A 150°C-resistant radiation-free, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material and its preparation method

A polyolefin cable material, radiation-free technology, applied in 150°C radiation-free, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material and its preparation, 150°C radiation-free, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable In the field of materials, the effect of oil resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

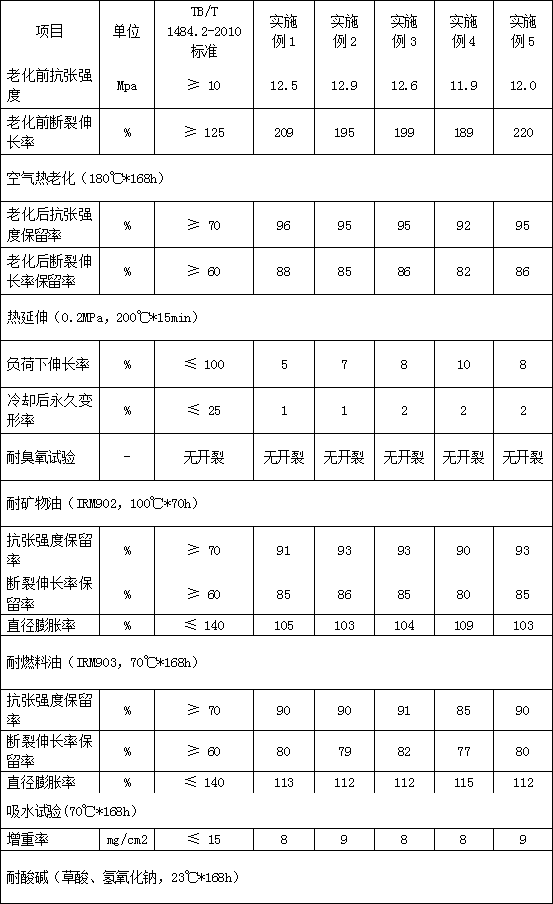

[0043] Examples 1-5: A 150°C-resistant, radiation-free, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material and its preparation method

[0044] 150°C-resistant, radiation-free, oil-resistant, low-smoke, halogen-free, flame-retardant polyolefin cable material, its raw material formula (unit: parts by weight) is shown in Table 1:

[0045] Table 1 Formula of 150℃ radiation-free, oil-resistant, low-smoke, halogen-free and flame-retardant polyolefin cable compound

[0046] raw material

Example 1

Example 2

Example 3

Example 4

Example 5

Ethylene-vinyl acetate copolymer

30

25

38

31

25

PVC rubber

20

17

10

15

15

High-density polyethylene

30

33

32

28

35

Copolyfluorosilicone rubber

8

10

8

15

10

Compatibilizer

12

15

12

11

15

Halogen-free flame retardant

100

80

120

100

90

Vulcanizing agent

1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap