Split quick cleaning device suitable for environmental-friendly garbage can

A technology for cleaning devices and trash cans, which is applied in the direction of trash cans, garbage cleaning, garbage collection, etc., which can solve the problems of inconvenient cleaning, unhygienic, unfavorable environmental protection, etc., and achieve the effect of good cleaning effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

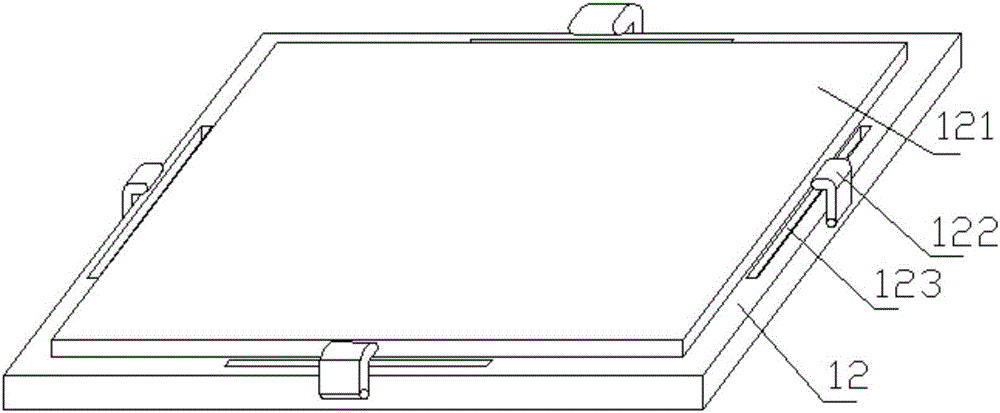

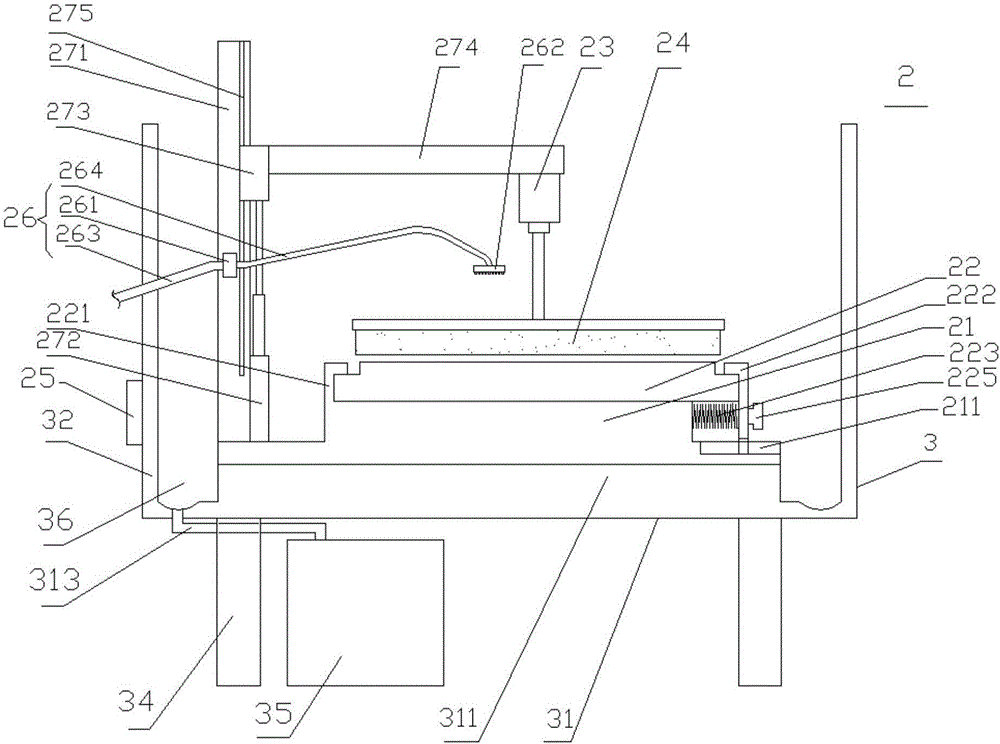

[0032] The bucket bottom cleaning equipment 2 includes a support platform 21, a cleaning workbench 22 fixed on the support platform 21 and corresponding to the bucket bottom 12, and a first cleaning brush 24 located above the cleaning workbench 22 and having a circular cross section. , the first driving motor 23 connected to the first cleaning brush 24 and used to drive the first cleaning brush 24 to rotate, the first lifting drive device for driving the first driving motor 23 to reciprocate in a straight line up and down, spraying water towards the cleaning table 22 The first water spray assembly 26, the first PLC controller 25. The diameter of the first cleaning brush 24 is greater than the width of the clamping portion 121 of the bucket bottom 12 , and the first driving motor 23 and the first lifting driving device are respectively electrically connected to the first PLC controller 25 .

[0033] One end of the cleaning workbench 22 in the horizontal direction extends upward...

Embodiment 2

[0039] Such as Figure 4 As shown, the difference between the present embodiment and the first embodiment lies in that the first lifting drive device in the barrel bottom cleaning device 2 of the present embodiment is different from the first embodiment. Specifically, the first lifting drive device of this embodiment includes a drive cylinder 282 suspended above the first drive motor 23 through a support frame 281, the bottom end of the support frame 281 is fixed on one side of the support platform 21, and the drive cylinder The telescopic end at the bottom of 282 is fixed with a fixed plate 283 , the first driving motor 261 is fixed on the fixed plate 283 , and the driving cylinder 282 is electrically connected to the first PLC controller 25 . The linear reciprocating lifting motion of the first driving motor 23 is realized by controlling the first PLC controller 25 to drive the cylinder 282 to expand and contract.

[0040] The above two embodiments have introduced two techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com