Exhausted gas filter

An exhaust filter and filter box technology, which is applied to exhaust devices, machines/engines, mufflers, etc., can solve the problems of easy loosening and falling off of mufflers, environmental pollution, inability to effectively filter black smoke particles, etc., to improve exhaust purification. effect, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

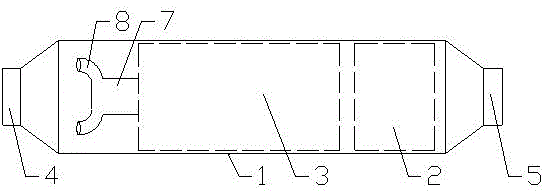

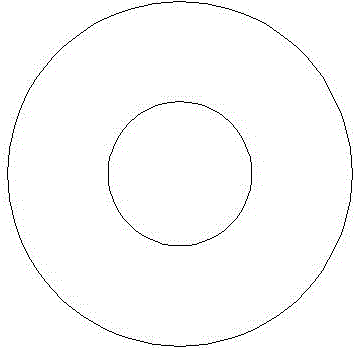

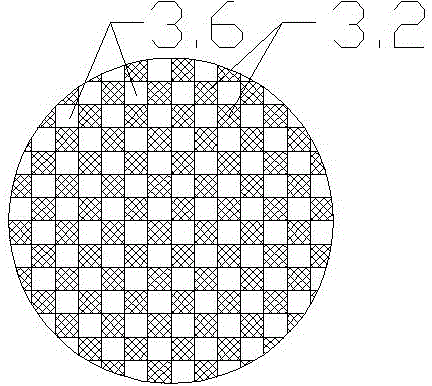

[0036] see Figure 1-6 , the present invention relates to an exhaust gas filter, which comprises a filter box 1, a purifier 2 and a ceramic honeycomb carrier 3, the left end of the filter box 1 is an exhaust gas inlet 4, and the right end is an exhaust gas outlet 5, the purifier 2 and the ceramic honeycomb carrier 3 is set in the filter box 1, the ceramic honeycomb carrier 3 is close to the tail gas inlet 4, the purifier 2 is close to the tail gas outlet 5, the filter box 1 is in the shape of a round tube, and the ceramic honeycomb carrier 3 is connected to the inner wall of the filter box 1 Correspondingly, the ceramic honeycomb carrier 3 is densely covered with air holes 3.1 along the axial direction, one end of the air holes 3.1 is an opening 3.6, and the other end is provided with a sealing surface 3.2, the sealing surface 3.2 and the opening 3.6 are arranged at intervals, and the adjacent The two pores 3.1 are provided with a partition wall 3.3, and the partition wall 3.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Number of holes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com