Puller roller in textured-yarn spinning technology based on real-time lubricating treatment

A technology of space-changing yarn and spinning, which is applied in the field of textile processing, and can solve problems such as the impact on the quality of formed products and the wear and tear of drawing and stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

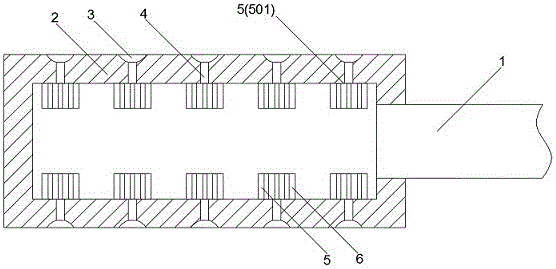

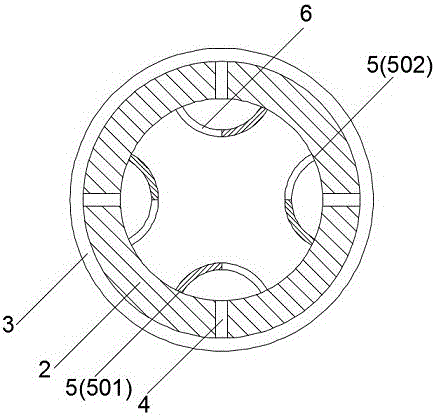

[0015] Such as figure 1 and figure 2 The drawing roller in the shown a kind of air variable yarn spinning process based on real-time lubrication treatment includes a driving shaft body 1, and a roller main body 2 is arranged on the driving shaft body 1, and the roller main body 2 adopts a hollow structure; On the side end surface of the roller main body 2, a plurality of traction grooves 3 extending radially on the roller main body 2 are arranged, and a plurality of traction grooves 3 are evenly distributed in the axial direction of the roller main body 2; Each is provided with a plurality of lubricating oil passages 4 connected to the interior of the roller main body 2. In the roller main body 2, each lubricating oil passage 4 is provided with a lubricating end plate 5 at a corresponding position on the inner wall of the roller main body 2, and the lubricating end plate 5 is sampled. The arc-shaped structure, the end of each lubricating oil passage 4 on the inner wall of th...

Embodiment 2

[0019] As an improvement of the present invention, such as figure 2 As shown, the lubricating end plate 5 includes a first end portion 501 and a second end portion 502 distributed sequentially above its extension direction, and the first end portion 501 and the second end portion 502 are both fixed to the bottom of the roller main body 2 On the inner wall, the lubricating end plate 2 extends in an arc between the first end portion 501 and the second end portion 502; 4, and the first end 501 of the lubricating end plate 5 is distributed sequentially in the direction of rotation of the roller main body 2; among the lubricating end plates, an oil inlet hole 6 is provided at the corresponding position of the second end 502 . By adopting the above technical solution, the structure of the lubricating end plate can be set so that the lubricating end plate forms a closed structure relative to the lubricating oil passage, so that the lubricating oil passage inside the lubricating end ...

Embodiment 3

[0022] As an improvement of the present invention, the oil inlet hole 6 extends through the inner wall of the roller body 2 to above the relative position of the lubricating end plate 5 and the axis of the roller body 2 . The above technical solution can effectively improve the efficiency of lubricating oil entering the lubricating end plate, so that there is enough lubricating grease inside the lubricating end plate for lubricating treatment.

[0023] The remaining features and advantages of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com