Preparation methods of novel cross-linking agent and cross-linked polybenzimidazole proton exchange membrane

A technology of polybenzimidazole membrane and proton exchange membrane, which is applied in the field of fuel cell membrane electrode assembly, can solve the problems of unsuitability for industrialization and inability to prepare cross-linked membranes, and achieve simple cross-linking process, improved mechanical properties and oxidation stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

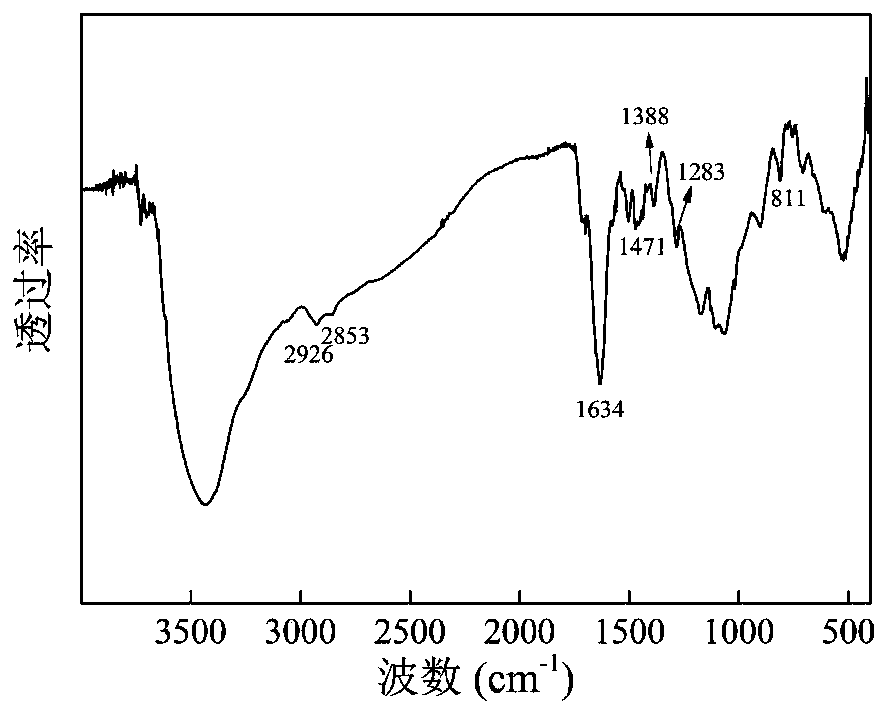

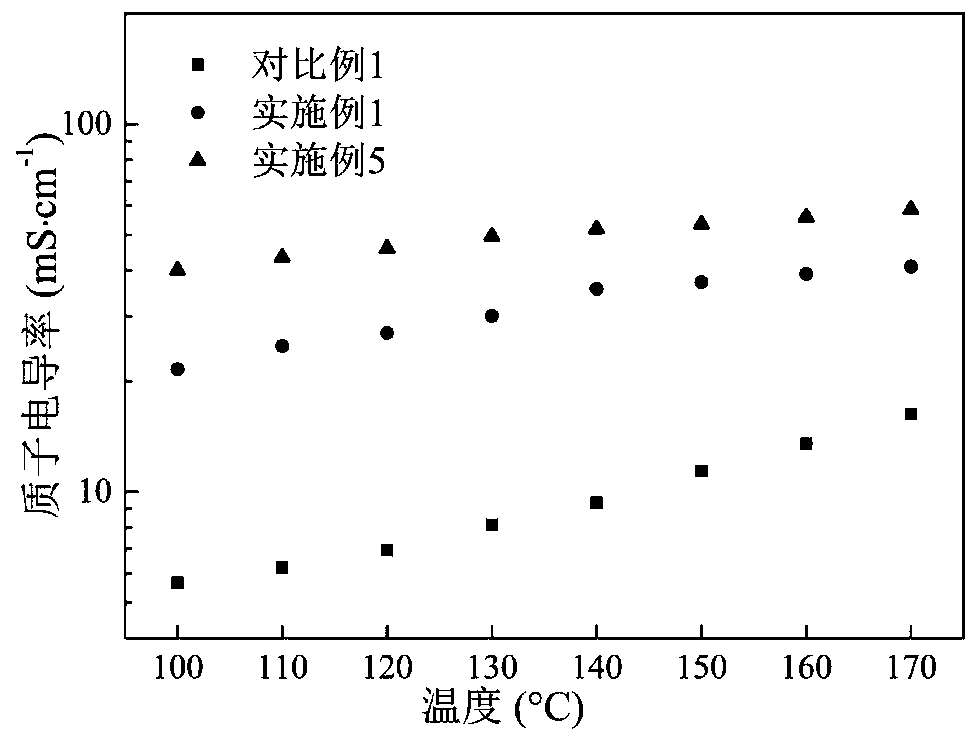

[0037] First 2.14g tetraaminobiphenyl and 16.0g phosphorus pentoxide and 50.0g polyphosphoric acid are added in the there-necked flask with stirring and condensing reflux device, N 2 In the atmosphere, stir at 140°C for 5 hours, add 4.58g of methyl bromomethylbenzoate, after stirring for 1 hour, the solution turns from brown to green, add deionized water to the mixed solution, a yellow-green solid precipitates, filter the solid The precipitate was washed and dried to obtain a crosslinking agent. Add the cross-linking agent into N,N-dimethylformamide, reflux for 3 hours, and filter to obtain a clear cross-linking agent solution. Soak the polybenzimidazole film in the above cross-linking agent solution at a temperature of 60° C., take it out after soaking for 3 hours, wash it, and dry it to obtain a cross-linked polybenzimidazole film.

Embodiment 2

[0039] First 2.14g tetraaminobiphenyl and 48.0g phosphorus pentoxide and 60.0g polyphosphoric acid are added in the there-necked flask with stirring and condensing reflux device, N 2 In the atmosphere, stir at 160°C for 10 h, add 2.29 g of methyl bromomethylbenzoate, and stir for 2 h, the solution turns from brown to green, add deionized water to the mixed solution, a yellow-green solid precipitates, filter the solid The precipitate was washed and dried to obtain a crosslinking agent. Add the cross-linking agent to N,N-dimethylacetamide, condense and reflux for 4 hours, and filter to obtain a clear filtrate, which is used as a cross-linking agent solution. Soak the polybenzimidazole film in the above cross-linking agent solution at a temperature of 70° C., take it out for washing after soaking for 4 hours, and obtain a cross-linked polybenzimidazole film after drying.

Embodiment 3

[0041] First 2.14g tetraaminobiphenyl and 64.0g phosphorus pentoxide and 100.0g polyphosphoric acid are added in the there-necked flask with stirring and condensing reflux device, N 2 In the atmosphere, stir at 150°C for 8 hours, add 2.29g of methyl bromomethylbenzoate, stir for 3 hours, the solution turns from brown to green, add deionized water to the mixed solution, a yellow-green solid precipitates, filter The solid precipitate was washed and dried to obtain a crosslinking agent. Add the cross-linking agent to N-methylpyrrolidone, condense and reflux for 5 hours, and filter to obtain a clear filtrate as the cross-linking agent solution. Soak the polybenzimidazole film in the above crosslinking agent solution at a temperature of 80° C., take it out for washing after soaking for 5 hours, and obtain a crosslinked polybenzimidazole film after drying.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap