Top-drive guide rail assembly and top-drive guide rail system

A technology of top drive guide rails and components, which is used in earth-moving drilling, support devices, drilling equipment, etc., to achieve the effect of ensuring stability, stable rail connection, and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

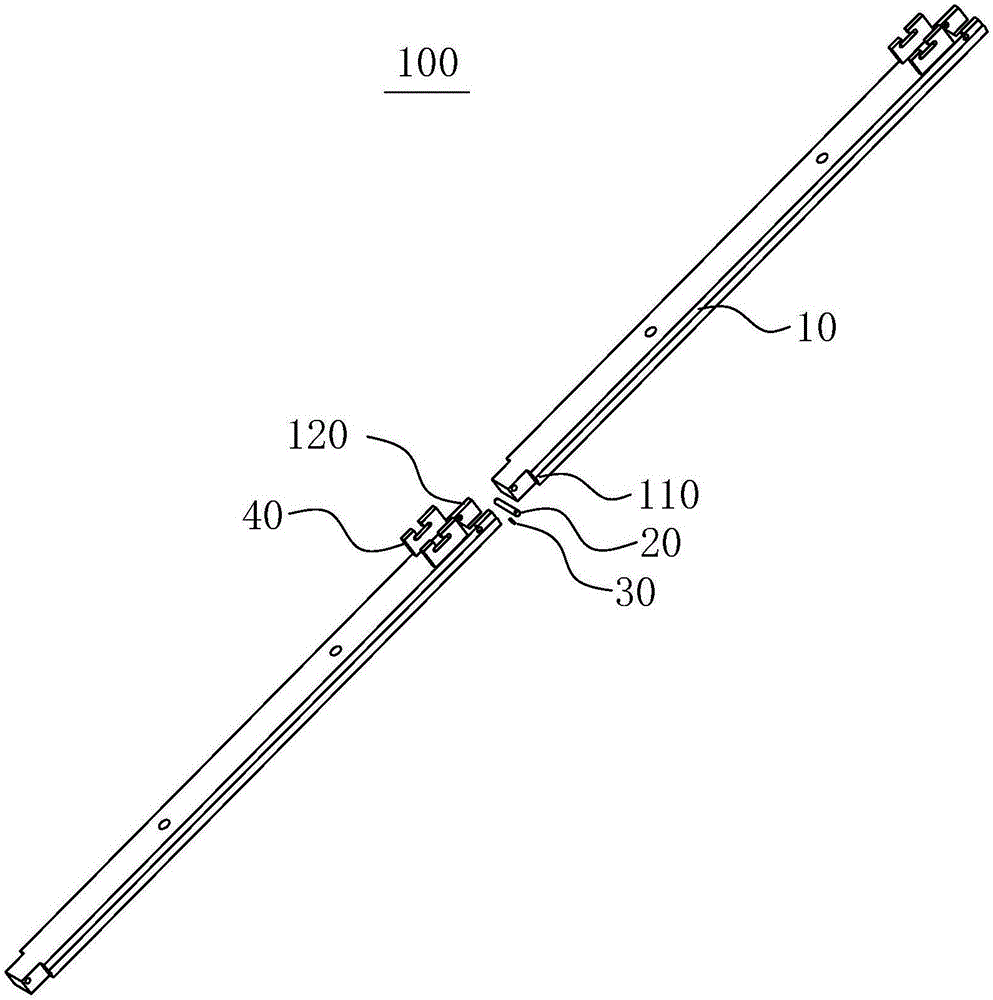

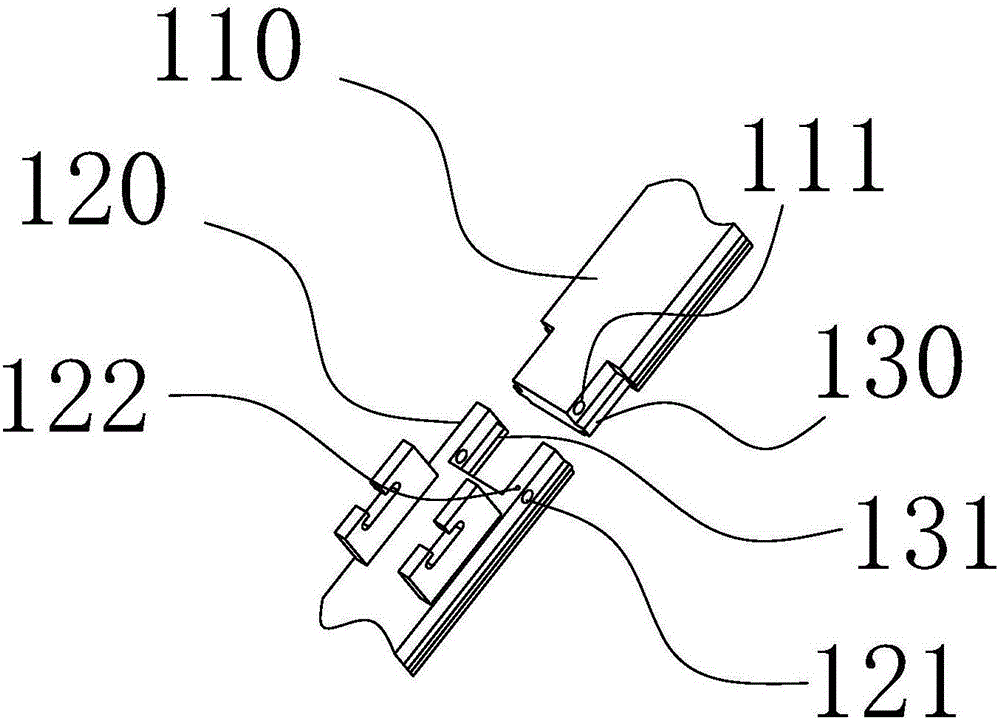

[0036] Please refer to figure 1 , the present embodiment provides a top drive guide rail assembly 100, including a connector 20, a stopper 30 and at least two groups of guide rail units 10, two adjacent groups of guide rail units 10 are connected by the connector 20 and form a connection portion, the connection portion It includes a first connection part 110 and a second connection part 120 , and the first connection part 110 is plugged into the second connection part 120 . It should be pointed out that the first connecting portion 110 and the second connecting portion 120 are respectively located in two adjacent sets of guide rail units 10 .

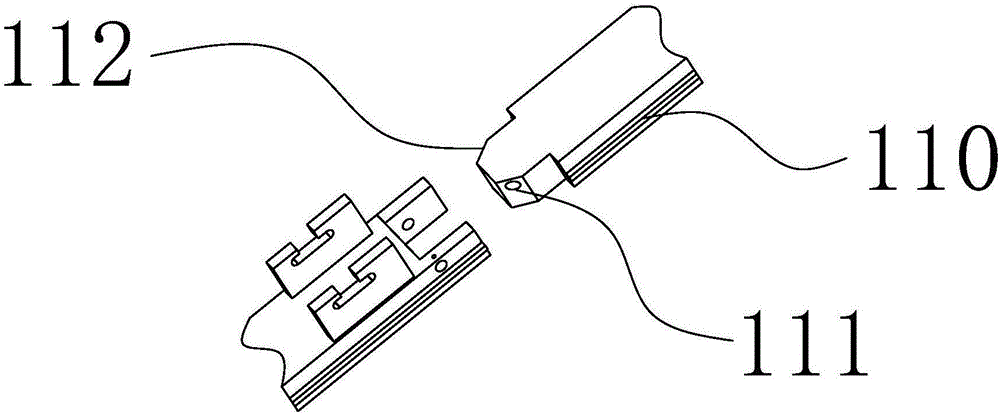

[0037] Such as figure 2As shown, the end of the first connecting portion 110 has a chamfered portion 112, and the chamfered portion 112 is located at the two end faces of the guide rail unit 10 in the width direction, that is, at both ends of the end of the first connecting portion 110 away from the guide rail unit 10. The side is ch...

no. 2 example

[0052] Please refer to Figure 7 , this embodiment provides a top drive guide rail system, including the anti-torque bracket 510, the top drive guide rail hanger 520 and the top drive guide rail assembly 100 provided in the first embodiment, and the rest of the unmentioned parts refer to the first embodiment or existing technology.

[0053] In this embodiment, the top drive rail assembly 100 is connected to the top drive rail suspension frame 520 , and the anti-torque bracket 510 is connected to the top drive rail assembly 100 .

[0054] Further, the top drive guide rail suspension frame 520 includes a guide rail lug and an adjustment plate 530, the guide rail lug is fixed on the bottom plate of the crown block, the adjustment plate 530 and the guide rail lug are connected by a U-shaped ring, and the adjustment plate 530 is connected to the top drive guide rail assembly 100 connect. Such as Figure 8 As shown, the adjustment plate 530 includes an adjustment plate body, a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com