Intermediate driven small-angle oblique deep rotary tilling device

A small-angle, oblique technology, applied in the field of agricultural engineering research, can solve the problems that the cultivation quality of the lower part of the middle box cannot meet the crushing quality requirements, affect the cultivation depth and cultivation quality, and the soil in the middle transmission box is difficult to remove, etc., to achieve improved The ability of burying grass to remove stubble, improving traction performance and reliability, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

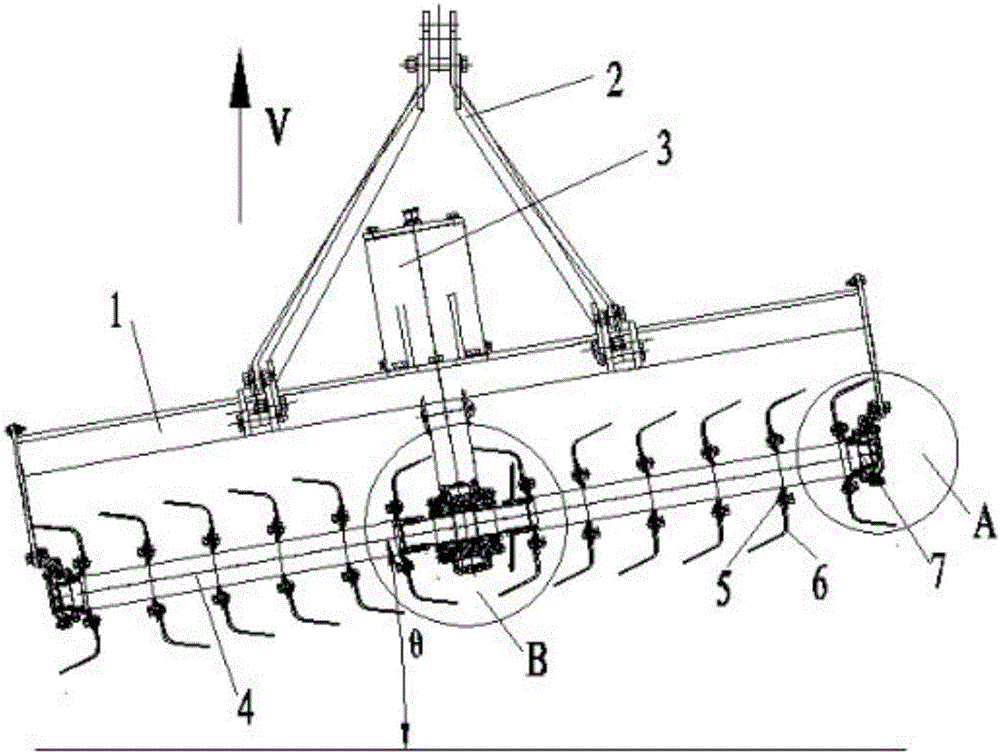

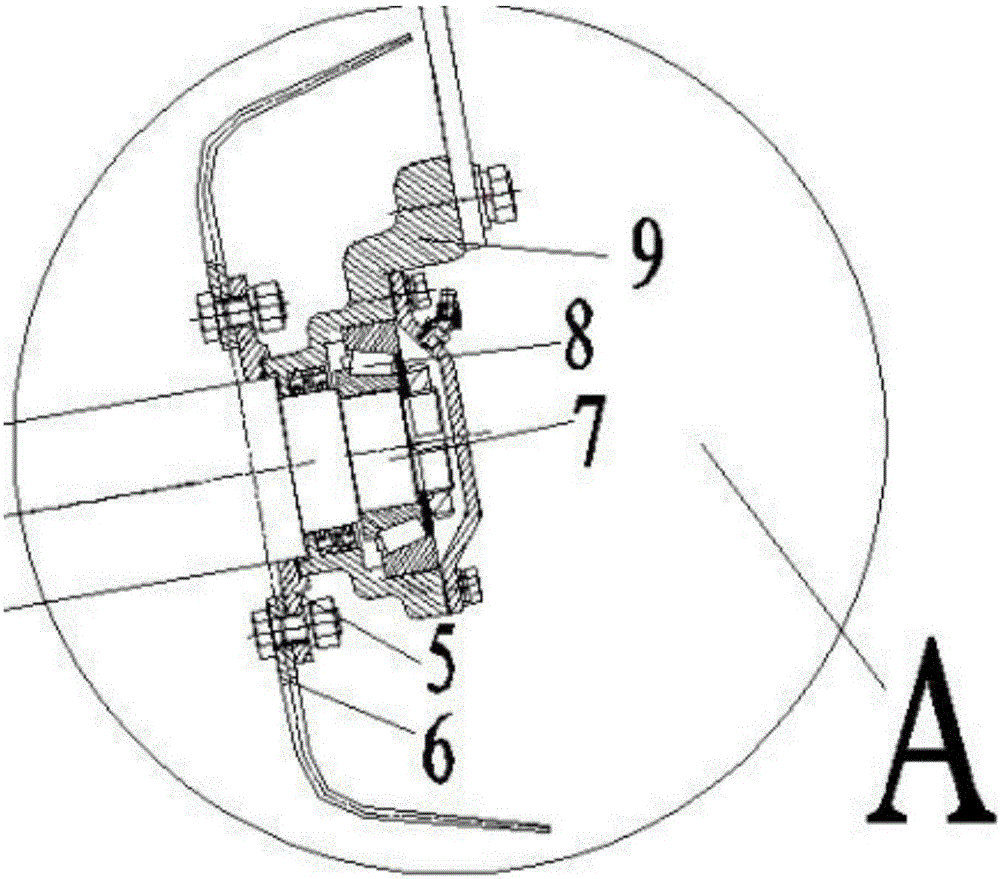

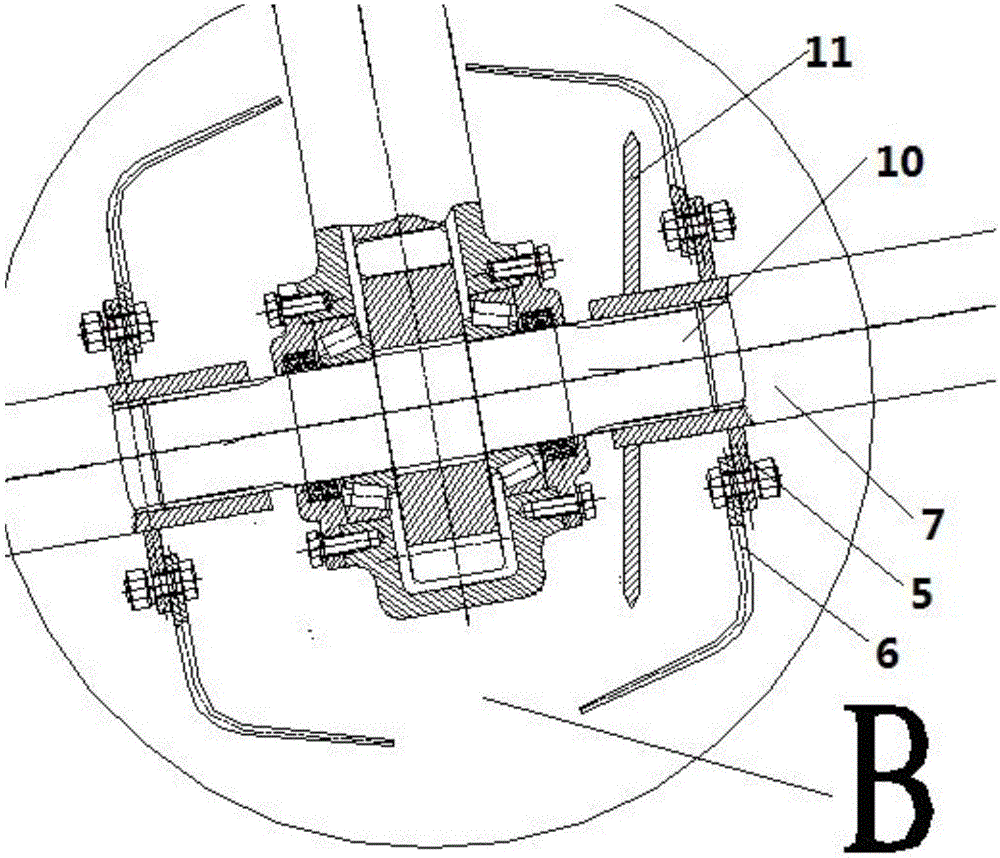

[0027] Such as figure 1 , 2 Shown in and 3 is an embodiment of the small-angle oblique deep rotary tillage device of the intermediate transmission of the present invention, the small-angle oblique deep rotary tiller of the intermediate transmission includes a frame 1, a suspension 2, a gearbox 3 and cutter roller 4; the suspension 2 is connected to the frame 1, the gearbox 3 is located at the center of the frame 1, the output shaft 10 of the gearbox 3 is a spline shaft, and the two sides of the output shaft 10 are respectively connected to the two sides of the cutter One end of the roller 4 is connected, and the other end of the cutter roller 4 is installed in the tapered roller bearing 8 of the bearing seat 9, and the bearing seat 9 is fixed on the inside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com