Long-span welding belt threading mechanism, welding belt supply device and stringer

A long-span, welding strip technology, used in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the interference and distance of the welding strip, and the welding strip will fall after it is loosened or used up and affects other processes. Problems such as work and welding ribbons intertwined with each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments. Obviously, the accompanying drawings in the following description are some embodiments of the present invention. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

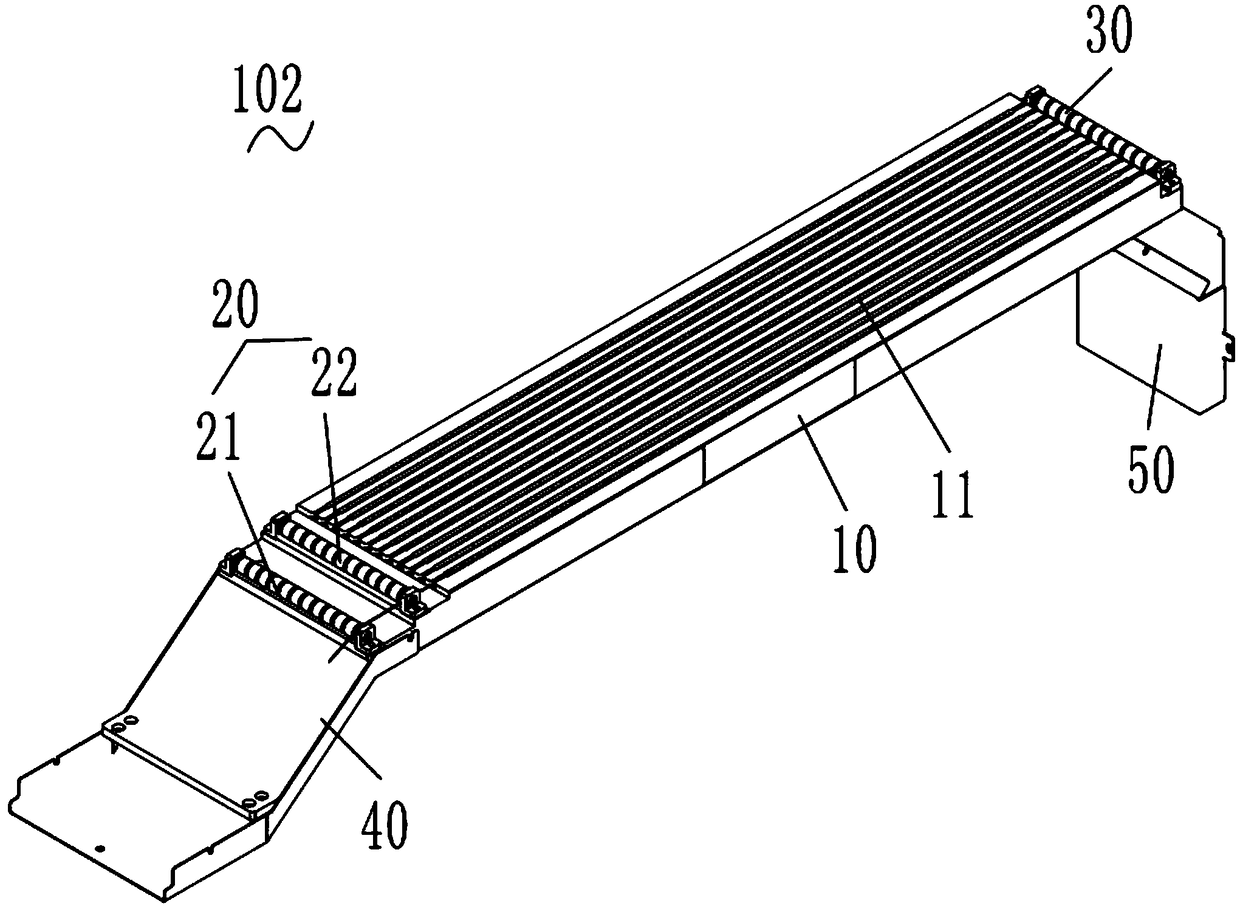

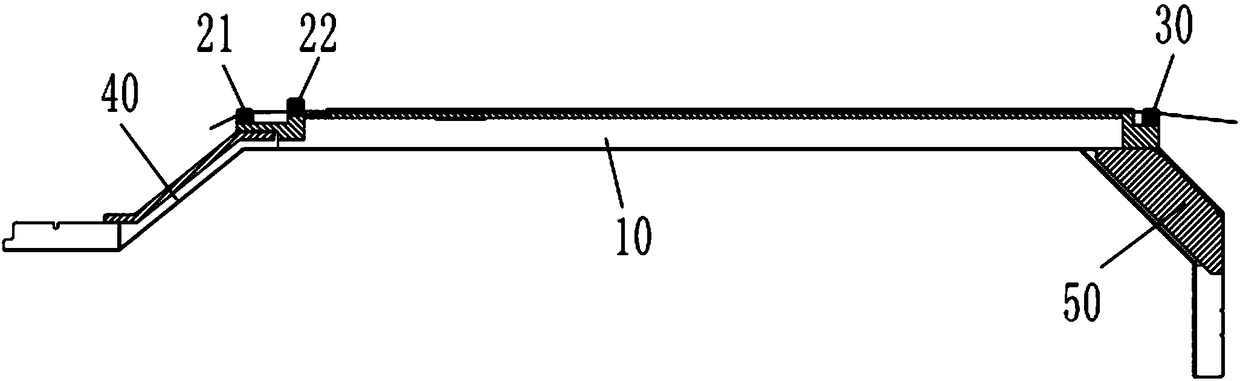

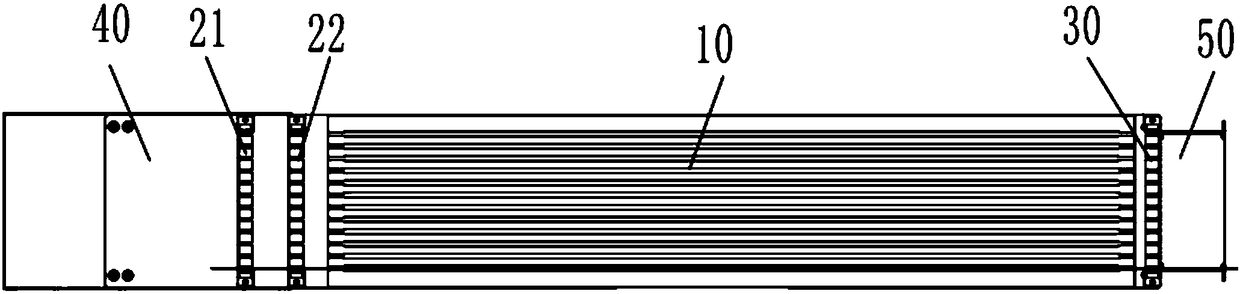

[0030] see figure 1 , the embodiment of the present invention provides a long-span welding ribbon threading mechanism 102, including a center beam 10, an input guide mechanism 20 arranged at the input end of the center beam 10, an output guide mechanism 30 arranged at the output end of the center beam 10, The input guide mechanism 20 and the output guide mechanism 30 are all fixedly connected with the middle beam 10, the middle beam 10 is a strip shaped body arranged along a straight line direction, and on the upper surface of the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com