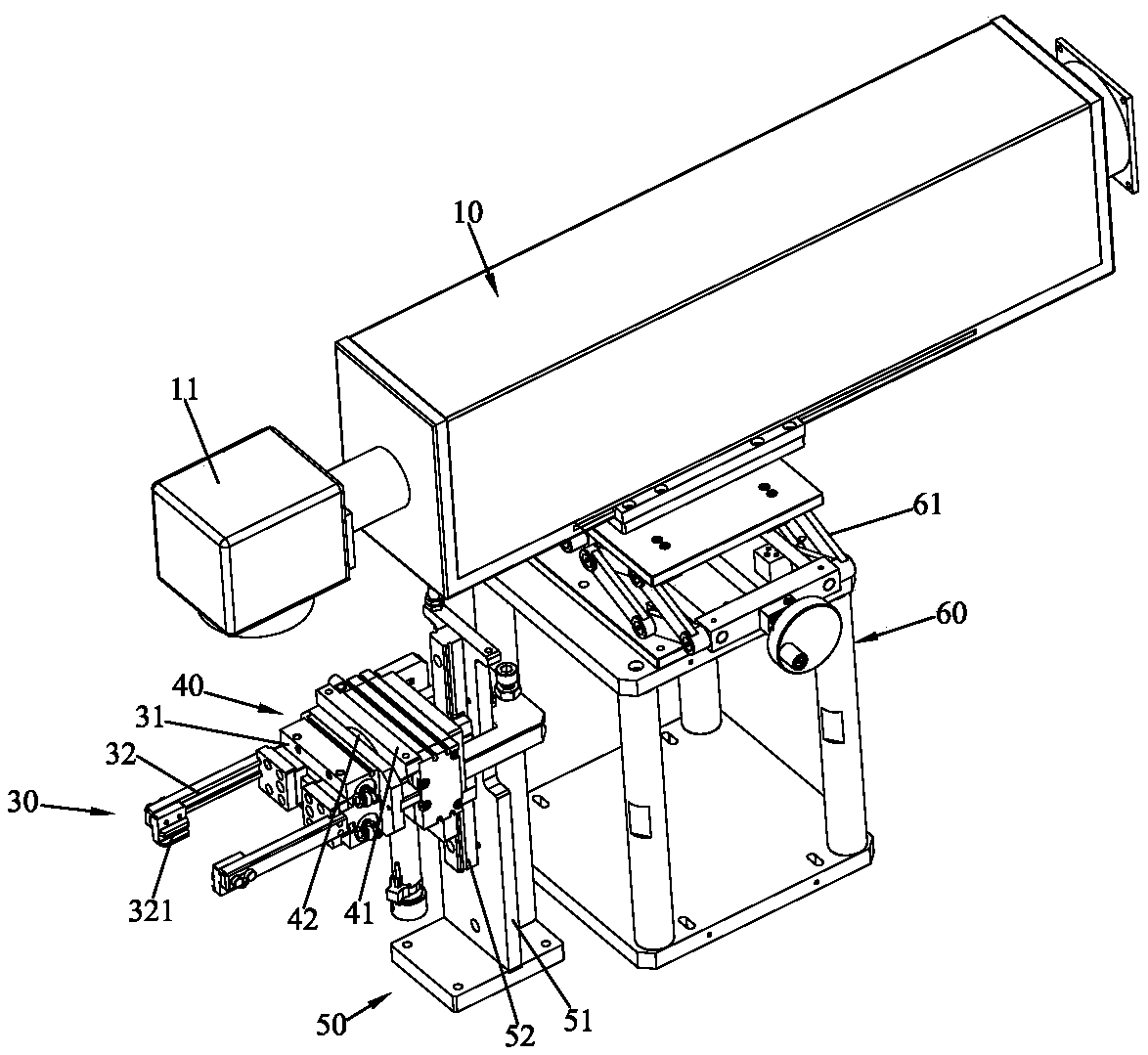

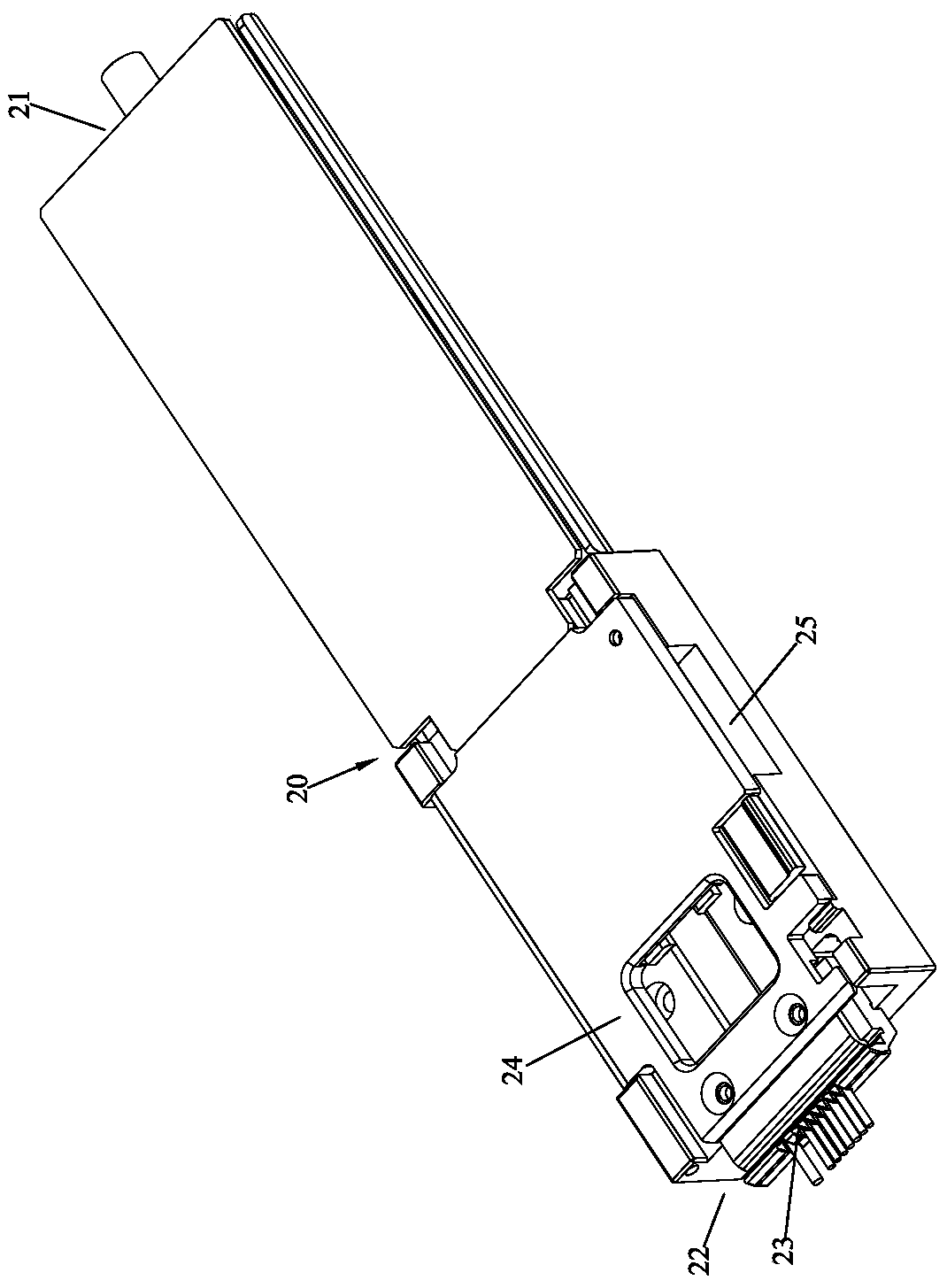

[0048] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, which is a wire laser cutting machine and its laser cutting method, including a laser cutting device 10 for laser cutting wire and a clamp for clamping the wire Wire fixture 20.

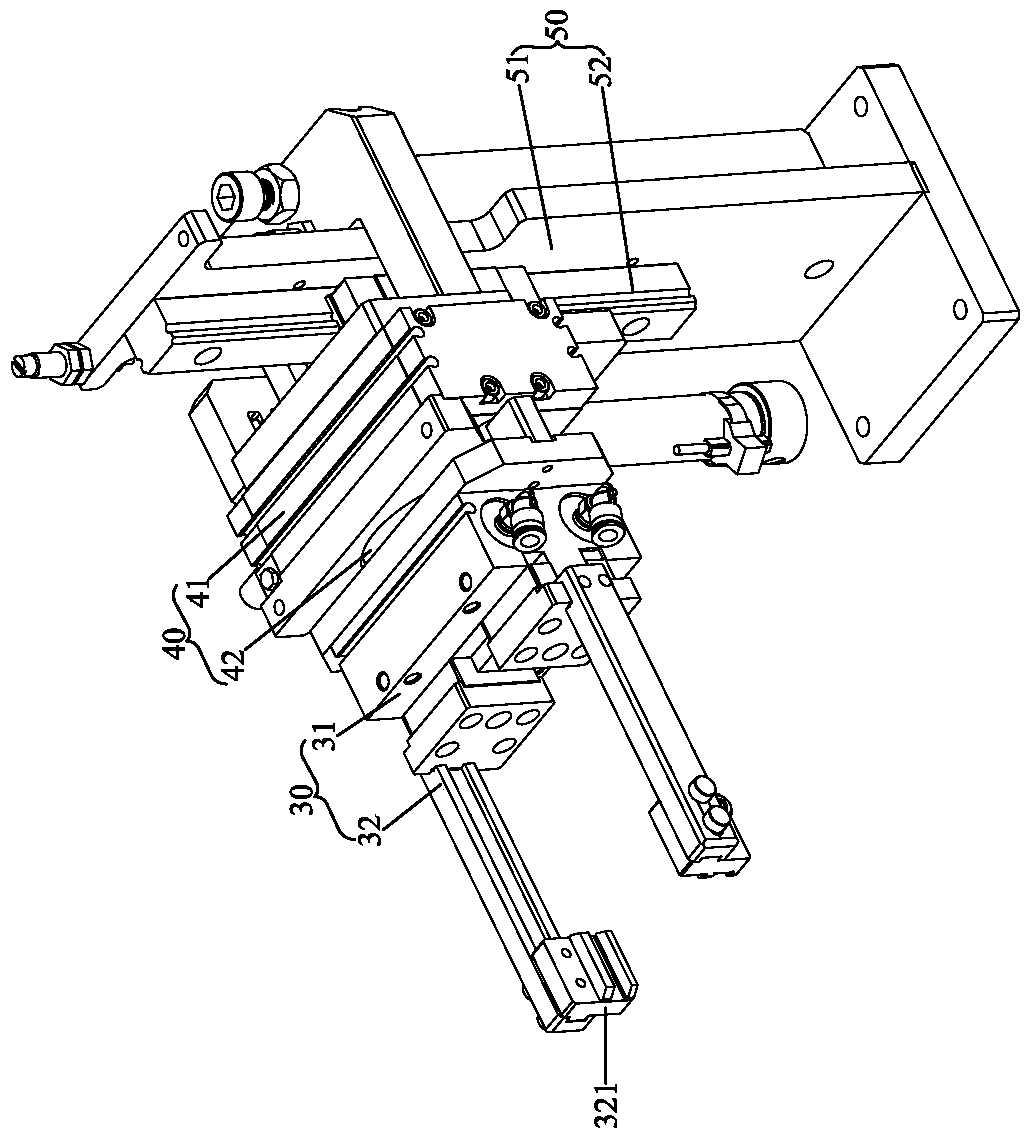

[0049] The wire laser cutting machine also includes a clamping mechanism 30, a turning mechanism 40 and a displacement mechanism 50, the clamping mechanism 30 is fixed on the turning mechanism 40, and the turning mechanism 40 is movably arranged on the displacement mechanism 50, The clamping fixture 20 can be selectively fixed on the clamping mechanism 30; the laser cutting device 10 has a laser head 11, and the displacement mechanism 50 can selectively move the clamping mechanism 30 to approach or move away from the laser head 11 .

[0050] In this embodiment, the displacement mechanism 50 includes a fixed plate 51 and a vertical displacement guide bar 52 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com