Fastening device for comb elements on a circular comb

A technology of circular combs and components, applied in deburring devices, combers, textiles and papermaking, etc., can solve the problems of collision, distance affecting maintenance, disadvantage, etc., to ensure fixed, fast assembly and disassembly, and low weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

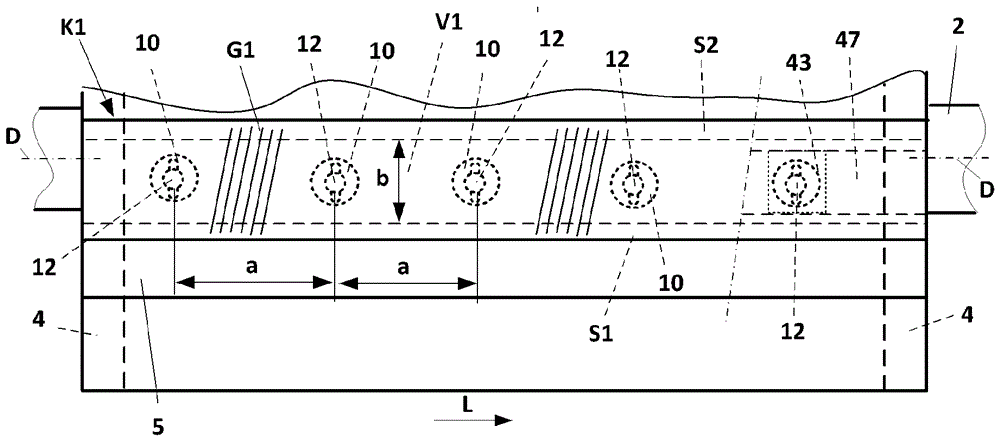

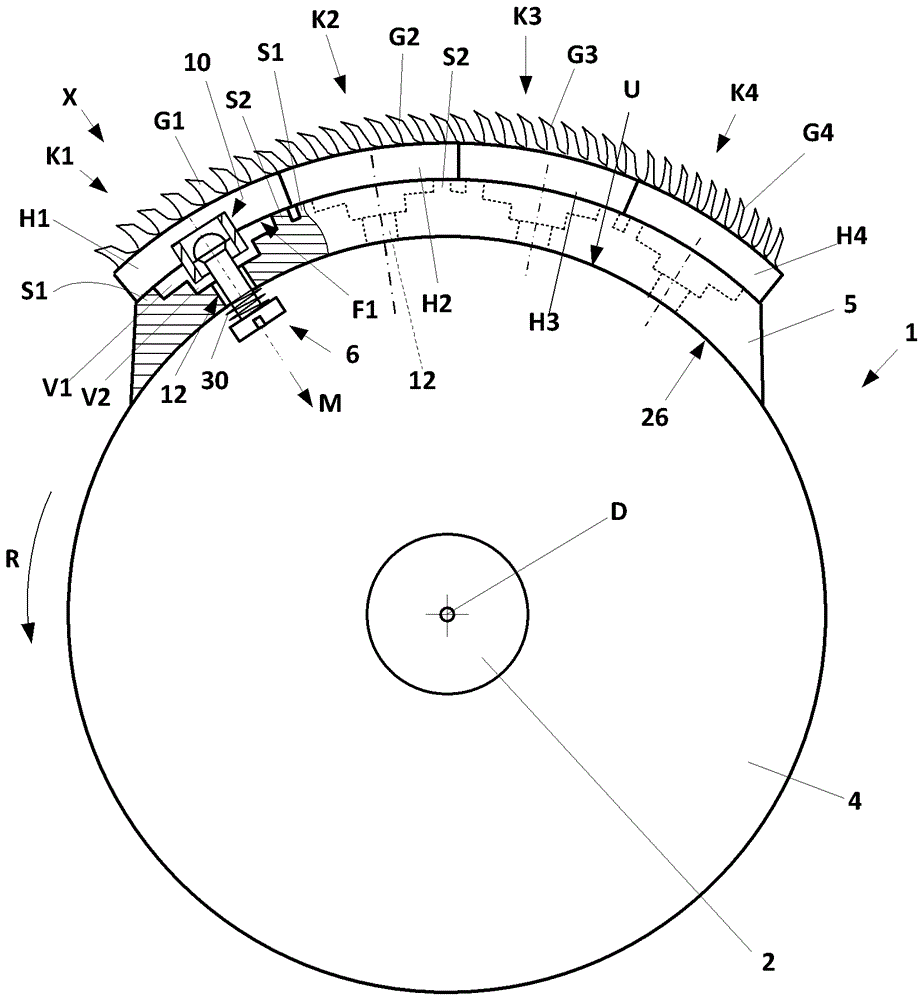

[0034] figure 1 A circular comb 1 is shown having a circular comb shaft 2 on which two flanges 4 are mounted at a distance from each other in a rotationally fixed manner. This also from figure 2 based on the figure 1 This is especially evident in the detail view X of . A base body 5 is fastened to part of the circumference of the flange 4 and, on its circumferential surface U, the base body supports a plurality of comb elements K1 to K4 positioned one behind the other. In the present example, the comb elements K1-K4 have holding bars H1-H4 to which the clothing elements G1-G4 are respectively fastened. The clothing elements G1-G4 can be fastened to the respective holding bars H1-H4 via laser welds, for example as shown and described in published EP 2650414 A1. However, other types of fastening are also possible.

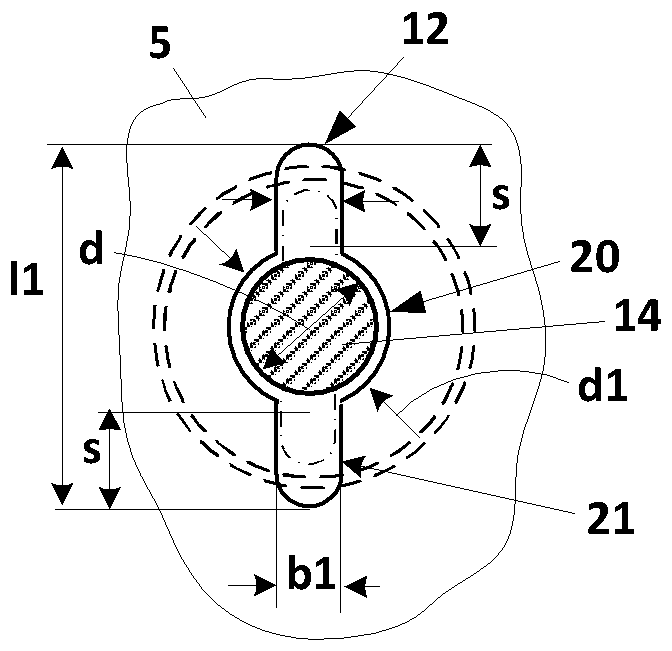

[0035] An exemplary embodiment of the fastening of the front comb element K1 according to the invention is in figure 1 shown in , and in image 3Shown in enl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com