Automatic-rectifying zero-error foundation bolt flanged connection structure

An anchor bolt and connection structure technology, which is applied in the direction of the engine frame, supporting machine, mechanical equipment, etc., can solve the problems of installation error and correct angle installation between the tower and the anchor bolt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

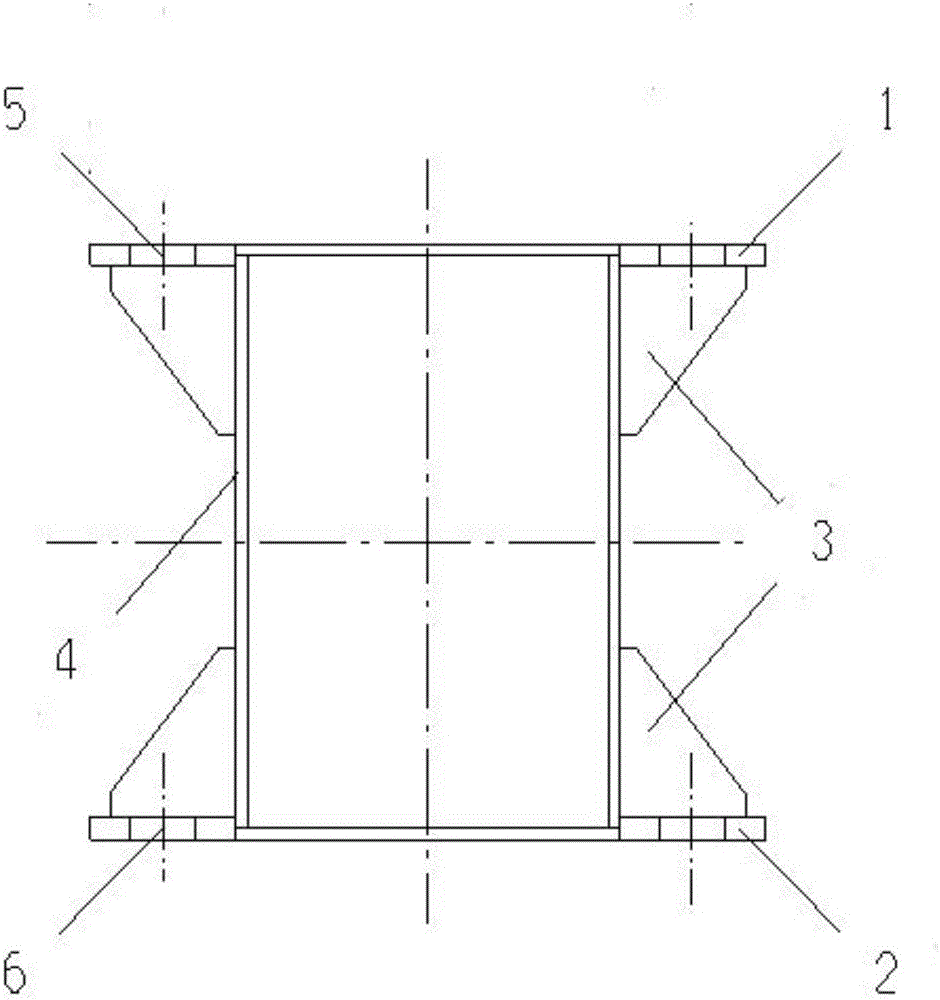

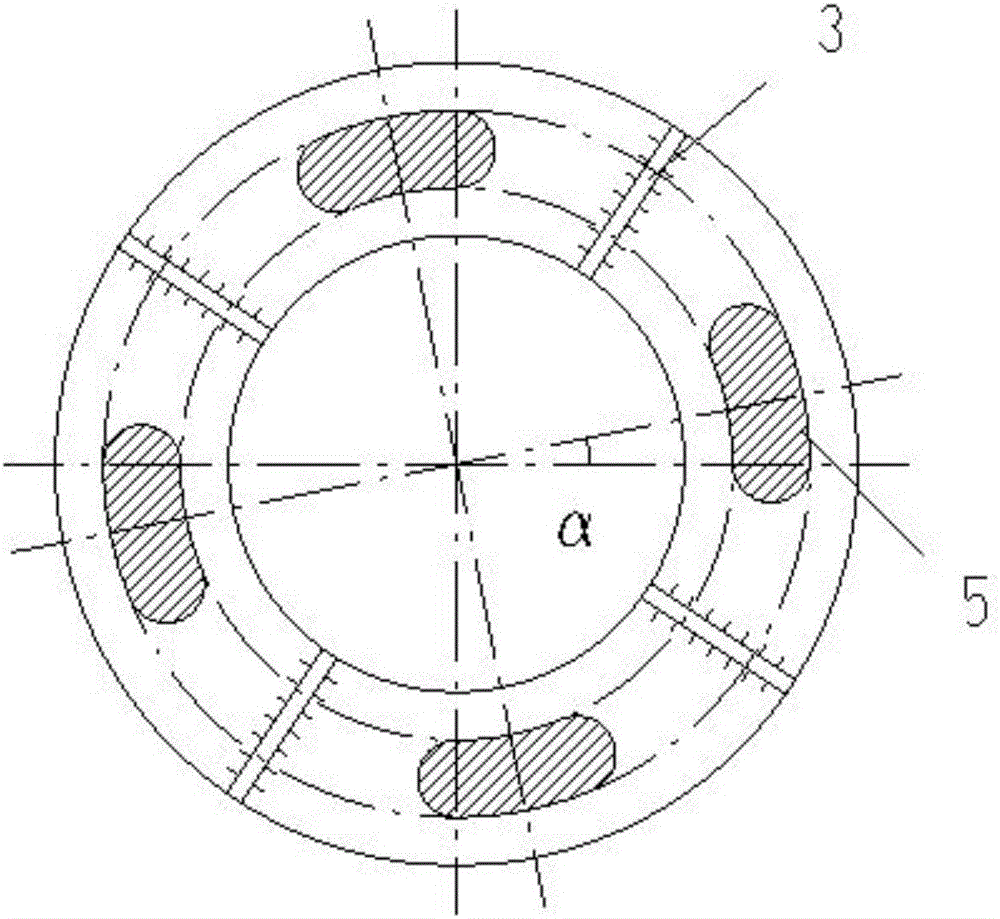

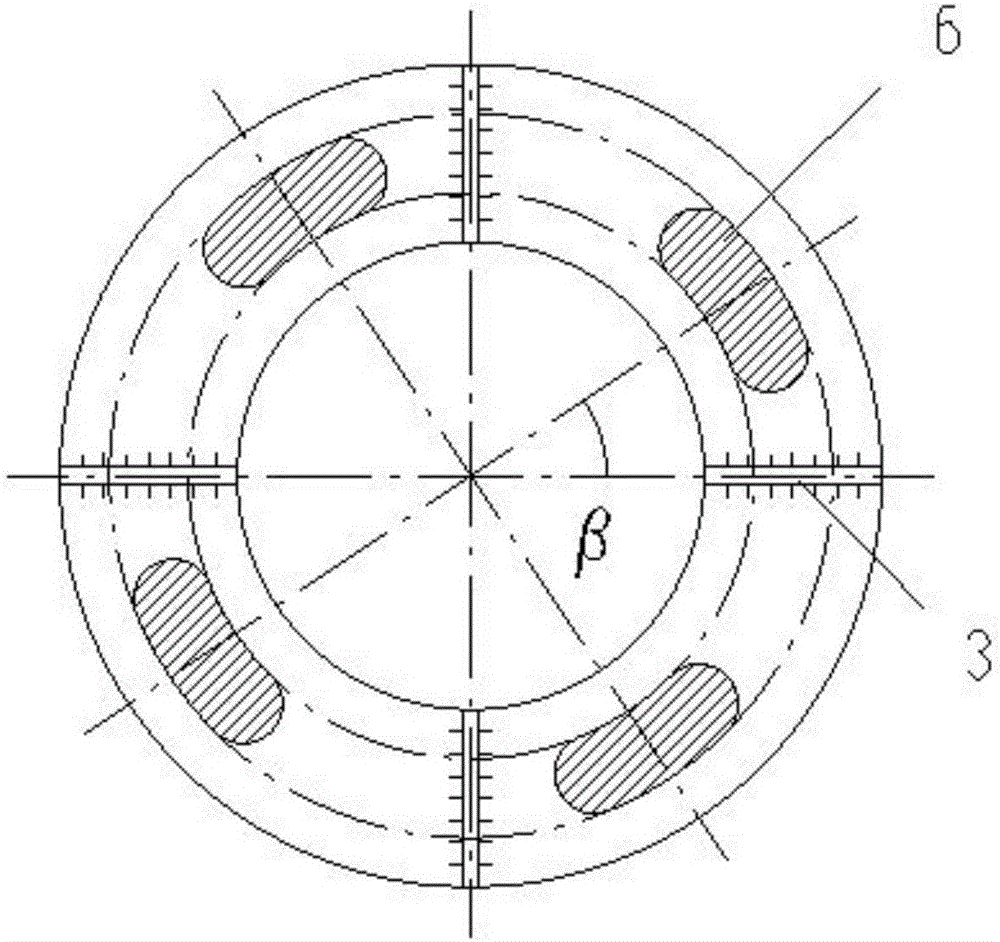

[0022] Such as Figure 1-Figure 3 A self-correcting zero-error anchor bolt flange connection structure shown includes an upper flange 1 connected to the bottom of the pole tower, a steel pipe member 4 integrally connected with the upper flange, and a parallel pipe member integrally connected with the steel pipe member. The lower flange 2 that is fixedly connected with the anchor bolts is processed with a lower flange opening 6 for the anchor bolts to pass through. The lower flange opening is an arc-shaped slot hole. An upper flange opening 5 is processed on the blue plate, and the upper flange opening is an arc slot. It also includes a reinforcement rib 3, the reinforcement rib includes an upper reinforcement rib connected between the steel pipe member and the upper flange, and a lower reinforcement rib connected between the steel pipe member and the lower flange, and the upper reinforcement rib is connected to the upper flange. The openings of the flange are staggered, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com