Motor drivers, servo drives and CNC machine tools

A motor driver and comparator technology, applied in the direction of control of electromechanical transmission, motor generator control, control of electromechanical brakes, etc., can solve the problems of low motor system response frequency band, low control signal frequency, large motor operating loss, etc., to achieve improved The effect of operating efficiency, improving the response frequency band, and strong dynamic anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

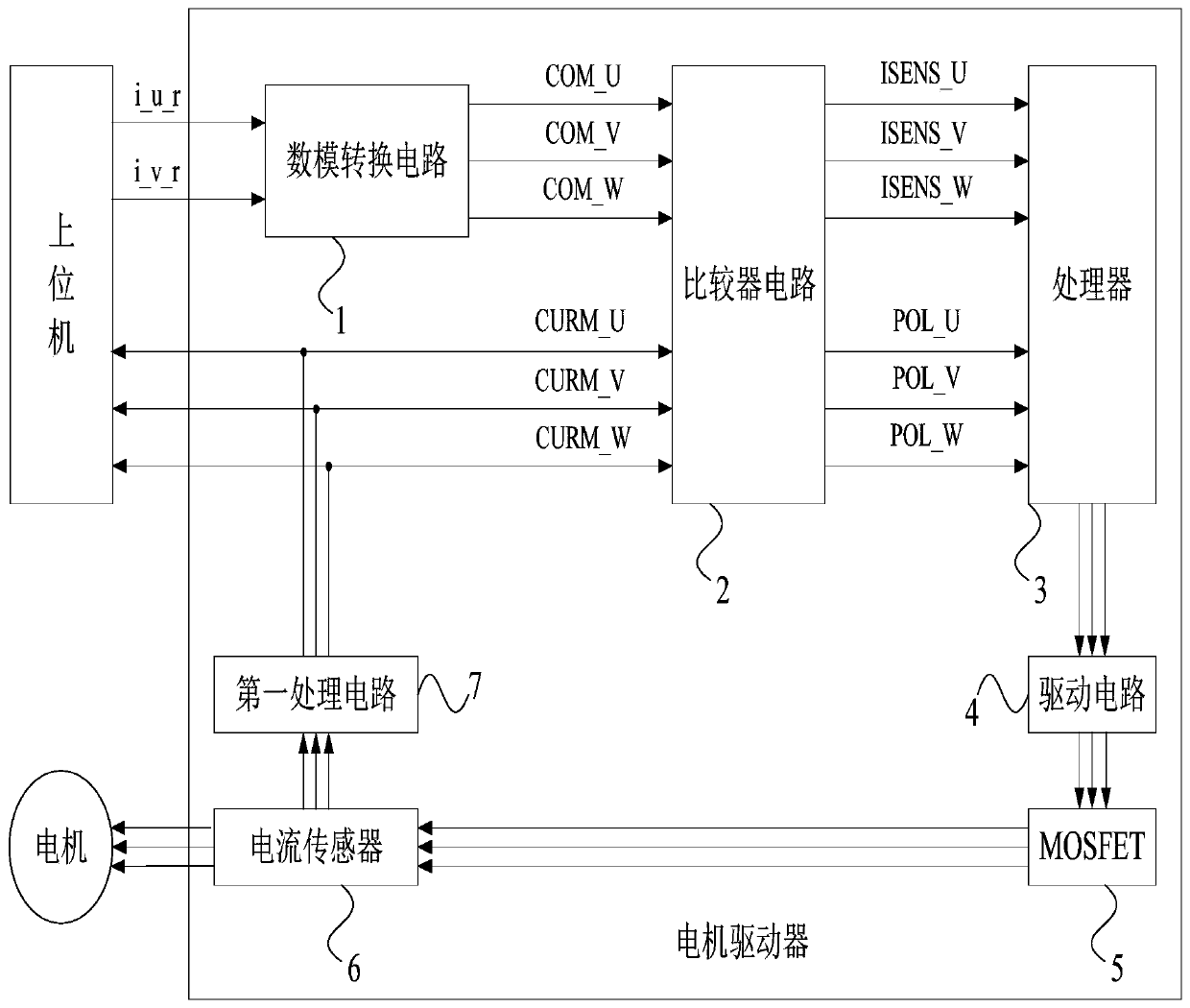

[0033] Such as figure 1 As shown, the motor driver of the present invention includes a digital-to-analog conversion circuit 1, a comparator circuit 2, a processor 3, a drive circuit 4, a MOSFET 5, a current sensor 6 and a first processing circuit 7 electrically connected in sequence;

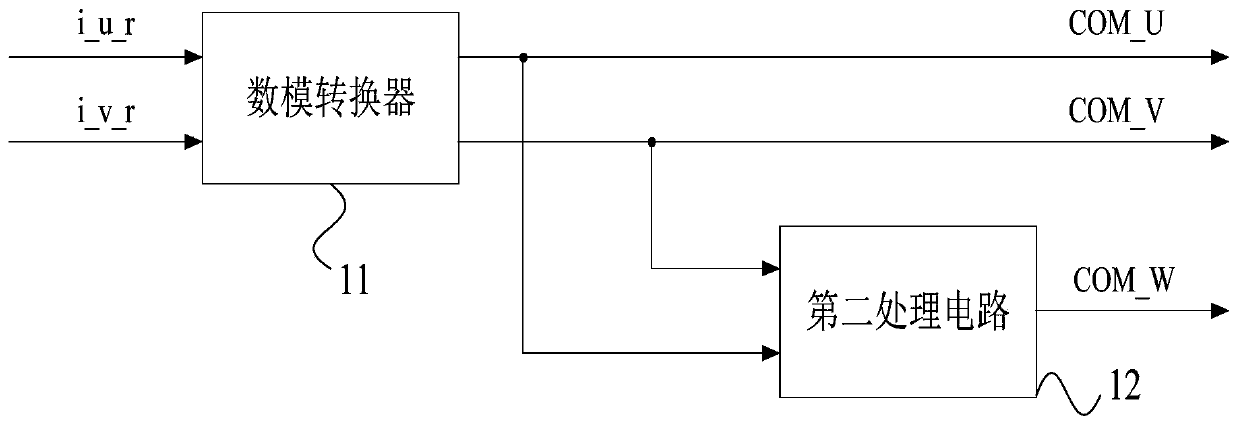

[0034] The digital-to-analog conversion circuit 1 is used to receive the U-phase command current digital signal (i_u_r) and the V-phase command current digital signal (i_v_r) sent by the external host computer and convert them into U-phase command current analog signals (COM_U) and V-phase A command current analog signal (COM_V), and generate a W-phase command current analog signal (COM_W) according to the U-phase command current analog signal (COM_U) and the V-phase command current analog signal (COM_V);

[0035] Such as figure 2 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com