Elastic floating brake pad

A floating brake, elastic technology, applied in the direction of friction linings, brake types, brake components, etc., can solve the problems of cracks, defects, friction blocks not self-adjusting, unfavorable wear debris and friction heat, etc. Increase the area and volume, solve the eccentric wear of the brake pad, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

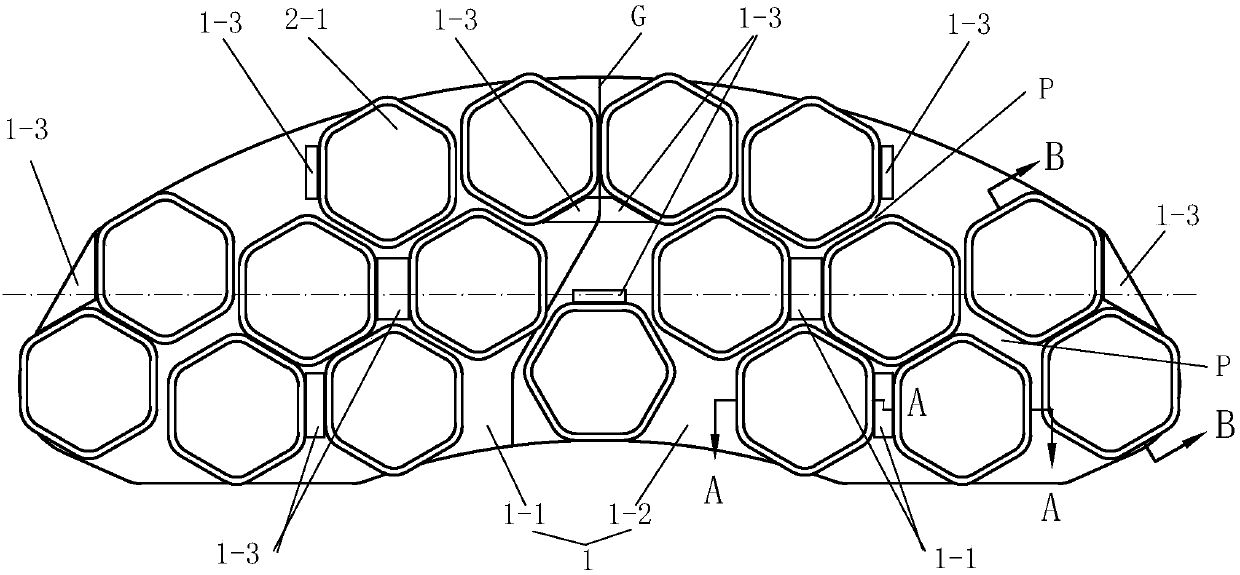

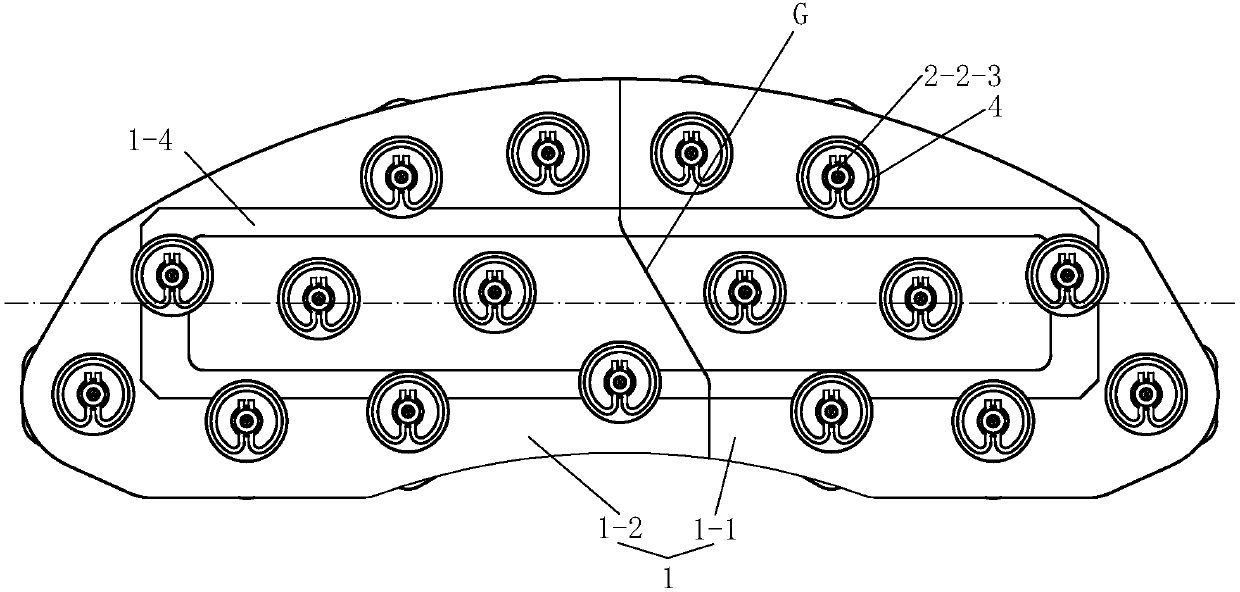

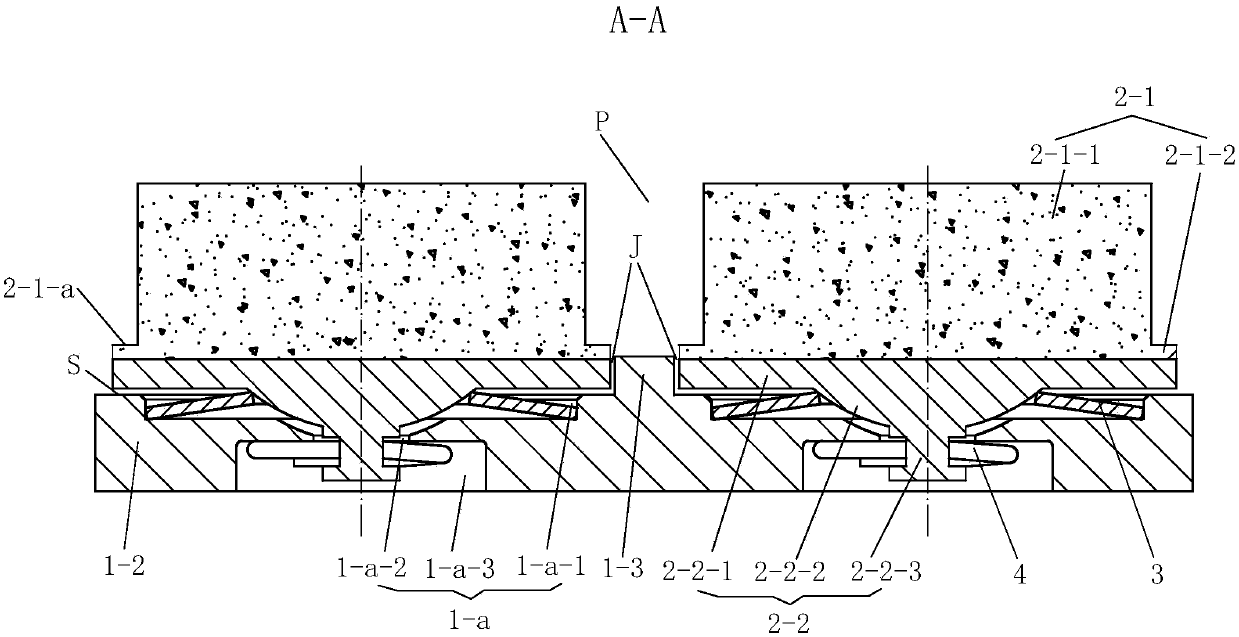

[0024] See Figure 1 to Figure 7 , this embodiment includes a mounting plate 1 and 17 friction blocks 2 arranged on the mounting plate 1, the friction block 2 has a support body 2-2 and a metallurgical powder friction body 2-1 fixed on the support body 2-2, so The friction body 2-1 is a regular hexagonal stepped column. The friction body 2-1 is composed of a friction body 2-1-1 and a friction chassis 2-1-2. The friction chassis 2-1-2 protrudes from the friction body 2-1. 1-1 forms a circle of edge 2-1-a, and the edge 2-1-a is used as a wear degree comparison surface. The shape of the friction main body 2-1-1 and the friction chassis 2-1-2 are similar, and the cross section is hexagonal shape, its six corners are arc angles. The height H of the friction chassis 2-1-2 is 2-5 mm. In specific applications, the height H is set according to user requirements. The ratio of the arc angle R1 of the friction body 2-1 to the length L1 of the opposite side is 0.18-0.22, and the ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com