Heat-curable resin composition

A resin composition and thermosetting technology, which is applied in the field of thermosetting resin compositions, can solve problems such as cracking of cured products, and achieve the effect of excellent operability without compromising reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

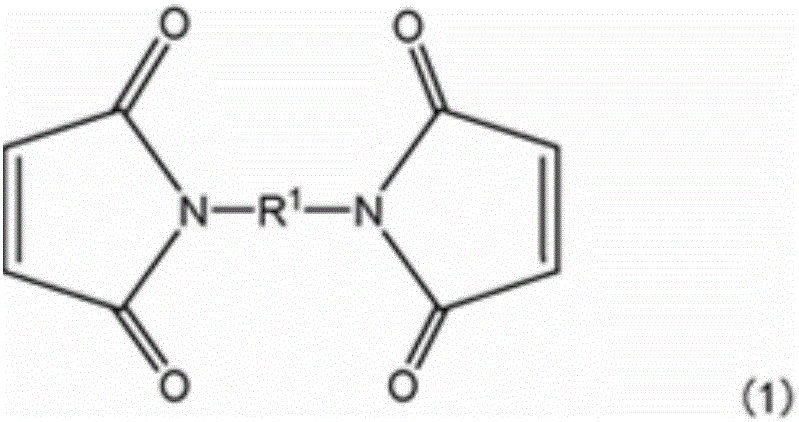

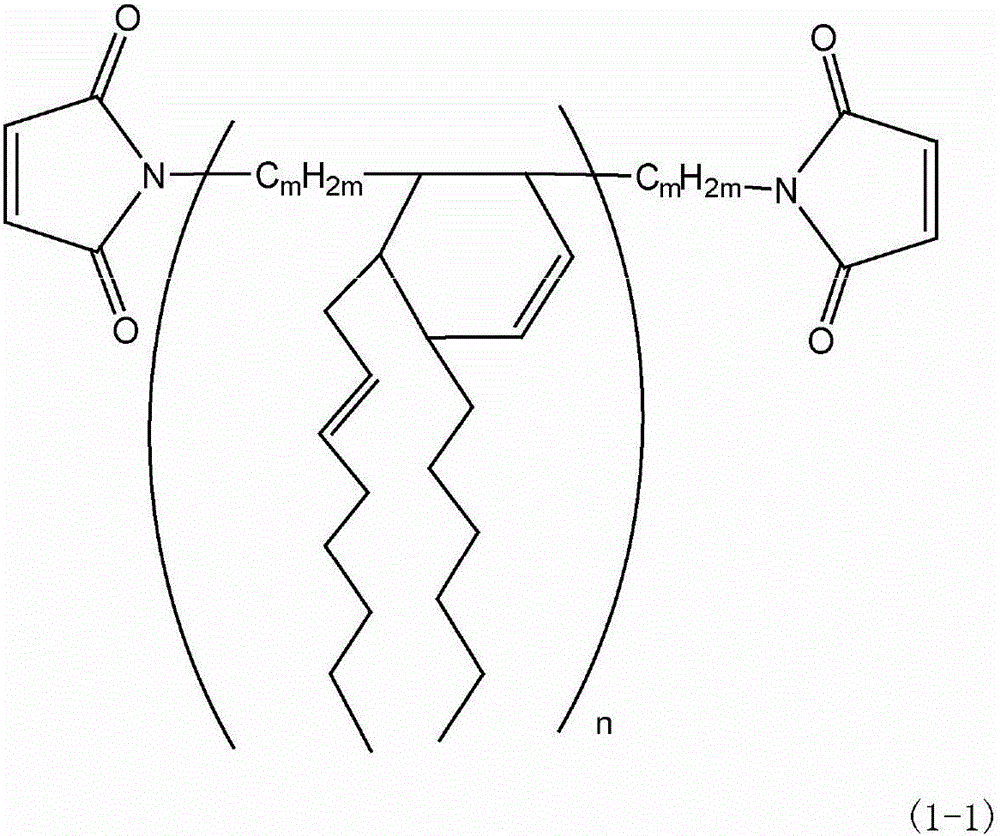

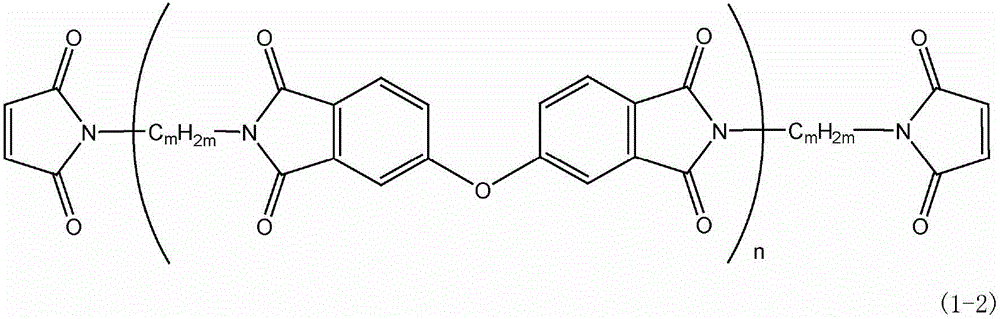

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0090] The preparation method of thermosetting resin composition

[0091] The thermosetting resin composition of the present invention can be prepared, for example, by the method described below.

[0092] For example, (A) thermosetting resin and (B) liquid bismaleimide compound are mixed and stirred simultaneously or separately as needed while heat-treating, and then dissolved and / or dispersed to obtain (A) and (B) a mixture of components. At least one of an inorganic filler, a mold release agent, a flame retardant, and other additives of the (C) component of the ion trap may be added and mixed in the mixture of (A) and (B) components. Each component of (A)-(C) may be used individually by 1 type, and may use 2 or more types together.

[0093] The preparation method of the composition and the equipment for mixing, stirring and dispersing are not particularly limited. Specifically, for example, a crush mill, a two-roll mill, a three-roll mill, a ball mill, a planetary mixer o...

Embodiment

[0096] Hereinafter, although an Example and a comparative example are shown and this invention is demonstrated concretely, this invention is not limited to a following example.

[0097] About Examples 1-26 and Comparative Examples 1-15, each component shown below was mixed with the composition shown in Tables 1-3, and the thermosetting resin composition was prepared. This thermosetting resin composition was further molded under the conditions of 100° C.×2 hours and 150×4 hours to obtain respective cured products. In addition, in Tables 1-3, the quantity of (A)-(C) component is shown by mass parts.

[0098] (A) Thermosetting resin

[0099] (A1) Thermosetting resin components (epoxy resin and cyanate resin)

[0100] (A1-1) Bisphenol A epoxy resin (YD-8125: manufactured by Mitsubishi Chemical Corporation)

[0101] (A1-2) Aminophenol type trifunctional epoxy resin (jER 630: manufactured by Mitsubishi Chemical Corporation)

[0102] (A1-3) Bis-E type cyanate resin (LECy: manufac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com