Jetting helment structure with inbuilt shielding plate

A sun visor, jet technology, used in helmets, helmet caps, clothing, etc., to solve problems that do not allow very safe and precise ways to operate or drive sun visor systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

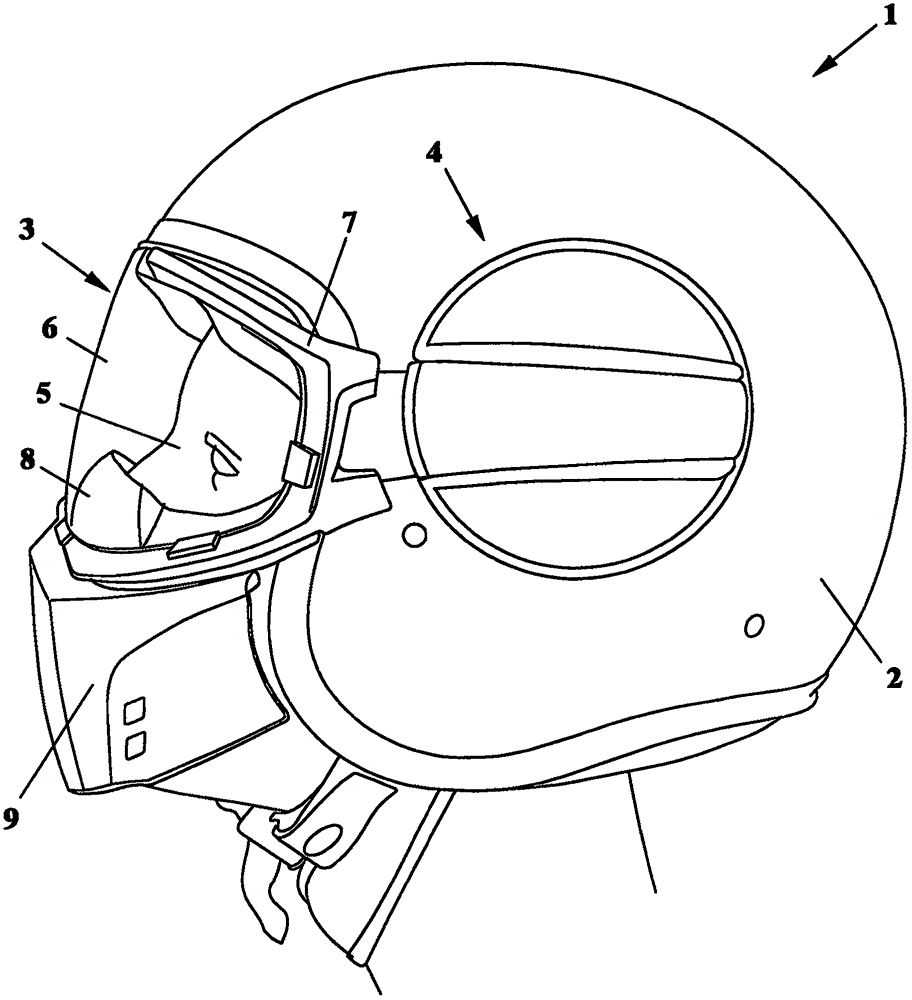

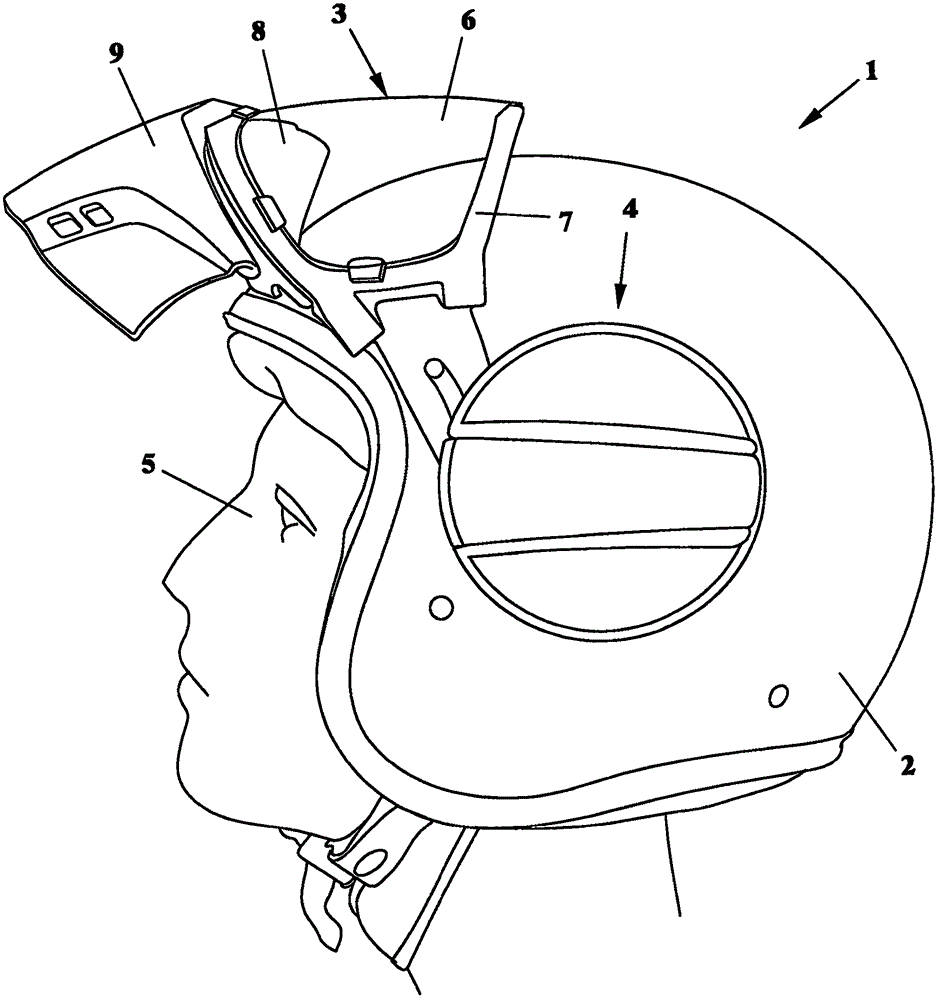

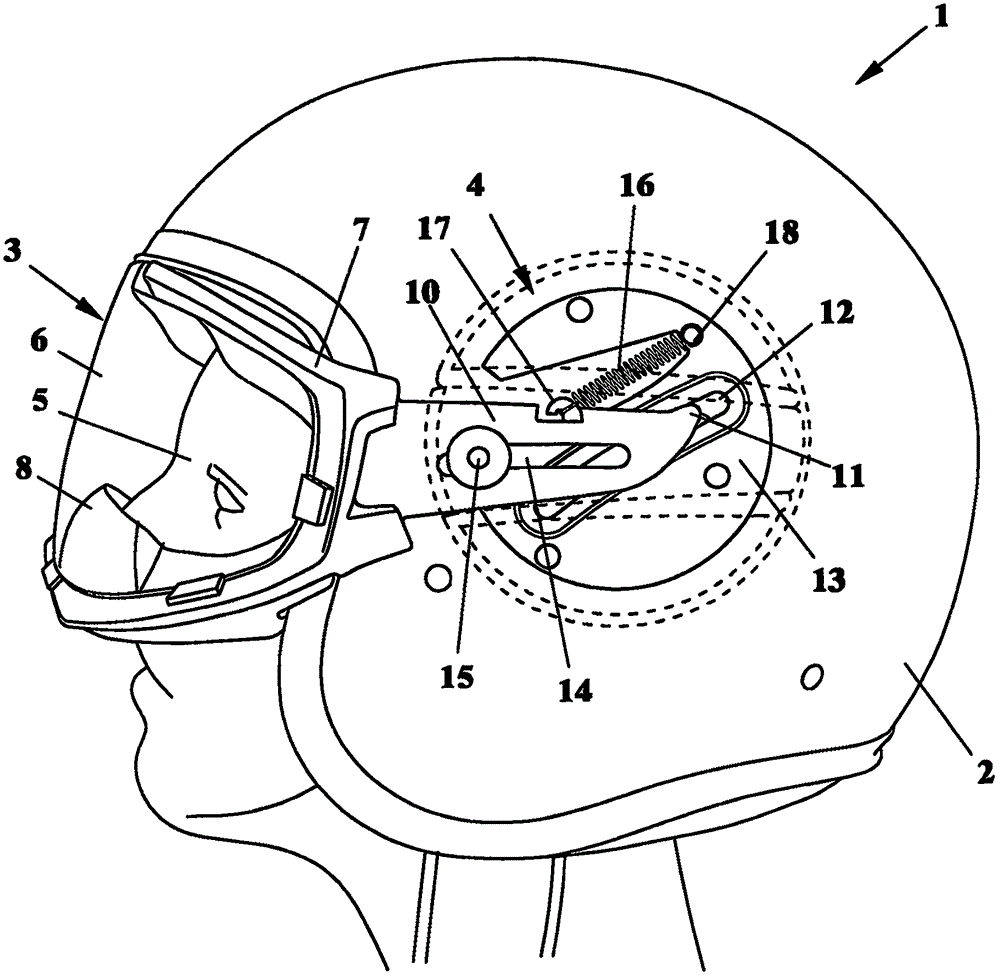

[0025] Referring to the reference numerals of the above-mentioned figures, the structure of the jet helmet according to the present invention, generally indicated by the reference numeral 1, comprises a helmet visor 2 at the front, in use, and a helmet visor system. or wearer's face, said helmet visor system generally indicated by reference numeral 3 .

[0026] The helmet visor system 3 is coupled to the helmet visor body 2 by a rotational (swing) linkage generally indicated by reference numeral 4, thereby defining at least two end positions: namely, a fully closed position and a fully open position, in which In the fully closed position the visor system is arranged on the helmet wearer's face 5 and is recessed into the contour or shape of the helmet body 2, in the fully open position the visor system faces upwards. Flip out of the contour or shape of the helmet body and out of the field of view of the helmet user or wearer.

[0027] According to the invention, the visor syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com