Electric cabinet fixed connecting equipment

A technology for power cabinets and equipment, applied in the field of electric power, can solve the problems of difficult operation, difficult to control the speed of screwing in the force of the side reserved holes, and positive operation, so as to avoid space restrictions and facilitate efficient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

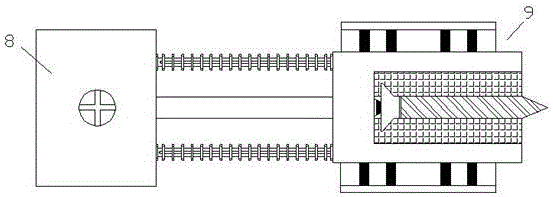

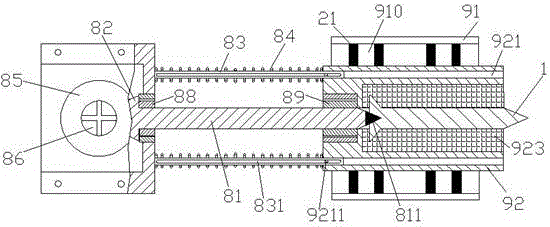

[0011] Combine below Figure 1-4 The present invention will be described in detail.

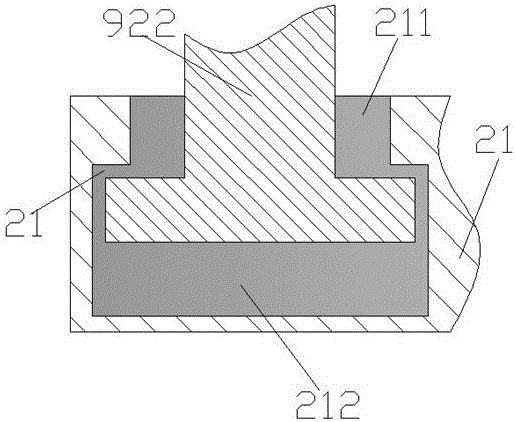

[0012] A power cabinet fixing device according to an embodiment of the present invention, which is used to screw in the fixing part from the side relative to the direction facing the operator, including a locking and positioning part (9) and an executing part (8 ), wherein the locking and fixing part includes a fixing base (91) and a fixing base (92), and the bottom of the fixing base (92) is provided with a sliding foot (922) for It is in contact with the rubber pad (21) provided in the slideway (910) of the retention base (91), and the rubber pad (21) includes two sides of the sliding foot (922) for The elastic clamping part (211) clamped and fixed by the sliding foot (922) and the elastic support part located on the bottom side of the sliding foot (922) for adjusting the longitudinal position of the sliding foot (922) (212); the fastener base (92) includes an elastic retainer (923) in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com