Method and apparatus for scale prevention, descaling, sterilization and algae extermination of pipelines

A technology for sterilizing algae and anti-scaling, which is applied in the field of descaling methods and devices, pipeline anti-scaling and descaling methods and devices, and can solve problems such as heat energy decline, enterprise shutdown, and malignant accidents, and the achievement rate is reduced and the effective collision rate is reduced. The effect of reducing and preventing scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

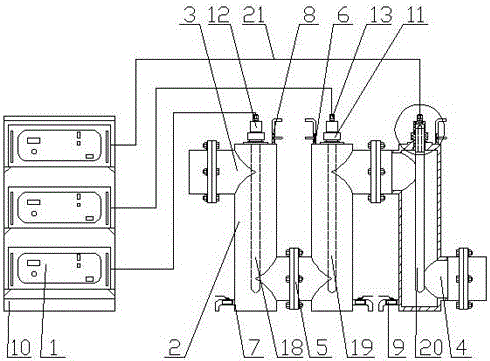

[0019] Depend on figure 1 As shown, the pipeline anti-scaling, descaling, sterilization and algae killing device mainly includes a control host 1, an electrode and a pipe body 2. The pipe body 2 is provided with a water inlet 3 and a water outlet 4. The pipe bodies 2 are arranged in a row. The adjacent pipe bodies 2 are connected by connecting flanges 5. The pipe bodies 2 can be designed in different shapes according to different factory environments. The pipe body 2 of the device is installed in the main pipe or branch of the water system. On the pipe, let all the water flow through the device, which is as close as possible to the protected equipment pipe or the rear end of the water pump.

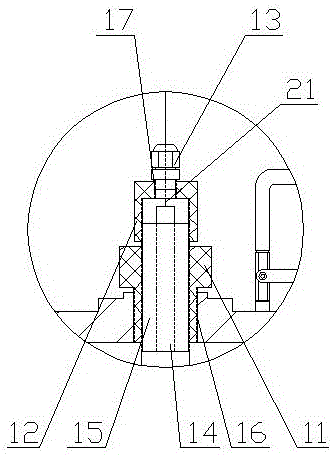

[0020] Depend on figure 2 As shown, the device also includes an insulating sleeve 11, an insulating cap 12 and a waterproof joint 13, the upper end of the electrode is provided with a joint 14, and an insulator 15 is provided outside the joint 14, and the upper end of the pipe body 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com