Crystal oscillator feeding mechanism based on flat forming conveyance

A technology of feeding mechanism and crystal oscillator, which is applied to conveyors, conveyor objects, vibrating conveyors, etc., can solve problems such as difficulty, and achieve the effect of simple structure, completely practical structure and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

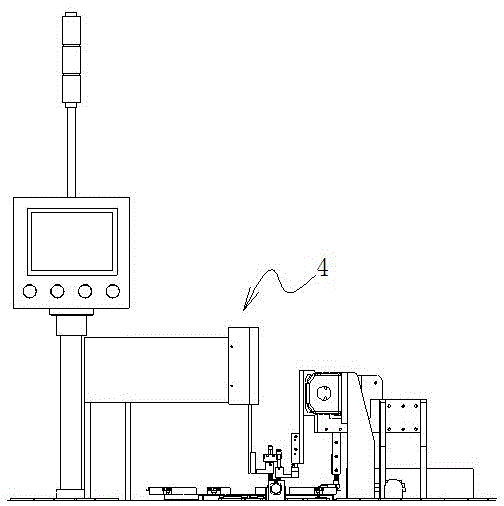

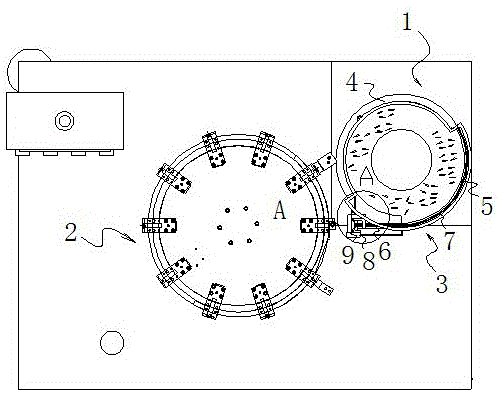

[0014] A crystal vibration feeding mechanism based on flat forming and conveying, including a vibrating device and a forming device 2 arranged beside the vibrating device 1 , and a conveying device 3 is also arranged between the vibrating device 1 and the forming device 2 .

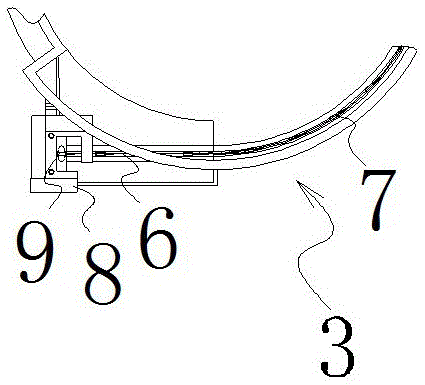

[0015] The vibrating device 1 includes a vibrating plate 4 and a vibrating plate conveying track 5 that is circumferentially arranged on the edge of the vibrating plate 4, and the conveying device 3 includes a conveying track 6 that is connected to the above-mentioned vibrating plate conveying track 5 at one end, and the conveying track 6 The other end is connected with the forming device 2, and the vibrating plate conveying track 5 and the conveying track 6 are provided with a crystal oscillator horizontal groove 7 for laying the crystal oscillator flat, and the conveying track 6 is also provided with a stopper 8 for adjusting the orientation of the crystal oscillator. A crystal oscillator adjustment chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com