Second-stage self-cleaning type stirring device

A stirring device and self-cleaning technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve the problems of poor operation efficiency of mixing equipment, failure to meet customer needs, low mixing efficiency, etc., and achieve structural Simple, high-efficiency mixing and dispersing operations, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described below.

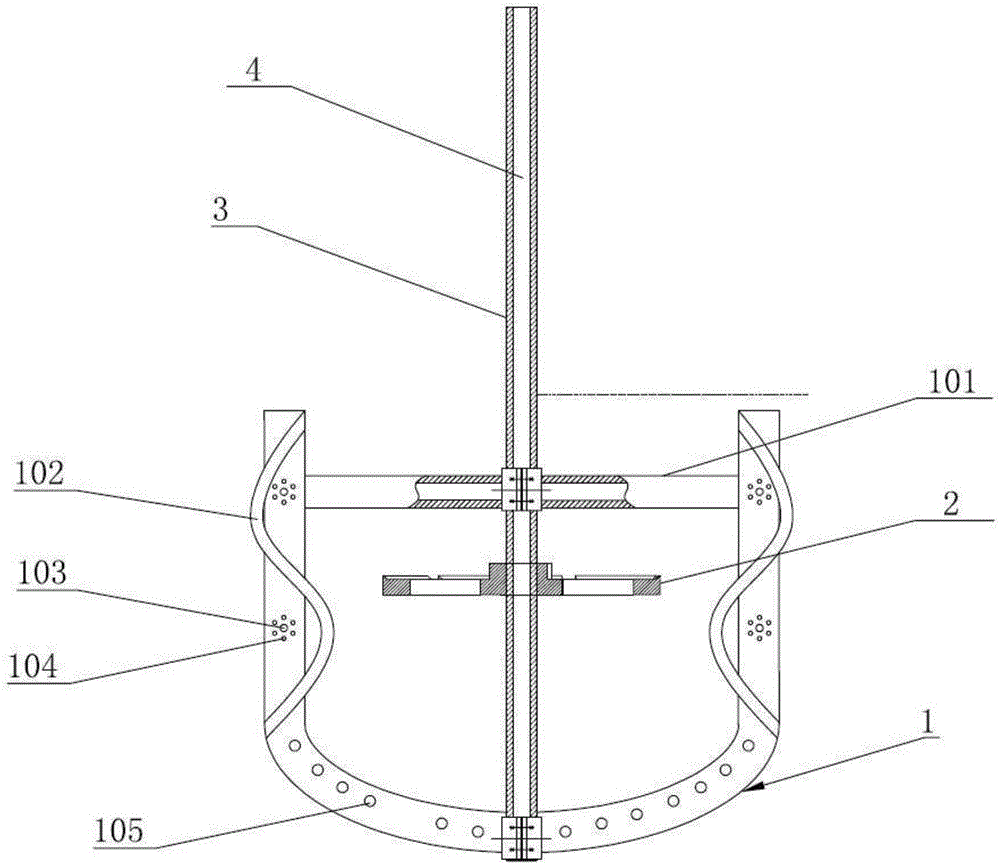

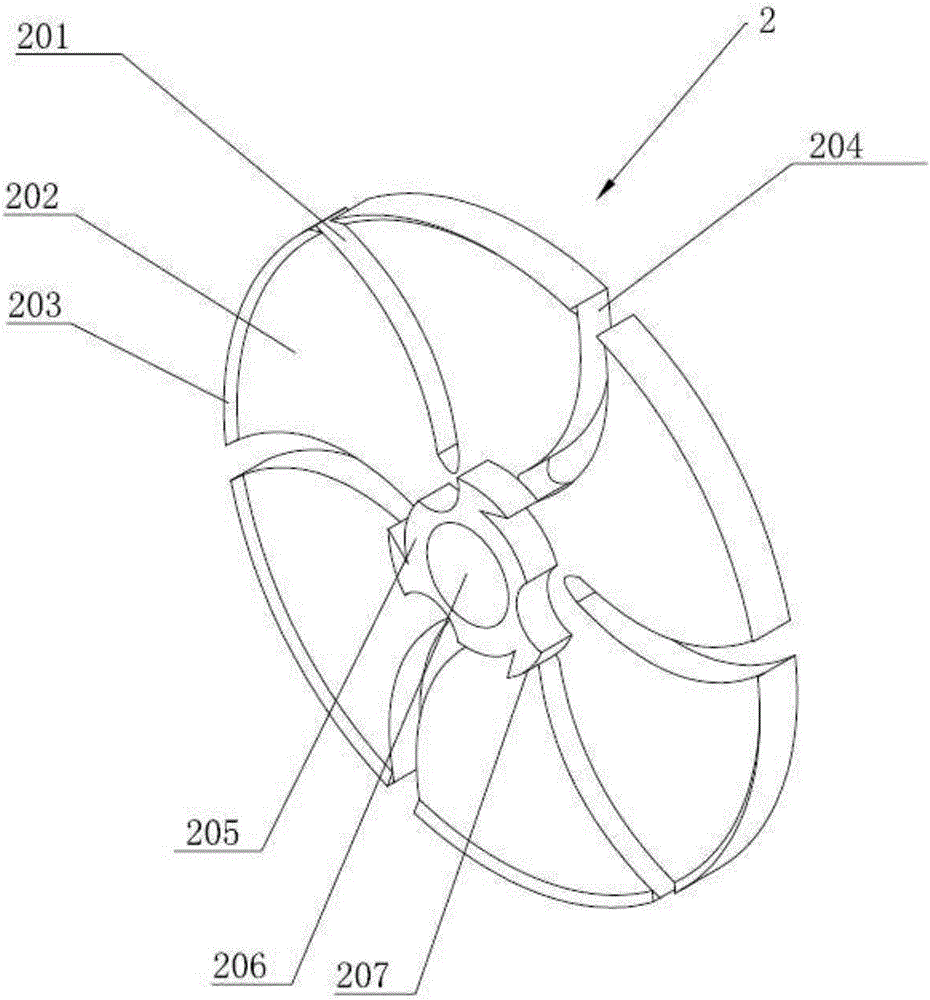

[0017] Such as figure 1 , figure 2 As shown, the two-stage self-cleaning stirring device includes a rotating shaft 3, one end of the rotating shaft 3 is connected to the output end of the drive mechanism, and the other end of the rotating shaft 3 is connected to the stirring blade 1 through the connecting plate 101, and the rotating shaft 3 and the connecting plate 101 is provided with a liquid circulation cavity 4 for inputting cleaning liquid, and a cavity communicating with the liquid circulation cavity 4 is opened on the stirring blade 1, and a first cleaning hole 103 and a plurality of first cleaning holes 103 and a plurality of first cleaning holes 103 are provided along the outer wall of the stirring blade 1. The second cleaning hole 104 and the third cleaning hole 105 , the diameter of the first cleaning hole 103 is larger than that of the second cleaning hole 104 , and the second cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com