A wear-resistant and variable friction tire based on shape memory polymer

A memory polymer and friction technology, which is applied to tire parts, reinforcement layers of pneumatic tires, tire treads/tread patterns, etc., can solve the problem of limited effects of wear resistance and anti-skid functions, cumbersome implementation process, and high cost. problems, to achieve the effect of improving wear resistance and service life, trigger mode and operation mode are simple, and improve wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

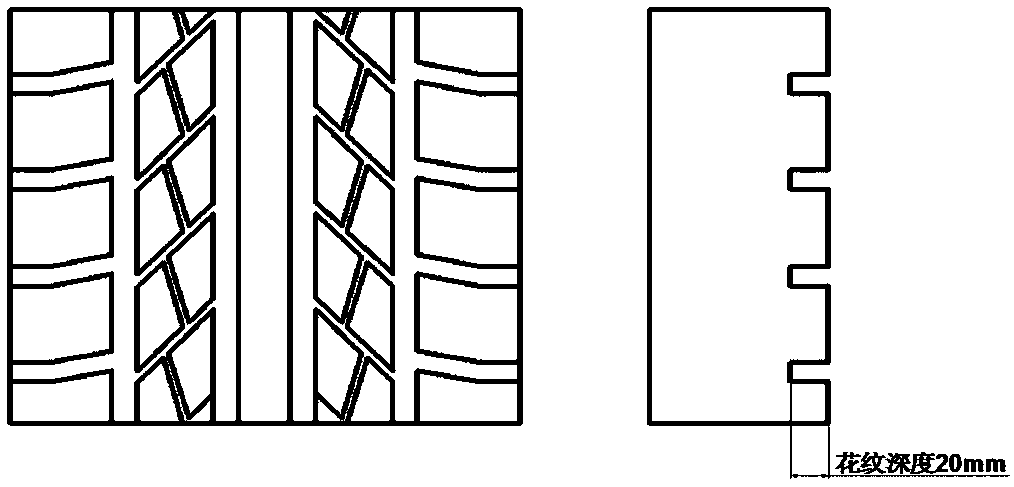

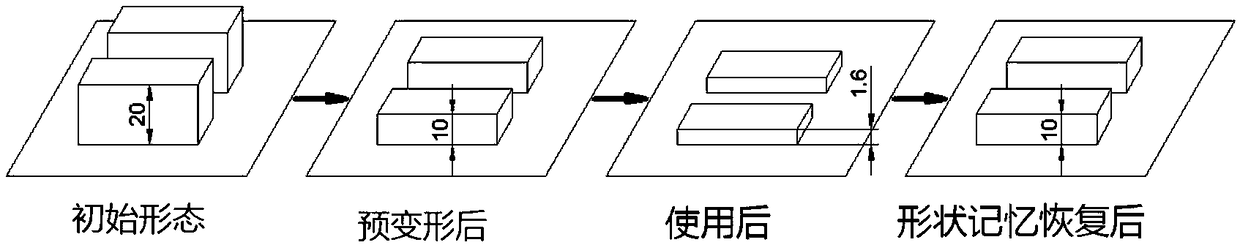

[0024] combined with figure 1 and 2 , a wear-resistant and variable-friction tire based on shape-memory polymers, driven by heating. Automobile tires are made of shape-memory butadiene rubber reinforced with carbon black particles, and the tread depth on the tire surface is 20mm such as figure 1 shown. The tire is heated, and when the temperature reaches about 125°C, the tire surface pattern undergoes compression pre-deformation. After the pre-deformation, the depth of the pattern is 10mm. After the temperature drops to room temperature, the tire surface spontaneously maintains the deformed shape. The pattern depth after pre-deformation can be well adapted to ordinary road surfaces. When the tire stroke reaches a high value and is greatly worn and the surface pattern depth is close to 1.6mm, the surface of the tire can be heated. When the temperature rises to about 125°C, the pattern on the tire surface will recover its shape and its depth will increase. As large as about ...

Embodiment 2

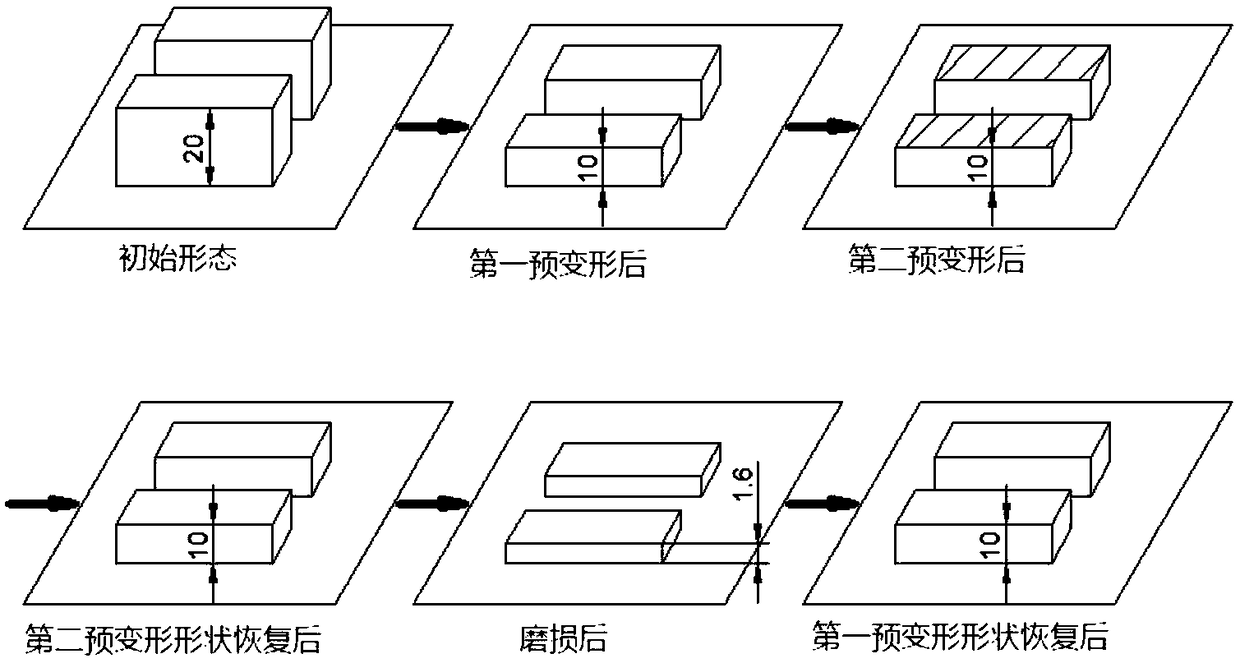

[0026] combined with figure 1 and 3 , a wear-resistant and variable-friction tire based on shape-memory polymers, powered by electricity. Car tires are made of carbon powder-enhanced shape-memory butyl rubber, and the tire surface pattern depth is 20mm, such as figure 1 shown. The tire is heated, and when the temperature reaches about 130°C, the tire surface pattern is compressed and pre-deformed, and the depth of the pattern after pre-deformation is 10mm is the first pre-deformation. When the car encounters rainy and snowy weather and other road surfaces that become smooth during driving, the tire can be driven through the metal plate mold with fine lines on the surface, and fine lines with a depth of 5mm and a width of 1.5mm will appear on the convex surface of the tire pattern. The pattern is the second pre-deformation. At this time, the pre-deformation of the fine lines on the convex surface of the tire pattern increases the friction between the tire and the ground, an...

Embodiment 3

[0030] combined with Figure 4 and 5 , a wear-resistant and variable-friction tire based on shape-memory polymers, powered by electricity. Car tires are made of carbon fiber-reinforced shape memory butyl rubber. The surface pattern depth of the tire is 26 mm, and there are fine lines with a depth of 5 mm and a width of 1.5 mm on the raised surface of the pattern, such as Figure 4 shown. Heat the tire. When the temperature reaches about 130°C, the pattern on the tire surface will undergo compression pre-deformation. After the pre-deformation, the depth of the pattern is 13mm, which is the first pre-deformation; Embossing pre-deformation treatment is carried out on the convex surface of the tire surface pattern, so that the fine-grained surface of the tire convex surface is flattened, but the overall depth of the tire pattern remains unchanged. This is the second pre-deformation; the tire is put into use after cooling to room temperature . During use, when the car encounter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com