Method for realizing and maintaining sterile environment of sterile filling isolation bin

A technology of aseptic environment and aseptic filling, which is applied in the direction of water supply equipment, sanitary equipment for toilets, buildings, etc., can solve the problems of non-environmental protection, high use cost, scaling of isolation warehouses, etc., and achieve good sterilization effect and high sterilization efficiency. The effect of high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

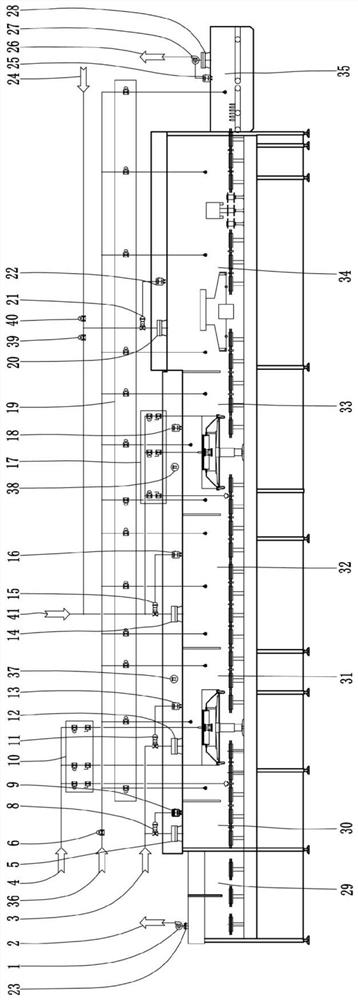

[0047] COP cleaning: Use a cleaning agent to clean the inner surface of the isolation chamber and the outer surface of the device located in the isolation chamber, specifically including washing the isolation chamber with RO water first, then cleaning the isolation chamber with an alkali foam cleaning solution with a mass concentration of 2%, and then cleaning the isolation chamber. Rinse the isolation chamber with RO water to remove the alkali foam cleaning solution, then clean the isolation chamber with an acid foam cleaning solution with a mass concentration of 2%, and finally rinse the isolation chamber with RO water to remove the acid foam cleaning solution. Wherein, when cleaning, the first pneumatic valve 6 and the third control valve group 19 are opened, and the cleaning agent can enter the first pipeline from the third inlet 36, and enter the second pipeline from the first pipeline to enter the isolation chamber to clean the isolation chamber. cleaning.

[0048] CIP c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com