Double-support elastic sheet type anti-shake system, lens driving device and camera shooting equipment

A lens-driven, double-bracket technology, applied in projection devices, printing devices, focusing devices, etc., can solve problems that affect assembly efficiency and product quality, unfavorable miniaturization development, and large volume of anti-shake motors, etc., to achieve mass production Production, reduce the difficulty of manufacturing and assembly processing, and improve the reliability of power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

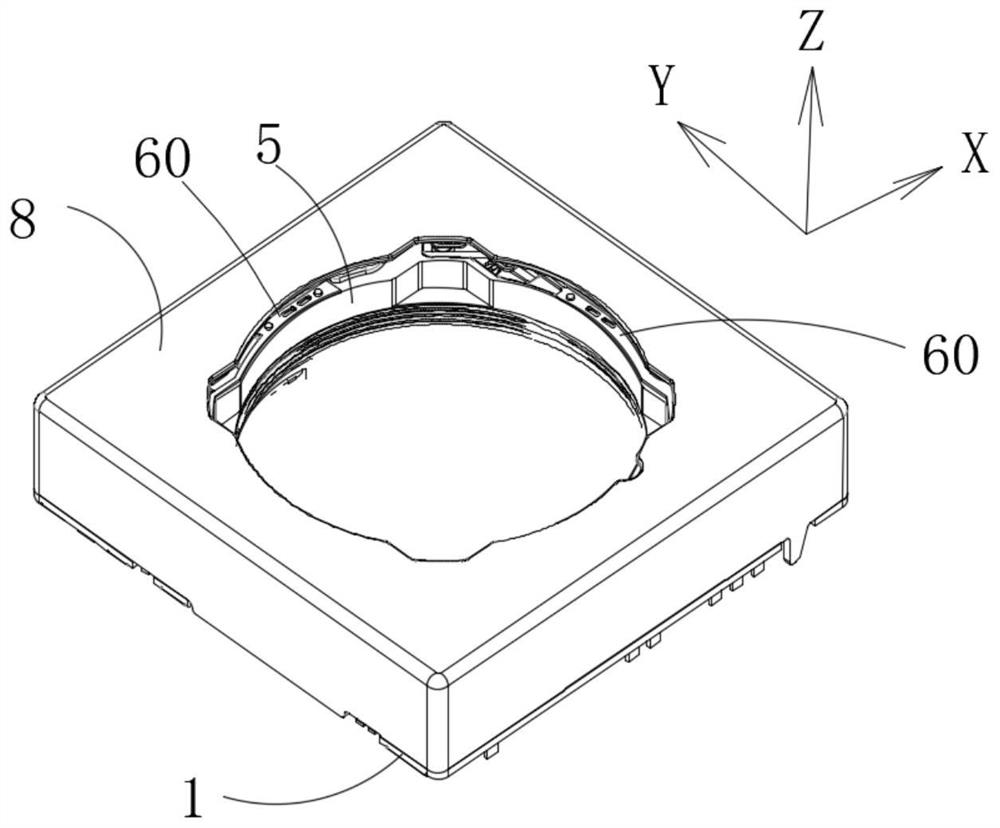

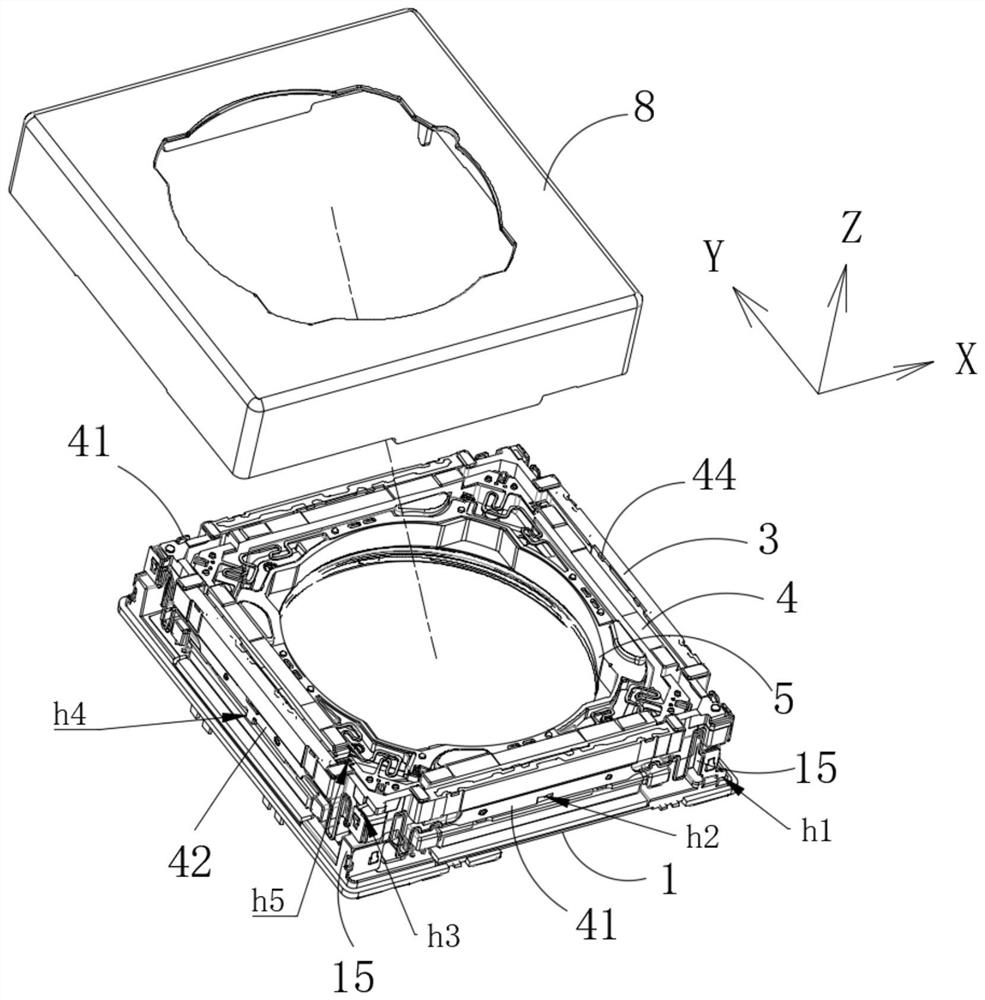

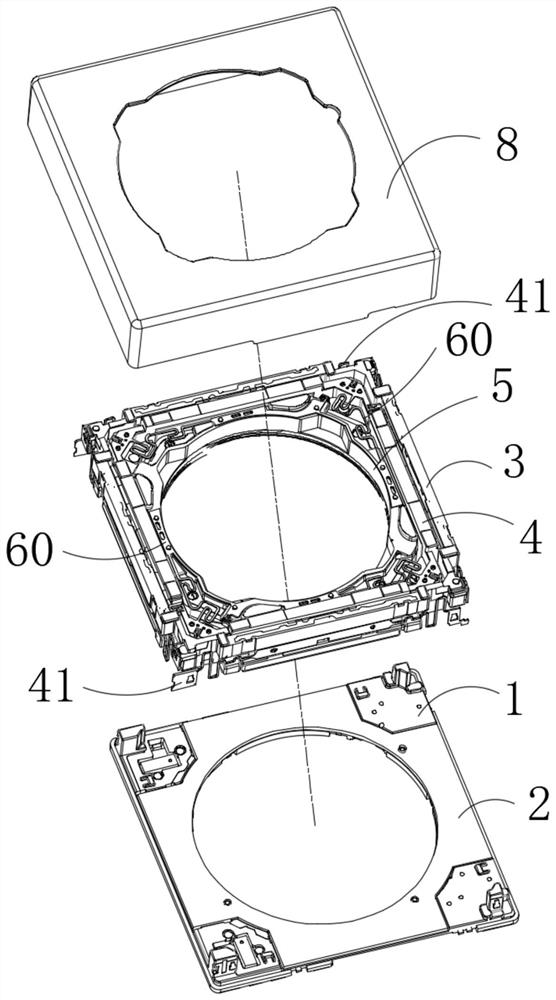

[0093] Such as Figure 1-Figure 4 As shown, this embodiment provides a lens drive device, including the lens drive base 1 described in Embodiment 1, the anti-shake outer frame 3 that moves relative to the lens drive base 1 on the Y axis, and the anti-shake outer frame 3 that moves on the X axis relative to the anti-shake outer frame 3. An inner anti-shake frame 4 that moves around the shaft, and the inner anti-shake frame 4 is located in the outer anti-shake frame 3 .

[0094] Such as Figure 2-Figure 4 As shown, the lens driving device also includes a lens carrying frame 5 located in the anti-shake inner frame 4, and the lens carrying frame 5 is connected to the anti-shake inner frame 4 through an upper reed 6 and a lower reed 7, as Figure 7-Figure 10As shown, the upper reed 6 of this embodiment includes two bullet pieces 60, and the two embedded metal blocks 47 electrically connected to the second reed 42 are respectively electrically connected to the two bullet pieces 60,...

Embodiment 3

[0101] Based on Example 2, such as Figure 11-Figure 12 As shown, this embodiment provides an imaging device, the imaging device has the lens driving device described in Embodiment 2, and the lens driving device carries a lens. Camera devices such as mobile phones and electronic tablets, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com