A kind of micro pile horizontal static load test device and method

A technology of horizontal static load and test device, which is applied in the test of foundation structure, construction, foundation structure engineering, etc. It can solve the problems of large horizontal displacement of pile top, low strength of pile body, and small bending stiffness of pile body, etc., and achieve balance Easy adjustment, easy installation and disassembly, and stable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

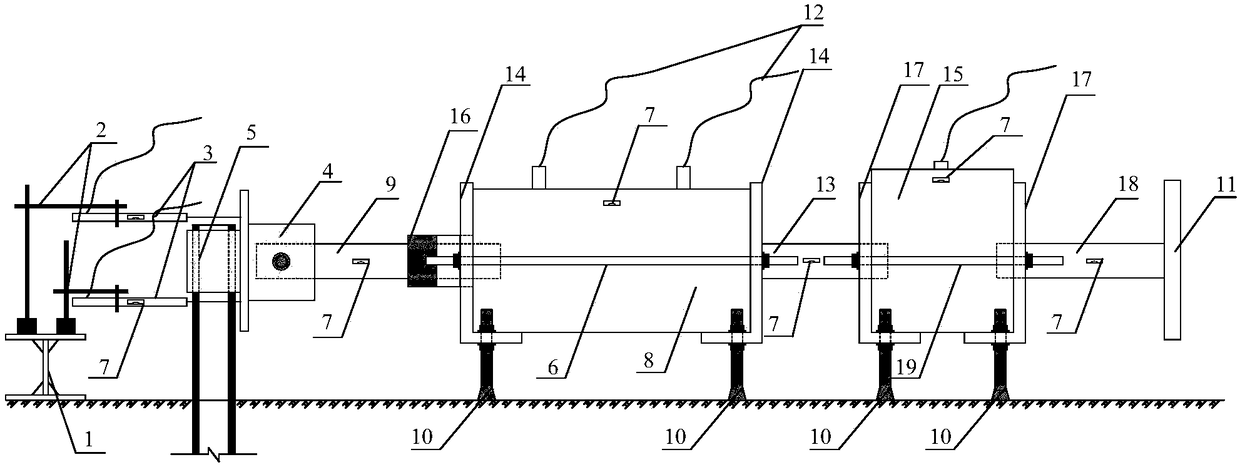

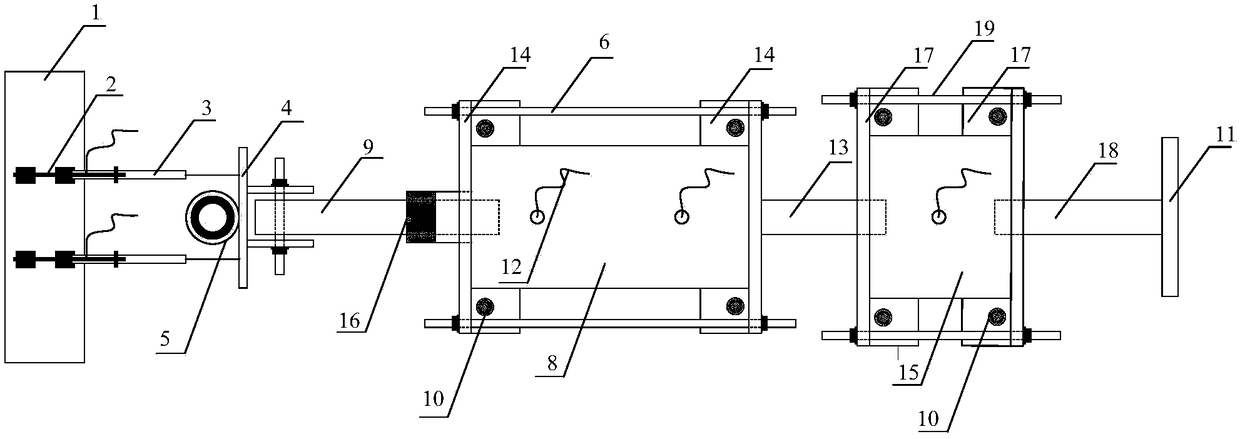

[0046] Embodiment 1 (application of single pile horizontal dead load test device), as figure 1 , 2 Shown:

[0047] 1) Select the reference point according to the test site conditions, set the reference beam 1, the length of the reference beam 1 is determined according to the position of the test pile, as long as possible, but its height-span ratio should not be less than 1 / 40, and the distance between the reference beam 1 and the test pile should not Less than 4 times the diameter of the test pile;

[0048] 2) Set the magnetic base 2 on the reference beam 1;

[0049] 3) Select the pile head fixing nut 5 according to the size of the test pile diameter, weld it with the π-shaped steel plate 4 and fix it on the pile head;

[0050] 4) Pass the steel bar through the reserved hole of the π-shaped steel plate 4 and the reserved hole at the left end of the first force transmission shaft 9, and fix it with nuts on the outside of the π-shaped steel plate 4;

[0051] 5) Pass the two ...

Embodiment 2

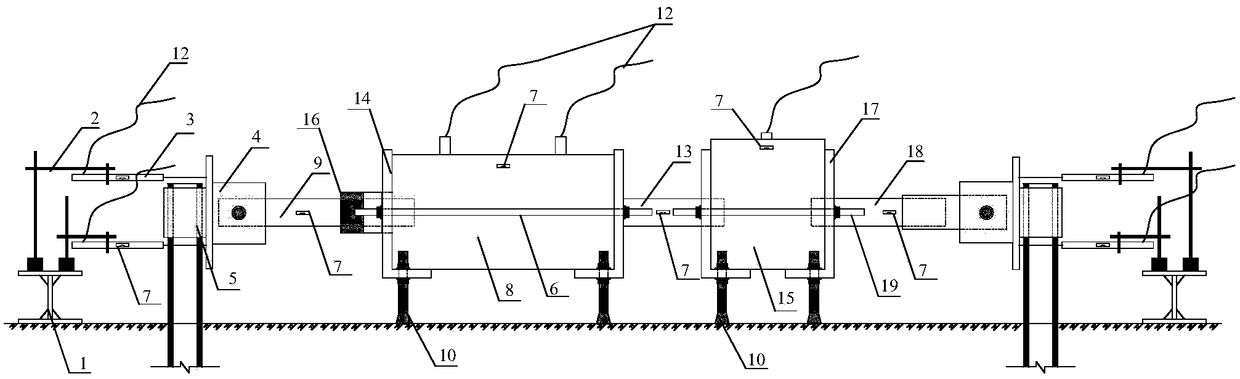

[0060] Embodiment 2 (the application of double pile horizontal dead load test device), as image 3 , 4 Shown:

[0061] 1) Select the reference point according to the test site conditions, set the reference beam 1, the length of the reference beam 1 is determined according to the position of the test pile, as long as possible, but its height-span ratio should not be less than 1 / 40, and the distance between the reference beam 1 and the test pile should be Not less than 4 times the diameter of the test pile;

[0062] 2) Set the magnetic base 2 on the reference beam 1;

[0063] 3) Select the pile head fixing nut 5 according to the diameter of the test pile on the left side, weld it with the π-shaped steel plate 4 and fix it on the pile head;

[0064] 4) Pass the steel bar through the reserved hole of the π-shaped steel plate 4 and the reserved hole at the left end of the first force transmission shaft 9, and fix it with nuts on the outside of the π-shaped steel plate 4;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com