Multi-channel cooling bed charging device and cooling bed

A multi-channel, cooling bed technology, applied in cooling beds, metal processing equipment, metal rolling, etc., can solve the problem that the steel device on the cooling bed cannot be divided into steel, etc., and achieve the effect of simple structure, novel concept, and reasonable and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

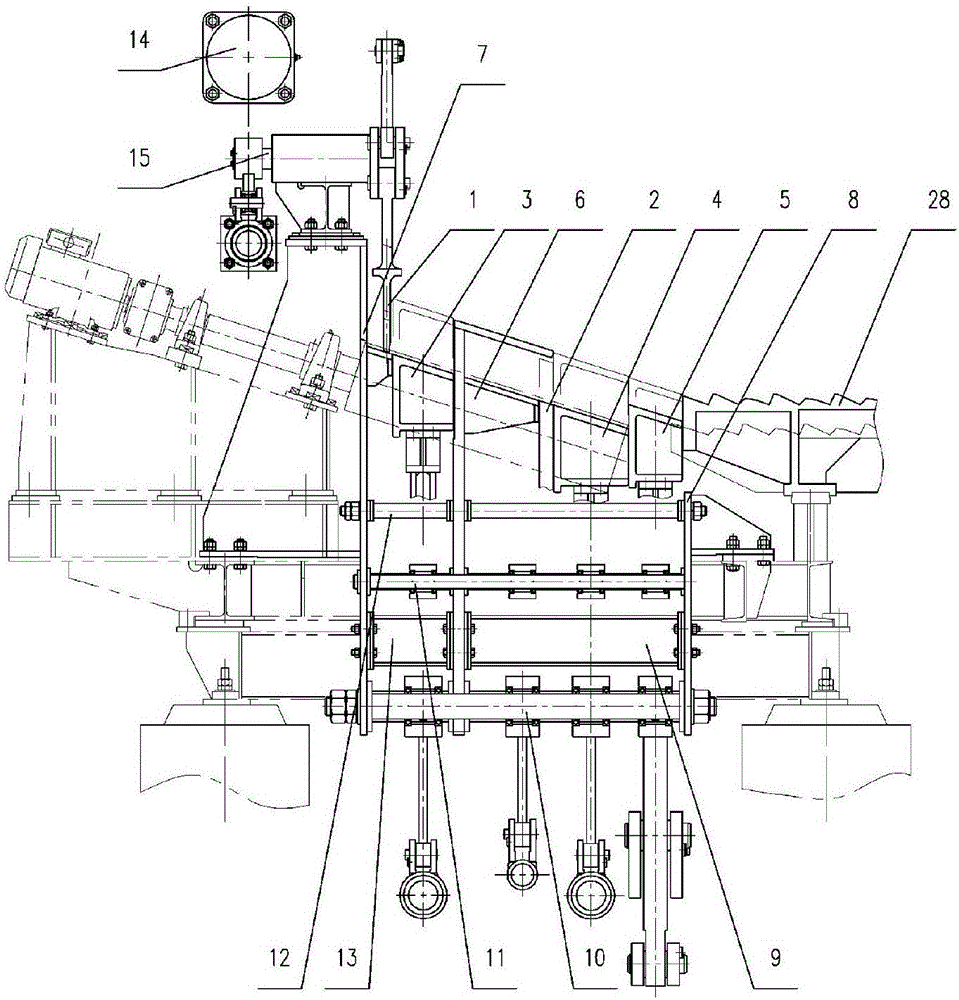

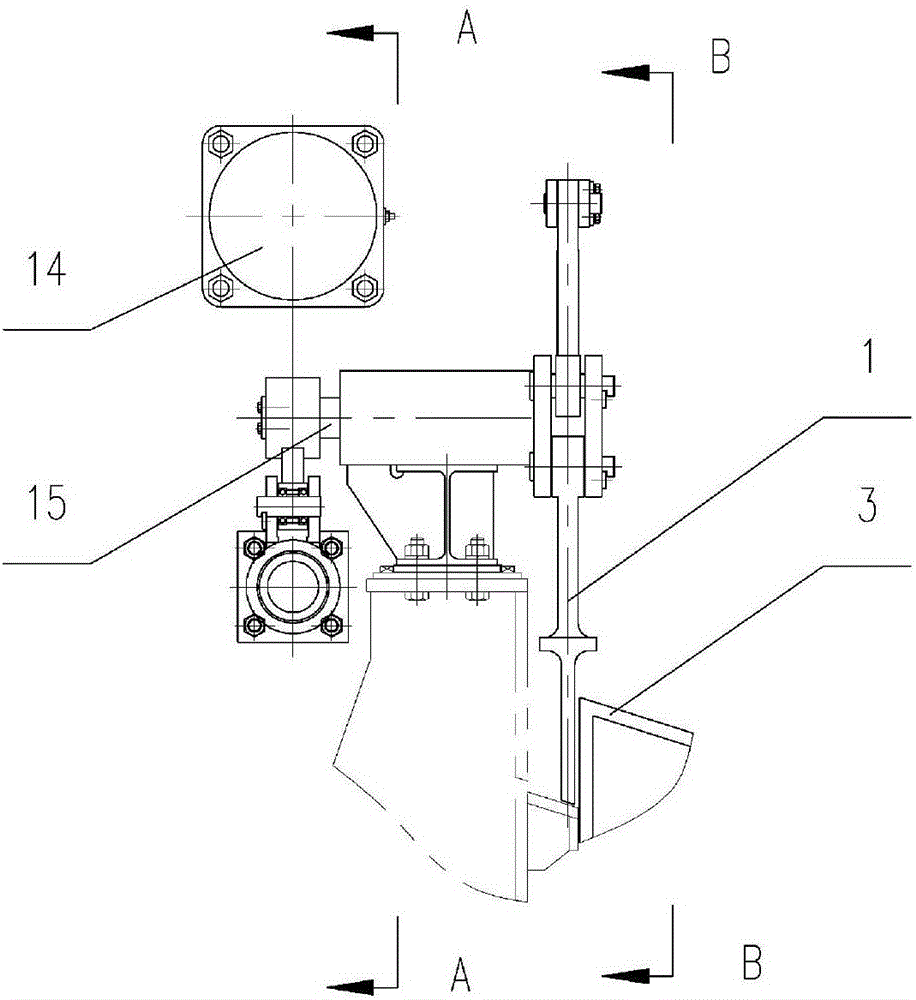

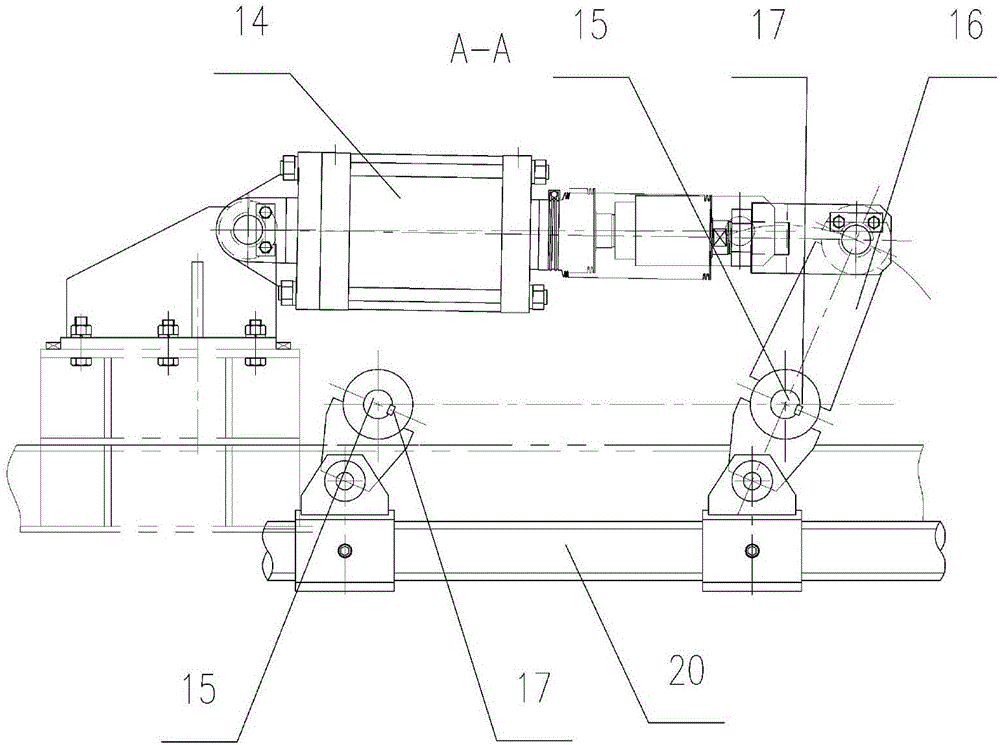

Method used

Image

Examples

Embodiment 1

[0035] For larger gauge rolling pieces (such as round steel, angle steel, etc.) that do not need to be split and rolled, such as Image 6 As shown, the method of loading steel is as follows:

[0036] In the first step, the first skirt plate 1 and the first skirt plate 2 are both located at the high position, and the third skirt plate 3, the fourth skirt plate 4 and the fifth skirt plate 5 are all located at the low position. At this time, the first rolling piece #1 Enter into the third steel inlet channel formed by the first skirt plate 2 and the guide plate 6, and stop quickly after braking;

[0037] In the second step, the first skirt board 1 is at a high position, and the second skirt board 2 moves to a low position. At this time, the top slopes of the guide board 6, the first skirt board 2 and the fourth skirt board 4 are on the same slope and stay on the first The rolling piece #1 in the third steel channel slips down along this inclined plane and stays in the fourth steel cha...

Embodiment 2

[0046] For rolling pieces that need to be split and rolled, such as Figure 7 As shown, the method of loading steel is as follows:

[0047] In the first step, the first skirt plate 1 and the fifth skirt plate 5 are both located at the high position, and the second skirt plate 2, the third skirt plate 3, and the fourth skirt plate 4 are all located at the low position. At this time, the rolled one The rolling piece B1 enters the second steel inlet channel formed by the third skirt plate 3 and the guide plate 6, and stops after rapid braking; another rolling piece A1 that is cut and rolled enters the fourth skirt plate 4 and the fifth skirt plate 5 In the fourth steel channel formed, stop quickly after braking;

[0048] In the second step, the first skirt plate 1 is moved to the low position, the second skirt plate 2 is moved to the high position, and the third skirt plate 3 and the fourth skirt plate 4 are both moved to the middle position. The piece B2 enters the first fixed seat ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap