Angle adjustment device and hydraulic control method for realizing simultaneous construction of equidistant double boreholes

An angle-adjusting device and double-drilling technology, which are applied to drilling equipment and methods, supporting devices, earth-moving drilling and mining, etc., can solve the problem of inability to meet the requirements of efficient drilling construction, limited drilling depth in construction scope, and angle adjustment range of the whole machine. limited and other problems, to achieve the effect of improving the scope of application and operation capacity, wide coverage and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, thereby making a clearer definition of the protection scope of the present invention, below in conjunction with the accompanying drawings and specific implementation The method will describe the present invention in detail.

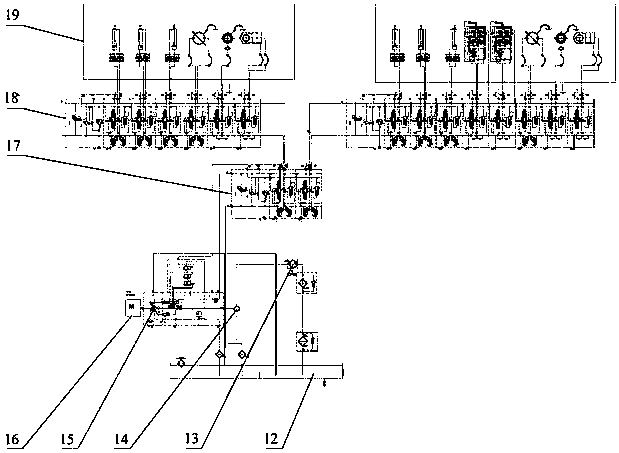

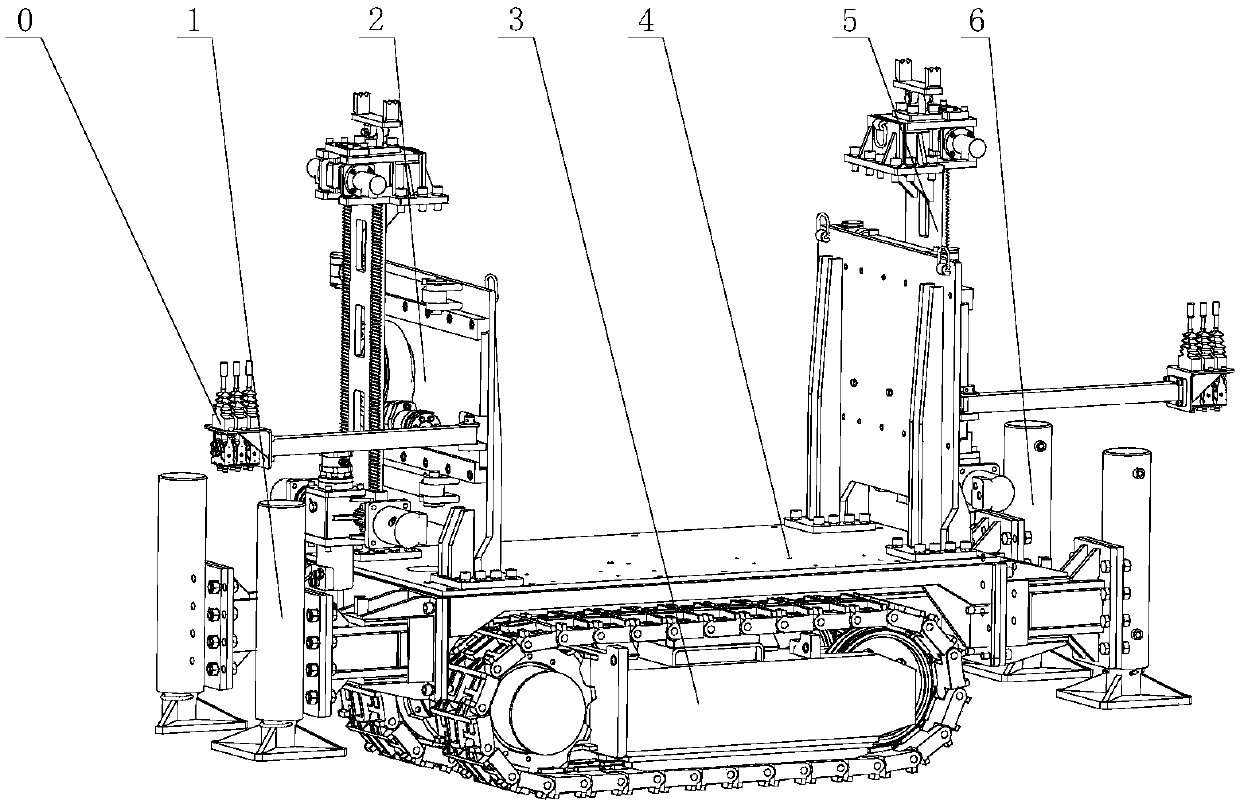

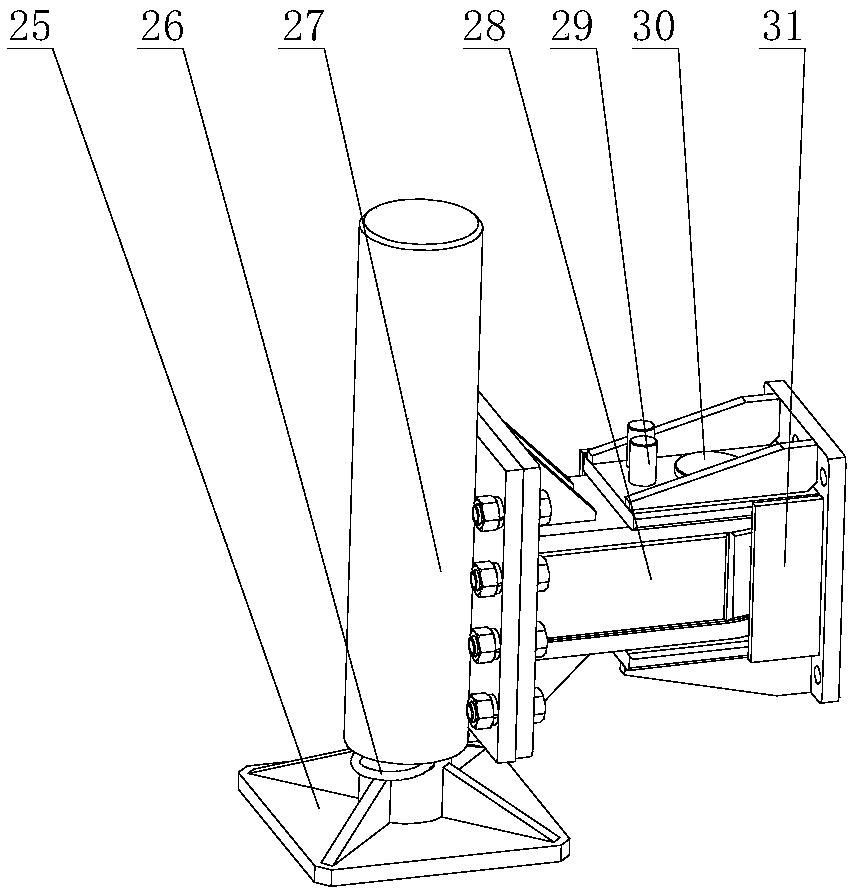

[0039] Such as figure 1 Shown is a schematic diagram of the general assembly of an angle adjustment device for realizing equidistant double drilling construction according to the present invention. , welding car body 4, 2 drill arms 5 and 2 front outriggers 6; wherein, the welding car body 4 is connected with the crawler belt 3 through bolts, and the 2 drilling frame assemblies 2 can be connected to the welding car through bolts Above the two sides of the body 4, the two front outriggers 6 and the two rear outriggers 1 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com