Rotary motor

A technology of rotating electrical machines and rotors, applied in the field of rotating electrical machines, can solve problems such as coil flying out, achieve the effects of preventing accidental flying out, ensuring occupancy, and suppressing the reduction of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

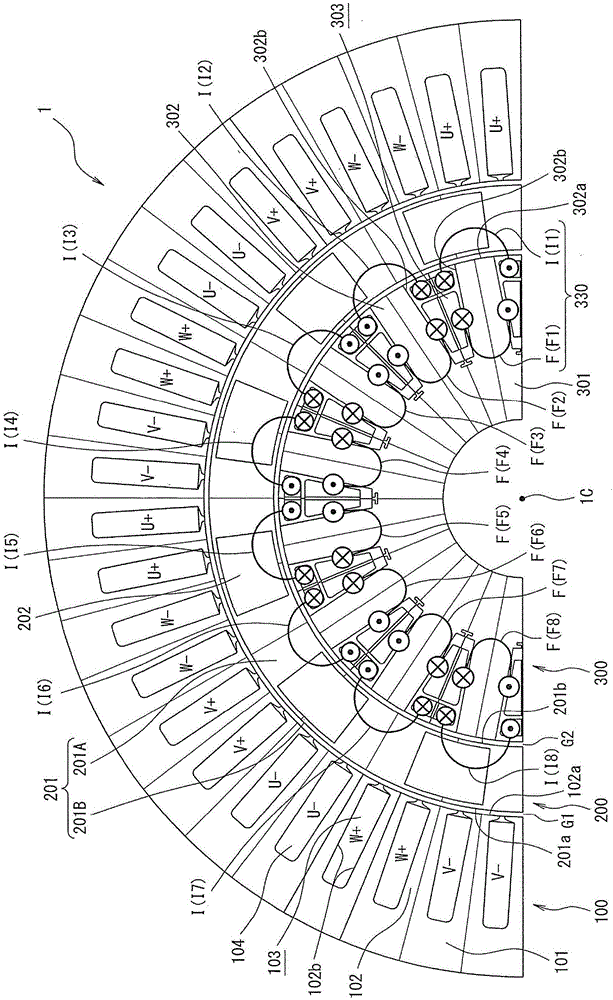

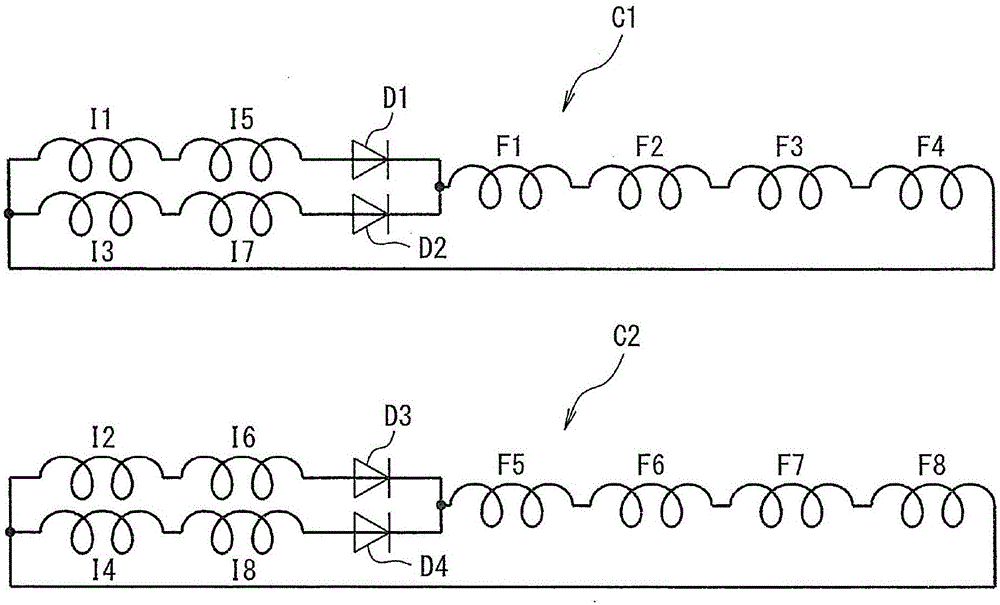

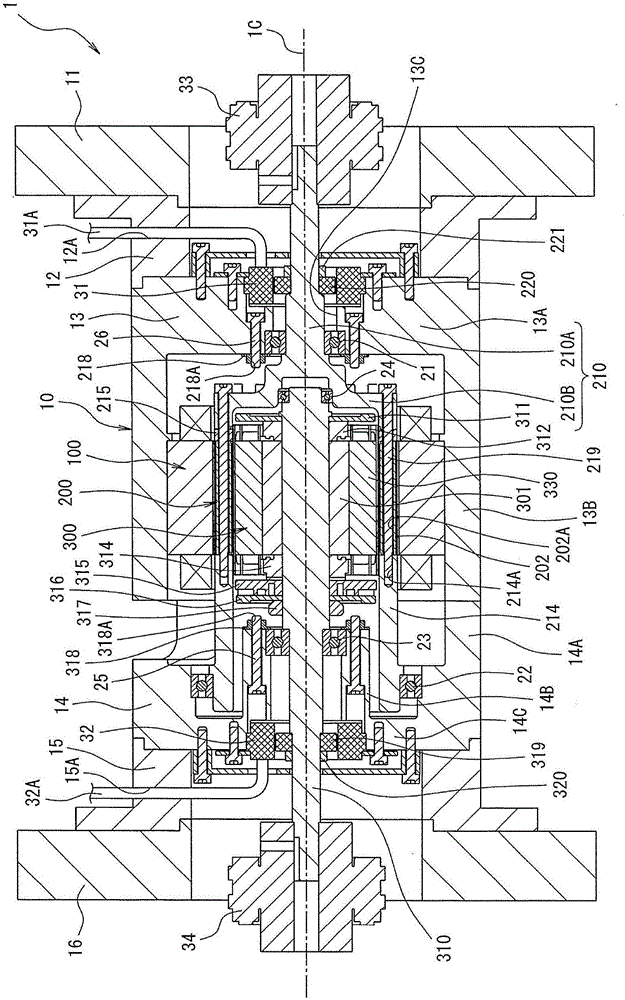

[0041] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Figure 1 to Figure 12 It is a figure explaining the rotating electrical machine which concerns on one Embodiment of this invention.

[0042] exist figure 1 Among them, the rotating electrical machine 1 is constituted as a rotating electrical machine of a double-rotor type, and includes: a stator 100 formed in a cylindrical shape; an outer rotor 200 as a second rotor provided on the rotating shaft 1C side of the stator 100; An inner rotor 300 serving as a first rotor on the rotating shaft 1C side of the rotor 200 . The outer rotor 200 and the inner rotor 300 are respectively supported so as to be relatively rotatable around the rotation axis 1C. also, figure 1 A radial cross-sectional view of 180 degrees (1 / 2) out of 360 degrees of mechanical angle is shown. The inner rotor 300 constitutes a rotor in the present invention.

[0043] The stator 100 includes a stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com