MEMS (Micro Electro Mechanical System) capacitor-embedded resistor-embedded package loading plate and manufacturing process thereof

A technology of encapsulating carrier boards and manufacturing processes, which is applied in the directions of multilayer circuit manufacturing, printed circuit manufacturing, and printed circuits connected with non-printed electrical components. Poor effect and other problems, to achieve the effect of increasing volume, improving sensitivity and signal-to-noise ratio, and improving alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

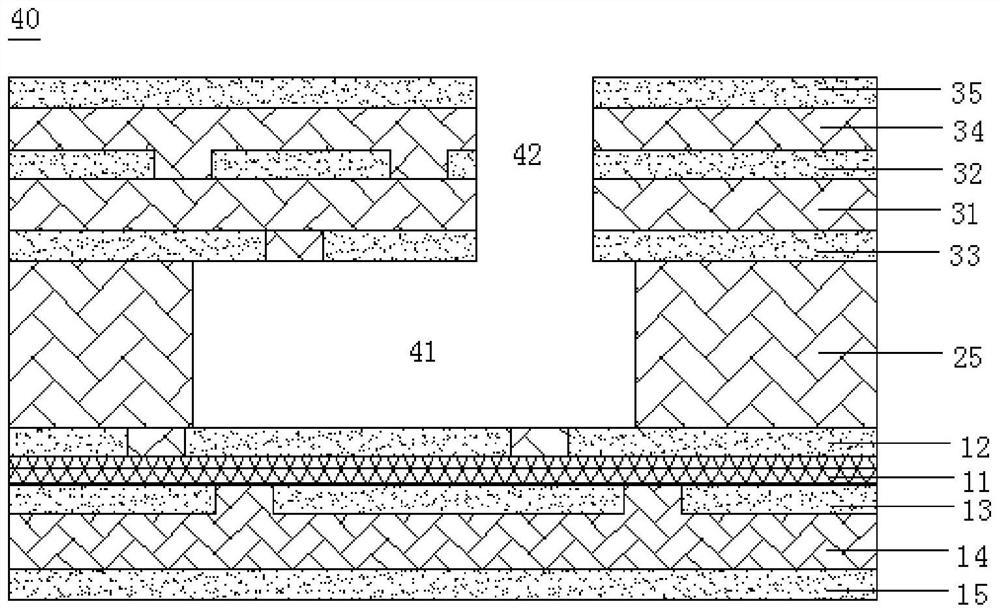

[0057] Example: as Figure 1-11 As shown, a manufacturing process of a MEMS buried capacitance and buried resistance package carrier board includes the following steps:

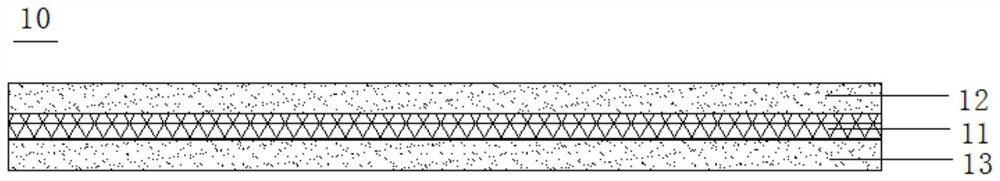

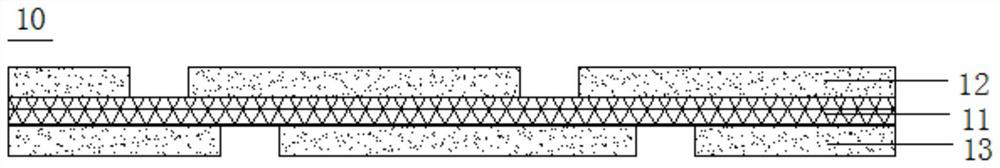

[0058] Step 1: Prepare three core boards, namely the first core board 10 , the second core board 20 and the third core board 30 , wherein, such as figure 2 As shown, the first core board 10 includes a capacitor layer 11 and a first copper foil layer 12 and a second copper foil layer 13 respectively disposed on the front and back sides of the capacitor layer, such as Figure 5 As shown, the second core board 20 includes a second insulating layer 21 and a fourth copper foil layer 22 and a fifth copper foil layer 23 respectively disposed on the front and back sides of the second insulating layer, such as Figure 8 As shown, the third core board 30 includes a third insulating layer 31 and a sixth copper foil layer 32 and a seventh copper foil layer 33 respectively disposed on the front and back sides of the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com