Overrun clutch capable of prolonging service life

A technology of overrunning clutches and longevity, which is applied to clutches, one-way clutches, mechanical equipment, etc., can solve the problems of not getting stuck, troublesome replacement, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

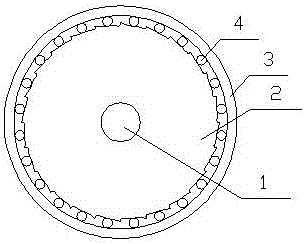

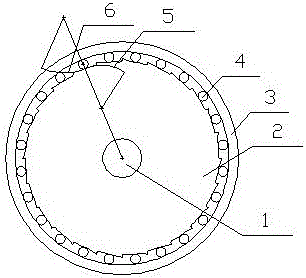

[0009] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0010] As shown in the figure, an overrunning clutch capable of prolonging service life is provided, including: a driving shaft 1, a driving helical gear 2, a driven ring 3 and a roller 4, the driving shaft 1 is fixedly connected to the driving helical gear 2, and the driving A roller 4 is arranged between the helical toothed plate 2 and the driven ring 3, and the helical teeth of the driving helical toothed plate 2 are provided with an inward arc 6 and an outward arc 5. The center point of the inner arc 6 and the center point of the outward arc 5 are on a straight line; in this way, when the speed of the driven ring exceeds that of the driving helical gear, the upper wedge surface of the helical tooth slides downward in an arc shape, and the loosening is faster. When the rotating speed of the active helic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com