A flexible planar rolling tool with measurable pressure

A rolling tool, flexible technology, applied in the field of flexible plane rolling tool, can solve the problem of uncontrollable rolling force, achieve the effect of reducing impact and avoiding vibration of machine tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

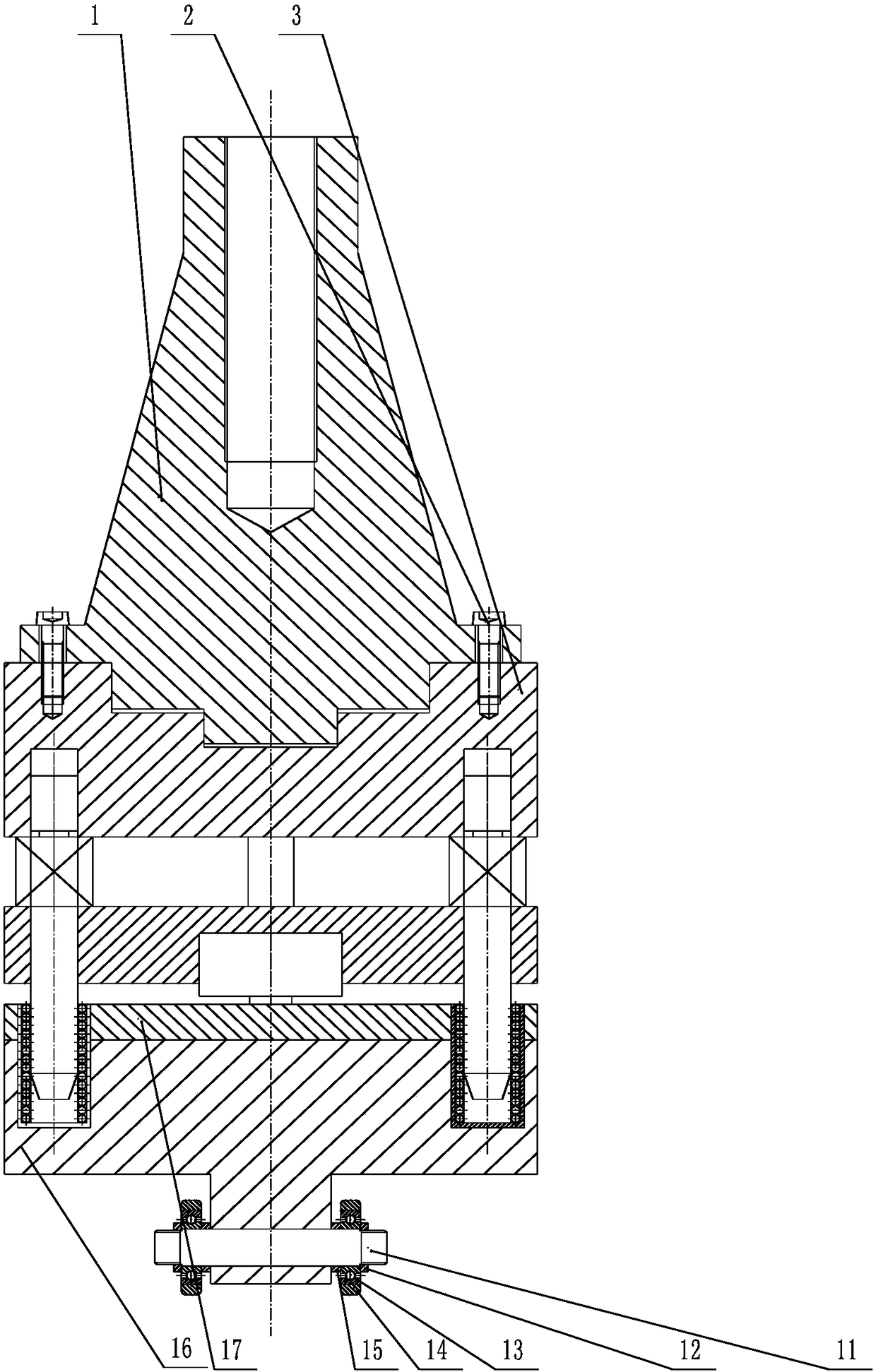

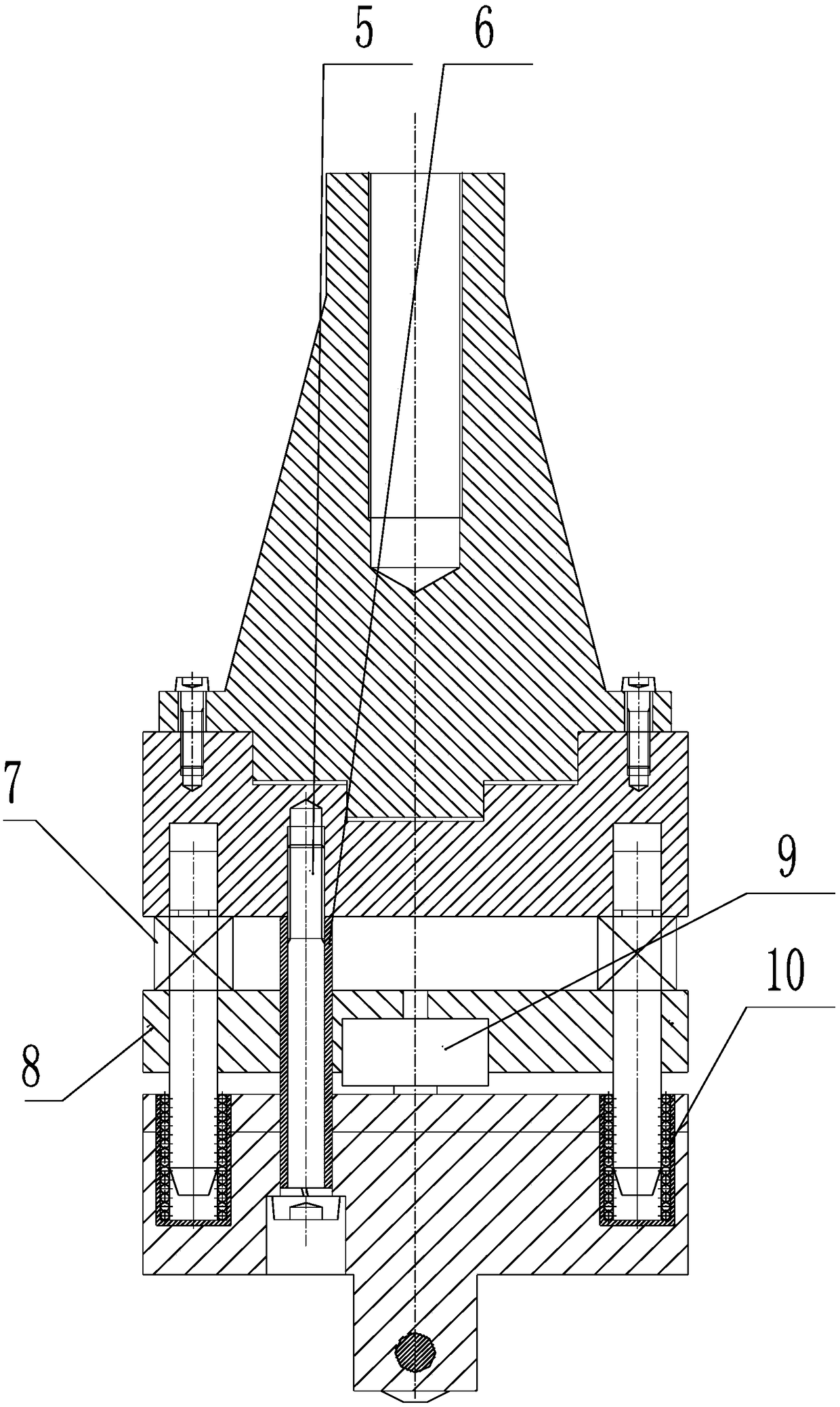

[0027] refer to Figure 1 to Figure 9 , a flexible plane rolling cutter with measurable pressure, comprising a handle 1 and a cutter head, the upper end of the handle 1 is provided with a threaded hole connected to the main shaft of the machine tool, and the cutter head includes a handle connecting block 3, with The force sensor 9 for detecting the rolling force of the machined surface, the sensor fixing seat 8, the roller assembly and the flexible guide assembly, the knife handle connecting block 3 is located below the knife handle 1 and is fixedly connected with the knife handle 1, the sensor The fixing seat 8 is located below the handle connecting block 3 and has a gap with the connecting block 3;

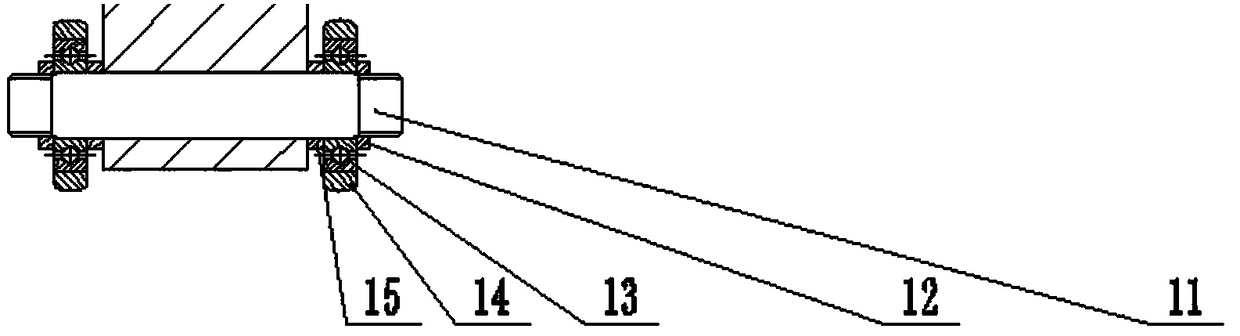

[0028] The roller assembly includes a roller mounting seat, two rollers 14 and a roller mounting shaft 11, the roller mounting seat is T-shaped, the lower end...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap