Gravity center type structural surface occurrence measuring instrument

A technology for measuring instruments and structural surfaces, applied in the directions of instruments, measuring devices, measuring angles, etc., can solve problems such as slow measurement speed, and achieve the effect of accurate measurement and fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

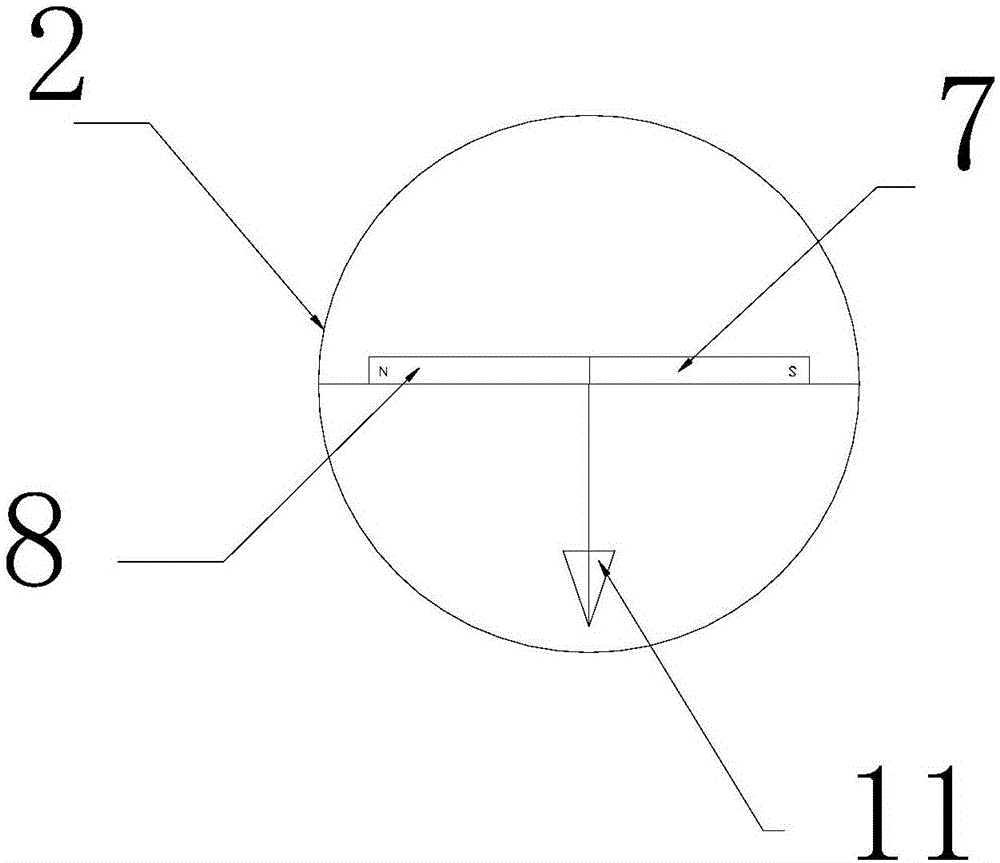

[0033] Put the center of gravity measuring instrument on the structural surface flat on the structural surface, and when the instrument is stable, the position of the south needle 7 and the position of the central partition 1

[0034] Such as Figure 4 As shown, the relative angle scale pointed by the south needle 7 in the figure is 80 degrees, that is, the true inclination azimuth is 80 degrees.

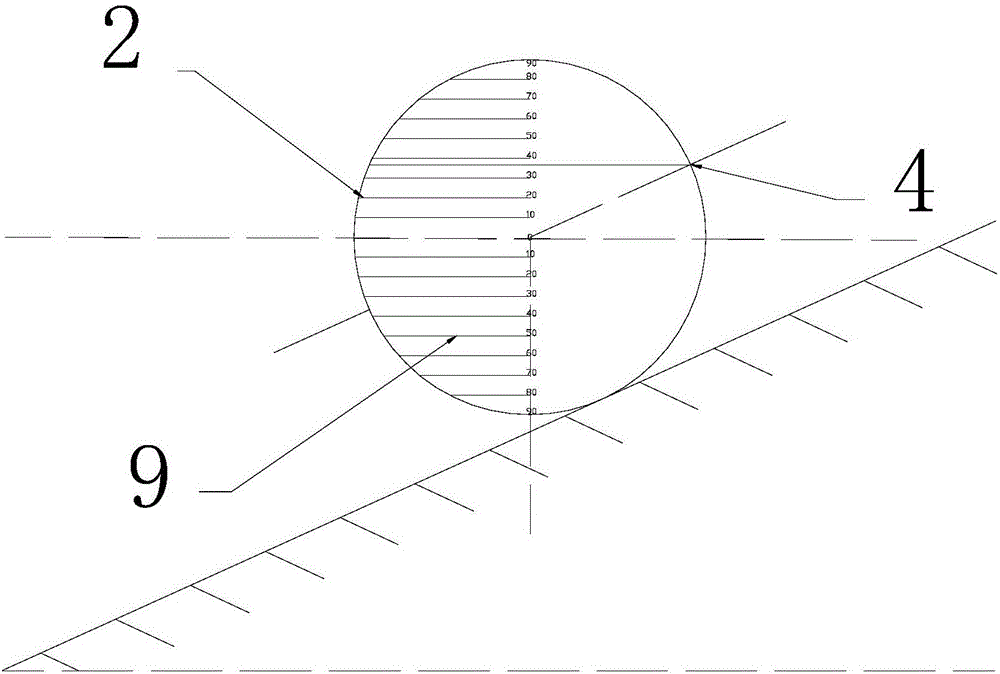

[0035] After the instrument is stabilized, the relative position relationship between the spherical shell and the middle plane 4 is as follows: Figure 5 As shown, at this time, the middle plane 4 corresponds to the scale line with an inclination angle of 20 degrees, so the true inclination angle of the structural surface is 20 degrees.

Embodiment 2

[0037] Put the center of gravity measuring instrument on the structural surface flat on the structural surface, and when the instrument is stable, the position of the south needle 7 and the position of the central partition 1

[0038] Such as Figure 6 As shown, the relative angle scale pointed by the south needle 7 in the figure is 210 degrees, that is, the true inclination azimuth is 210 degrees.

[0039] After the instrument is stabilized, the relative position relationship between the spherical shell and the middle plane 4 is as follows: Figure 7 As shown, at this time, the middle plane 4 corresponds to the scale line of the inclination angle of 40 degrees, so the true inclination angle of the structural surface is 40 degrees.

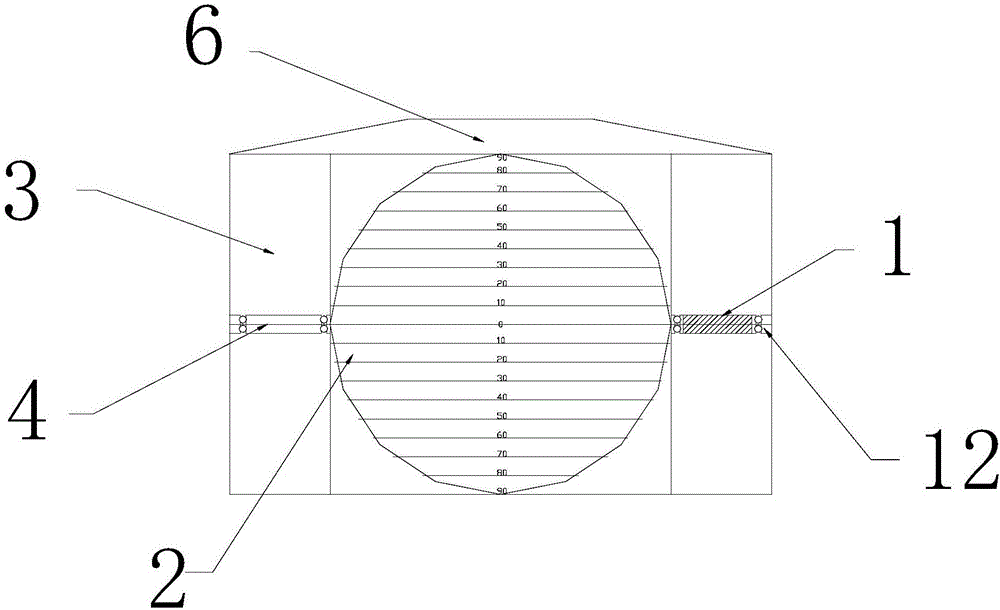

[0040] Such as figure 1 and figure 2 As shown, the center of gravity type structural surface occurrence measuring instrument of the present application includes a frame 3, a central partition 1, and a spherical compass 2. The frame 3 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com